-

Automatic Electronic Cigarette Liquid Filling Capping Machine

Overview

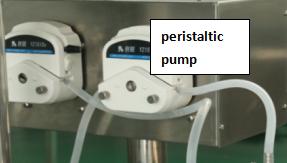

The automatic filling and capping machine is a device designed for bottled liquids . It uses Peristaltic pump filling, positioning type cap feeder, capping, and magnetic moment capping. Using PLC, touch screen control, imported photoelectric detection, high precision, widely used in pharmaceutical, food, chemical, health care products, pesticides and other industries. Made in full compliance with the new GMP requirements.

Features:

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

Please see this video of automatic e-liquid filling and capping machine

We also can supply the automatic e-liquid filling capping labeling machine line

Working process

Bottle unscrambling (optional device)

Peristaltic pump filling (no bottle no filling)

Inner plug loading and press by vibrating plate (no bottle no loading)

Outer cap loading by vibrating plate (no plug no loading)

Outer cap capping auto

Automatic labeling machine (optional device)

Finish bottles collect turntable (optional device)

Can be connected to the cartoning machine (optional device)

It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Main parameter of the machine

Name Filling capping machine Filling volume 5-250ml,can be customized Net weight 550KG Filling heads 1-4 heads,can be customized Bottle diameter Can be customized Filling speed 1000-2000BPH,can be customized Bottle height Can be customized Voltage 220V,380V ,50/60GZ Filling accuracy ±1ml Power 1.2KW Bottle material Glass ,plastic bottle Working pressure 0.6-0.8MP Filling material Eye drop,e-liquid,cbd oil Air consumption 700L per hour Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Remark: In view of our products model different ,widely used in many industries ,in order to improve communication efficiency .so pls note the size weight and name of testing product before send us inquiry .so we can choose the suitable one for you ,send detail and quotation to your email .thank you for your understanding .

-

Automatic Eliquid E-Cigarette Oil Filling Plugging Capping Machine

Overview

This machine is one of the traditional filling stoppering and capping equipment, advanced design, reasonable structure, can automatically complete filling,stoppering and capping process, is suitable for eye drop,eliquid,and other vial bottles such as, no bottle no filling, no bottle no stoppering(plug), and other functions. Can be used stand-alone, and also can be used for filling line. This machine completely accords with the new GMP requirements.

Features:

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

Please see this video of automatic e-liquid filling and capping machine

We also can supply the automatic e-liquid filling capping labeling machine line

Working process

Bottle unscrambling (optional device)

Peristaltic pump filling (no bottle no filling)

Inner plug loading and press by vibrating plate (no bottle no loading)

Outer cap loading by vibrating plate (no plug no loading)

Outer cap capping auto

Automatic labeling machine (optional device)

Finish bottles collect turntable (optional device)

Can be connected to the cartoning machine (optional device)

It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Filling Volume 2-30ml customize Output 30-50BPM Filling Precision ≤±1% Power Supply 380V/50Hz Capping Rate ≥99% Stoppering rate ≥99% Air Supply 1.3 m3/h 0.4-0.8Mpa Power 2.0 kw Weight 550 kg Dimension 1800*1000*1500mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Remark: In view of our products model different ,widely used in many industries ,in order to improve communication efficiency .so pls note the size weight and name of testing product before send us inquiry .so we can choose the suitable one for you ,send detail and quotation to your email .thank you for your understanding .

-

E-Liquid Filling Plugging & Capping Machine with GMP Standards

Overview:

This machine is mainly available to fill Oil, Eye-drop, Cosmetics oil, E-liquid into various round and flat Glass bottles with the range from 10-50ml. High precision cam provides a regular plate to position, cork and cap; accelerating cam makes capping heads going up and down; constant turning arm screws caps; piston measures filling volume; and touch screen controls all action. No bottle no filling and no capping. The machine enjoys high position accuracy, stable driving, precise dosage, and simple operation and also protects bottle caps. Servo motor control peristaltic pump filling for less tham 50ml bottle filling.

If customer want filling 60ml bottle or 120ml bottle also can choose piston cylinder filling. Filling speed will be faster,

If customer want high filling speed. Also can customize Doule work staions ( 2 filling nozzle, 2 capping system , 2 plugging system)ensure high speedPlease see this video of automatic e-liquid filling and capping machine

We also can supply the automatic e-liquid filling capping labeling machine line

Working process

Bottle unscrambling (optional device)

Peristaltic pump filling (no bottle no filling)

Inner plug loading and press by vibrating plate (no bottle no loading)

Outer cap loading by vibrating plate (no plug no loading)

Outer cap capping auto

Automatic labeling machine (optional device)

Finish bottles collect turntable (optional device)

Can be connected to the cartoning machine (optional device)

Features:

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Filling Volume 2-30ml customize Output 30-50BPM Filling Precision ≤±1% Power Supply 380V/50Hz Capping Rate ≥99% Stoppering rate ≥99% Air Supply 1.3 m3/h 0.4-0.8Mpa Power 2.0 kw Weight 550 kg Dimension 1800*1000*1500mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

-

E-Liquid Filling Line Auto Cbd Oil Tincture Bottle Filling Capping Labeling Machine

The automatic filling and capping machine is a device designed for bottled liquids . It uses Peristaltic pump filling, positioning type cap feeder, capping, and magnetic moment capping. Using PLC, touch screen control, imported photoelectric detection, high precision, widely used in pharmaceutical, food, chemical, health care products, pesticides and other industries. Made in full compliance with the new GMP requirements.

-

Automatic Monoblock Filling Stoppering Capping Labeling Machine for E-Liquid

Overview:

The E liquid bottle filling capping machine with best discount for essential oil and e-cigarette liquid is mainly suitable for automatic filling, stoppering and screw capping of electronic cigarette liquid, e-liquid ,eye drops, nail polish, eye shadow, essential oil, with filling volume less then 50 ml. And suitable to glass dropper bottle filling and capping for essential oil automatically. Also suitable to VG ,PG liquid filling and capping.

Please see this video of automatic e-liquid filling and capping machine

Working step:

Automatic feeder for bottles—filling—automatic feeder for cap/plug—capping— out put.Features:

1. This filling and capping machine is multi-function monoblock machine with compact design..

2. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

4. The machine is controlled by PLC and touch screen.

5. It applies Peristaltic pump filling system.

6. Flexible for all kinds of capping heads, screw, press, alu. Roll.

7. It is ideal equipment for low-capacity requirement. It can tighten caps automatically.

8. All the parts which touch the material are made of high quality stainless steel, and the surface has been polished, no pollution to the surrounding.

It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Filling Volume 2-30ml customize Output 30-50BPM Filling Precision ≤±1% Power Supply 380V/50Hz Capping Rate ≥99% Stoppering rate ≥99% Air Supply 1.3 m3/h 0.4-0.8Mpa Power 2.0 kw Weight 550 kg Dimension 1800*1000*1500mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

-

Automatic Small Bottle Eye Drop Filling Plugging Capping Machine Production Line

Overview:

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

Please see this video of automatic eye drop filling and capping machine

Working step:

Automatic feeder for bottles—filling—automatic feeder for cap/plug—capping— out put.

feature:

1.Adopt human-computer interface,PLC controller,easy to operate

2.Use frequency converting control,easy to adjust the filling speed,automatic count

3.Automatic stop,no bottle no filling.

4.Round turn table for positioning filling,stable and reliable .

5.High precision CAM indexing gage control.It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Applicable specifications 1ml-200mml or customized Production capacity 30-40 Bottle/min or 60-80BPM Filling accuracy ≤±1% Power supply 220V/50Hz Rotating (rolling) cover rate ≥99% Power 2.0 kw Machine net weight 650 kg Dimensions 2440*1700*1800mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

-

Automatic Eye Drop Bottle Filling Plugging Capping Machine

Overview:

This machine is the use of Germany’s advanced technology, the company engineering and technical personnel and other self-developed specifically for the eye-drop liquid or e-liquid filling stoppering capping design, filling parts of the machine adopt peristaltic pump filling, PLC control, filling high precision, easy to adjust the filling range, stopper and cap part adopt manipulator,capping part use magnetic moment capping sealing, sealing beautiful thread, seal firmly. The machine design is reasonable, stable and reliable, easy to operate and maintain, in full compliance with GMP requirements, in addition to this equipment Have bottle no filling function with my company for the washer, washing machine, tunnel sterilization oven, light inspection machine, labeling machine and so on production line linkage.

Please see this video of automatic eye drop filling and capping machine

Working step:

Automatic feeder for bottles—filling—automatic feeder for cap/plug—capping— out put.Features:

1. This filling and capping machine is multi-function monoblock machine with compact design..

2. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

4. The machine is controlled by PLC and touch screen.

5. It applies Peristaltic pump filling system.

6. Flexible for all kinds of capping heads, screw, press, alu. Roll.

7. It is ideal equipment for low-capacity requirement. It can tighten caps automatically.

8. All the parts which touch the material are made of high quality stainless steel, and the surface has been polished, no pollution to the surrounding.

It is suitable for products of liquid such as e-liquid, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Parameters:

Applicable specifications 1ml-200mml or customized Production capacity 30-40 Bottle/min or 60-80BPM Filling accuracy ≤±1% Power supply 220V/50Hz Rotating (rolling) cover rate ≥99% Power 2.0 kw Machine net weight 650 kg Dimensions 2440*1700*1800mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

-

Automatic Eye Drop Mini Bottle Liquid Filling Machine

Overview:

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

Please see this video of automatic eye drop filling and capping machine

Features:

1.All materials in contact with product are of 316L stainless steel and the seals are made of food grade materials.

and other used of 304L stainless steel

2.The filling precision is high.

3.The screw cap can adjustable various cap.

4. Used SIEMENS, Shcnider, Easy to operated

With our core technology and rich experience, we will provide you of filling solution for your requirement. It will simplify your operations.Parameters:

Applied Bottle 10-120ml Productive Capacity 30-100pcs/min Filling Precision 0-1% Qualified stoppering ≥99% Qualified cap putting ≥99% Qualified capping ≥99% Power Supply 380V,50Hz/220V,50Hz (customized) Power 2.5KW Net Weight 600KG Dimension 2100(L)*1200(W)*1850(H)mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Company profile

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

-

Automatic Eye Drop Bottle Filling Stoppering Capping Machine Manufacturer

Overview:

The automatic filling and capping machine is a device designed for bottled liquids . It uses Peristaltic pump filling, positioning type cap feeder, capping, and magnetic moment capping. Using PLC, touch screen control, imported photoelectric detection, high precision, widely used in pharmaceutical, food, chemical, health care products, pesticides and other industries. Made in full compliance with the new GMP requirements.

Working step:

Automatic feeder for bottles—filling—automatic feeder for cap/plug—capping— out put.

feature:

1.Adopt human-computer interface,PLC controller,easy to operate

2.Use frequency converting control,easy to adjust the filling speed,automatic count

3.Automatic stop,no bottle no filling.

4.Round turn table for positioning filling,stable and reliable .

5.High precision CAM indexing gage control.Please see this video of automatic eye drop filling and capping machine

Parameters:

Applied Bottle 10-120ml Productive Capacity 30-100pcs/min Filling Precision 0-1% Qualified stoppering ≥99% Qualified cap putting ≥99% Qualified capping ≥99% Power Supply 380V,50Hz/220V,50Hz (customized) Power 2.5KW Net Weight 600KG Dimension 2100(L)*1200(W)*1850(H)mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Configuration

Breaker: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Button: Schneider

Alarm Light: Schneider

PLC: Siemens

Touch Screen: Simens

Cylinder: Airta

Servo Motor: Schneider

Water Seperator: Airtac

Electromagnetic Valve: Airtac

Visual Inspection: COGNEX

Frequency Converter: Schneider

Detection Photoelectric: SICK

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

.

Q1. What’s the payment terms and trade terms for new customers?

A1: Payment terms: T/T, L/C, D/P, etc.

Trade terms: EXW, FOB, CIF.CFR etc.Q2:What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A2:Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Q3: What’s the Minimum Order Quantity and warranty?

A3: MOQ: 1 set

Warranty: We offer you high quality machines with 12 months guarantee and offer technical support on timeQ4: Do you provide customized service?

A4: Yes, We have professional engineers whom have good experience in this industry for many years, they offer proposals include design machines, complete lines base on your project capacity, configuration requests, and others, make sure fulfill customer needs in market.

Q5.:Are you provide product metal parts and provide us technical guidance?

A5:Wearing parts,for example, motor belt,Disassembly tool(free) are what we could provide.And we can give you technical guidance. -

High Speed Automatic Eye Drop Liquid Filling Machine

Overview:

The screw cap head uses constant torque, automatic slip ping device, will not grind the bottle cap, the bottle will not follow, will not damage the appearance of the bottle. With accurate positioning, no bottles not filling, smooth transmission, simple operation and so on. Tabletops, around the side board are imported 304 high-quality stainless steel, with the liquid contact part of 316L stainless steel, the whole machine in line with GMP requirements. The production line transmission is mechanical transmission, transmission is accurate, smooth, gas-free pollution and the various institutions without error and other phenomena. When working, the noise is low, the loss is low, the work is stable, the output is stable, especially suitable for batch production.

Please see this video of automatic eye drop filling and capping machine

Features:

1.All materials in contact with product are of 316L stainless steel and the seals are made of food grade materials.

and other used of 304L stainless steel

2.The filling precision is high.

3.The screw cap can adjustable various cap.

4. Used SIEMENS, Shcnider, Easy to operated

With our core technology and rich experience, we will provide you of filling solution for your requirement. It will simplify your operations.Parameters:

Applied Bottle 10-120ml Productive Capacity 30-100pcs/min Filling Precision 0-1% Qualified stoppering ≥99% Qualified cap putting ≥99% Qualified capping ≥99% Power Supply 380V,50Hz/220V,50Hz (customized) Power 2.5KW Net Weight 600KG Dimension 2100(L)*1200(W)*1850(H)mm Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.

Adopt Peristaltic pump:

It’s suitable for fluid filling.Capping part:

Put the inner plug-put the cap-screw the caps.Adopt magnetic torque screwing capping:

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Configuration

Breaker: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Button: Schneider

Alarm Light: Schneider

PLC: Siemens

Touch Screen: Simens

Cylinder: Airta

Servo Motor: Schneider

Water Seperator: Airtac

Electromagnetic Valve: Airtac

Visual Inspection: COGNEX

Frequency Converter: Schneider

Detection Photoelectric: SICK

Company profile

Shanghai Ipanda Intelligent Machinery Co., Ltd. is a comprehensive enterprise specialized in the design, manufacture, R&D, trade of filling equipment and packaging equipment.Our R&D and manufacture team has more than 10 years of experience in the filling industry. Our factory covers an area of 5000 square meters,now it has a second factory as a showroom, which includes a complete set of production lines for packaging equipment in the daily chemical, pharmaceutical, petrochemical, and food industries.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debuggingFAQ

Q1. Are you manufactory?

A1: Yes, We are manufactory of filling-capping-labeling-bottle washing machine, and complete line, Our factory is nearby Shanghai, located in Xuzhou, Jiangsu Province.Q2. What’s the payment terms and trade terms for new customers?

A2: Payment terms: T/T, L/C, D/P, etc.

Trade terms: EXW, FOB, CIF.Q3: What’s the Minimum Order Quantity and warranty?

A3: MOQ: 1 set

Warranty: We offer you high quality machines with 12 months guarantee and offer technical support on timeQ4: Do you provide customized service?

A4: Yes, We have professional engineers whom have good experience in this industry for many years, they offer proposals include design machines, complete lines base on your project capacity, configuration requests, and others, make sure fulfill customer needs in market. -

Automatic Small Eye Drops Bottle Liquid Filling Capping Machine

Overview:

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

Please see this video of automatic eye drop filling and capping machine

Features:

1. This filling and capping machine is multi-function monoblock machine with compact design..

2. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

4. The machine is controlled by PLC and touch screen.

5. It applies Peristaltic pump filling system.

6. Flexible for all kinds of capping heads, screw, press, alu. Roll.

7. It is ideal equipment for low-capacity requirement. It can tighten caps automatically.

8. All the parts which touch the material are made of high quality stainless steel, and the surface has been polished, no pollution to the surrounding.

Parameters:

Applied Bottle 10-120ml Productive Capacity 30-100pcs/min Filling Precision 0-1% Qualified stoppering ≥99% Qualified cap putting ≥99% Qualified capping ≥99% Power Supply 380V,50Hz/220V,50Hz (customized) Power 2.5KW Net Weight 600KG Dimension 2100(L)*1200(W)*1850(H)mm -

Customize Accepted Automatic 4 Nozzles Eliquid and Eye Drop Filling Machine

Overview:

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

Please see this video of automatic eye drop filling and capping machine

Features:

1. This filling and capping machine is multi-function monoblock machine with compact design..

2. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

4. The machine is controlled by PLC and touch screen.

5. It applies Peristaltic pump filling system.

6. Flexible for all kinds of capping heads, screw, press, alu. Roll.

7. It is ideal equipment for low-capacity requirement. It can tighten caps automatically.

8. All the parts which touch the material are made of high quality stainless steel, and the surface has been polished, no pollution to the surrounding.

Parameters:

Applied Bottle 10-120ml Productive Capacity 30-100pcs/min Filling Precision 0-1% Qualified stoppering ≥99% Qualified cap putting ≥99% Qualified capping ≥99% Power Supply 380V,50Hz/220V,50Hz (customized) Power 2.5KW Net Weight 600KG Dimension 2100(L)*1200(W)*1850(H)mm