Special Design for Gravity Bottle Filling Machine - Automatic Shampoo Bottle Filling and Capping Machine – Ipanda

Special Design for Gravity Bottle Filling Machine - Automatic Shampoo Bottle Filling and Capping Machine – Ipanda Detail:

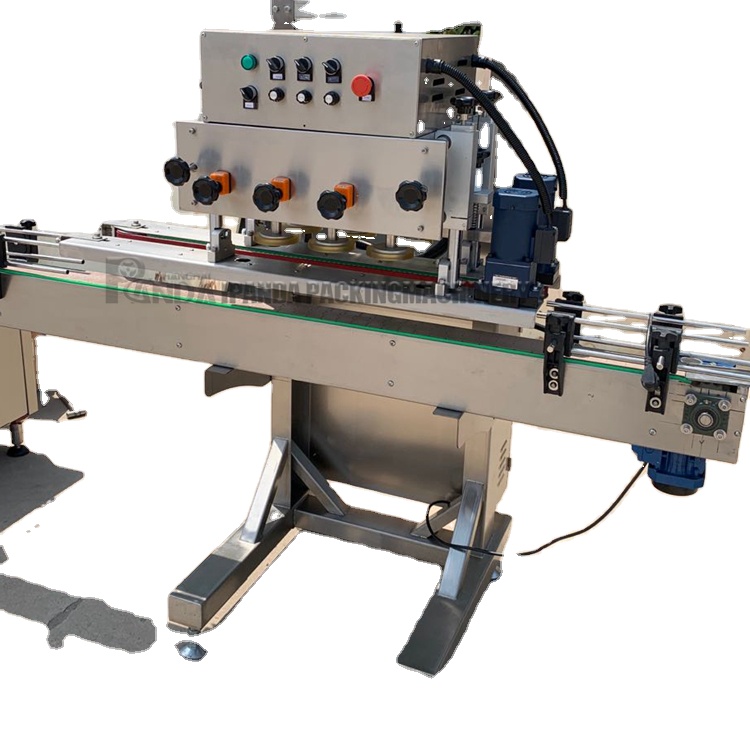

Product Display

Overview

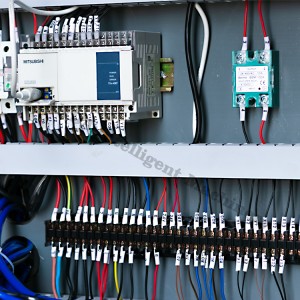

This machine have been widely used in manufacturing, chemical, food, beverage and other industries. It is especially designed for high viscosity liquid Easily controlled by computer (PLC), touch screen control panel. It is characterized by its totally close from, submerged filling, high measurement accuracy, compact and perfect feature, liquid cylinder and conduits disassemble and clean. It may also suited various figure containers. We utilize high-quality stainless steel frames, international famous brand electrical components, the machine is applied to GMP standard requirement.

Parameter

|

Material |

SUS304 and SUS316L |

||||

|

Filling range |

10-100ml/ 30-300ml/ 50-500ml/ 100-1000ml/ 250-2500mml/ 300-3000ml/ 500-5000ml (can be customized) |

||||

|

Fillling heads |

4 |

6 |

8 |

10 |

12 |

|

Filling speed |

About 2000-2500 |

About 2500-3000 |

About 3000-3500 |

About 3500-4000 |

About 4000-4500 |

|

Filling precision |

±0.5-1% |

||||

|

Power |

220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries) |

||||

|

Air pressure |

0.4-0.6Mpa |

||||

| Machine Size(L*W*Hmm) | 2000*900*2200 | 2400*900*2200 | 2800*900*2200 | 3200*900*2200 | 3500*900*2200 |

|

Weight |

450Kg |

500Kg |

550Kg |

600Kg |

650Kg |

Advantage

1. All pipe use quick-change connector.

2. Height and space between filling heads can be changed quick and easy to operate.

3. All filling valve use ESG valve instead of traditional valve by general manufacturer.

4. All filling heads can be diving from the bottom of bottle to start filling.

Features

1. Adopts positive displacement plunger pump for filling, high precision, large range of adjusting dosage, can regulate filling amount of all the pump body as a whole, also can adjust a single pump slightly, quick and convenient.

2. Plunger pump filling system has features of no adsorbing drugs, good chemical stability, high temperature resistance, corrosion resistance, abrasion resistance, long service life, has unique advantages when fill some corrosive liquid.

3. Machine can be customized with 4/6/8/12/14/etc filling heads according to customer’s production capacity.

4. Used for various viscosity liquid filling, frequency control,

5. Machine body is made of 304 stainless steel, full compliance with GMP standard.

Application

50ML-5L plastic bottles, glass bottles, round bottles, square bottles, hammer bottles are applicable

Hand sanitizer, shower gel, shampoo, disinfectant and other liquids, with corrosive liquids, paste are applicable.

The Machine Details

Adopt none-drip and none-silk filling nozzle institution design

Accurate liquid level sensor ,automatic feeding material ,ordinary pressure to fix flow way parameter ,help you to finish accurate filling section

Adopt piston pump

It’s suitable for sticky liquid, the adjustment of piston in dosage is convenience and quick, the volume only need to be set on the touch screen directly.

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for Special Design for Gravity Bottle Filling Machine - Automatic Shampoo Bottle Filling and Capping Machine – Ipanda , The product will supply to all over the world, such as: Florida, Slovakia, Brazil, We always hold on the company's principle "honest, professional, effective and innovation", and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.