Wholesale Price Water Filling Line - Automatic Detection Reagent Liquid IVD Test Tube Filling Machine – Ipanda

Wholesale Price Water Filling Line - Automatic Detection Reagent Liquid IVD Test Tube Filling Machine – Ipanda Detail:

Product Display

Overview

filling and capping machine is a compact filling line equipment.which is mainly applicable to the filling and capping of plastic bottles in medical, pharmaceutical and chemical industries. Automatically complete filling. capping, capping, bottle out, etc.The equipment is suitable for products that are easy to pour and jam bottles on the conveyor belt.

It’s a series of products specially designed for biochemical reagent bottles. It is composed of host, rotary conveying,clamping conveying and bottle holder. It is suitable for all products in Hitachi series.The design adopts peristaltic pump for filling, and the measurement is accurate; The swing arm is used to hook the upper cover, and the positioning is accurate;Pneumatic control is adopted to clamp the screw cap, which will not cause wear to the shape of the bottle cap;The height and clamping force of the screw head are easy to adjust and control.

Parameter

| Applied Bottle | 0.5-10 ml |

| Productive Capacity | 20-60pcs/min

|

| Filling Tolerance | 1% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 110/220/380V ,50/60HZ |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

Features

* All electrical components arewell-known brands.

* Disc positioning filling, which is stable and reliable.

* High-precision cam indexer controlto reach precise positioning.

* It is made of SUS304 or316L stainless steel, which meets GMP requirements.

* Man-machine interface settingwith PLC control has intuitive and convenient operation

* Accurate loadingand automatic counting.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping.

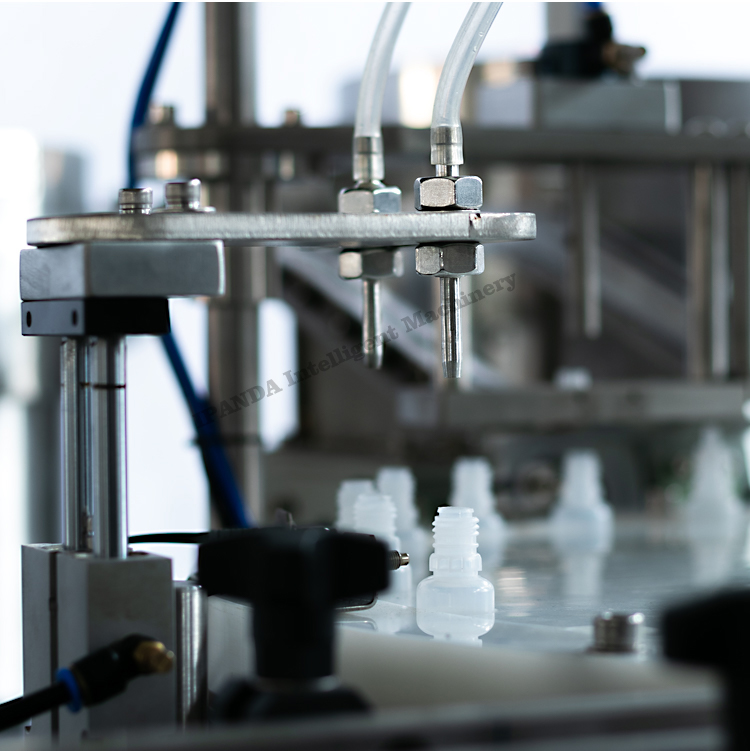

The Machine Details

This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design;

Peristaltic pump filling, high cleanliness, in line with medical health standards.

Double head filling, double head capping, greatly improve the efficiency.

Adopt a swing lifting cam, lifting and swinging automatically insert the cap, the cap is automatically arranged by the vibration plate and automatically sent to the uploading cap station through the loading cap

The capping head adopts mechanical claw cover (servo motor controlled capping claw),the capping head Torque and torque are controlled by servo, and torque servo control.

Cap vibrating plate used to arrange cap automatically

All action is controlled by PLC and Touch screen. The surface of machine is SUS304, material contacted with liquid is 316L stainless steel, can be connect with labeling machine.

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company’s equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of “Good quality , Good service, Good prestige”. We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our factory,and see the machine running.

Castomized service

1.We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

3..We provide one year warranty

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .12 Months guarantee and life-long technical support.

6.Your business relationship with us will be confidential to any third party.

7. Good after-sale service offered, please get back to us if you got any questions.

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Wholesale Price Water Filling Line - Automatic Detection Reagent Liquid IVD Test Tube Filling Machine – Ipanda , The product will supply to all over the world, such as: Belgium, Florida, New Delhi, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.