Wholesale Price Honey Filling Machine - Automatic Paste Shampoo Liquid Soap Cleaner Filling Machine – Ipanda

Wholesale Price Honey Filling Machine - Automatic Paste Shampoo Liquid Soap Cleaner Filling Machine – Ipanda Detail:

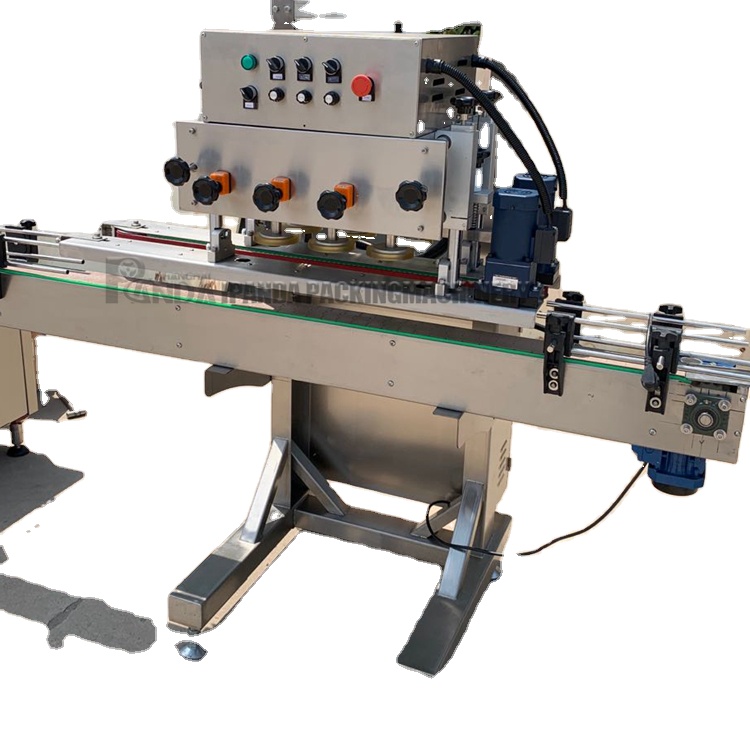

Product Display

Overview

Automatic shampoo filling machine

This type of machine can be used for fixed amount small package filling,straight line type filling, metical, electric, apparatus control of all sorts of viscous and no viscous, erosive liquid, such as plant oil chemical, liquid, daily chemical industry. It is rather simple and rapid to change items, the design is quite distinct, the property is Very advantageous, its appearance corresponds to international concept for mechanical equipment.

Parameter

|

Filling nozzle number |

2/4/6/8/12 customized |

|

filling volume |

100-1000ml(can be customized) |

|

filling speed |

15-100bottles/min |

|

filling accuracy |

≤±1% |

|

capping rate |

≥98% |

|

total power |

3.2kw |

|

power supply |

1ph .220v 50/60HZ |

|

machine size |

L2500*W1500*H1800mm (customized) |

|

Net weight |

600kg(customized) |

Advantage

1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize.

2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry.

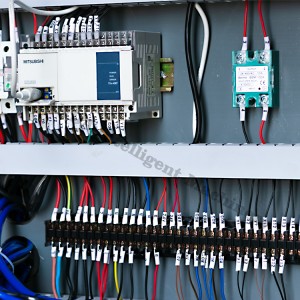

3. PLC control system, frequency conversion adjusting speed, high degree automation.

4. No bottle, no filling, auto count the quantity. And have the anti-drop device.

5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate.

6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble.

7. The whole machine is suitable bottles in different size, easy adjusting, and can be finished in short time.

Features

1. Adopts positive displacement plunger pump for filling, high precision, large range of adjusting dosage, can regulate filling amount of all the pump body as a whole, also can adjust a single pump slightly, quick and convenient.

2. Plunger pump filling system has features of no adsorbing drugs, good chemical stability, high temperature resistance, corrosion resistance, abrasion resistance, long service life, has unique advantages when fill some corrosive liquid.

3. Machine can be customized with 4/6/8/12/14/etc filling heads according to customer’s production capacity.

4. Used for various viscosity liquid filling, frequency control,

5. Machine body is made of 304 stainless steel, full compliance with GMP standard.

Application

50ML-5L plastic bottles, glass bottles, round bottles, square bottles, hammer bottles are applicable

Hand sanitizer, shower gel, shampoo, disinfectant and other liquids, with corrosive liquids, paste are applicable.

The Machine Details

Anti drop filling nozzles, save product and keeps the machine clean.made of SS304/316.we customize 4/6/8 filling nozzles, for different requested filling speed.

Adopt piston pump

It’s suitable for sticky liquid, the adjustment of piston in dosage is convenience and quick, the volume only need to be set on the touch screen directly.

PLC control :This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement.

Company information

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

Why Choose Us

Dedication to Research & Development

Experienced Management

Better understanding of Customer requirement

One Stop solution provider with Broad Range Offering

We can supply OEM&ODM design

Continuous Improvement with Innovation

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for Wholesale Price Honey Filling Machine - Automatic Paste Shampoo Liquid Soap Cleaner Filling Machine – Ipanda , The product will supply to all over the world, such as: New Delhi, Sheffield, Miami, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.