-

China manufacturer high quality automatic honey filling machine and bee honey filling machine

This machine is an automatic metering and bottling production line for liquid/paste materials and has the functions of automatic metering and bottling.Upon user’s request it can be equipped with the functions of weight checking, metal detection, sealing, screw capping, etc.All the sections in contact with the material are made of stainless steel, the whole machine is controlled by PLC and features high precision and quick speed.There are 2heads/4heads/6heads/8heads/12heads for choosing accoridng to customer’s capacity

-

Automatic Engine Oil Filling Machine Lube Oil Rotary Oil Filling Machine

The oil filling production line produced by Planet Machinery adopts servo control piston filling technology, high precision, high speed stable performance, fast dose adjustment features.

The oil filling machine is suitable for edible oil, olive oil, peanut oil, corn oil, vegetable oil, etc.

The design and production of this oil filling equipment is in accordance with GMP standard requirements. Easily dismantle, clean and maintain. The parts which contact filling products are made of high quality stainless steel. The oil filling machine is safe, environmental, sanitary, adapting to various kinds of working places.

This video is for your reference,we will customized according to clients requirements

-

Automatic Oral Liquid Syrup Chemical Liquid Filling Machine

This machine is the main filling and sealing machine in liquid production line, in line with GMP requirements. It is made of high quality 304 stainless steel material, and the part of contacting liquid is made of 316 stainless steel. Suitable for filling, capping, capping (rolling/capping) of all kinds of bottled liquid. The machine combines filling and sealing into one. Advanced design, compact structure. The replacement is very convenient, and the combination with other equipment can achieve assembly line production.

This video is automatic syrup filling and capping machine,We can supply all kinds of filling machine

-

Automatic monoblock liquid syrup filling line pure maple syrup filling machine

The piston filling machine can be connected with filling line,and mainly suitable for viscosity liquids.It adopts integrated design, using high quality electrical components such as PLC, a photoelectric switch, touch screen and high quality stainless steel, plastic parts. This machine is good quality. System operation, convenient adjustment, friendly man machine interface, the use of advanced automatic control technology, in order to achieve a high precision liquid filling.

This video is automatic syrup filling and capping machine,We can supply all kinds of filling machine

-

Full automatic filling machine line for honey

The machine is suitable for the quantitative filling of various kinds of sauces such as tomato sauce, chili sauce, water jam, high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

-

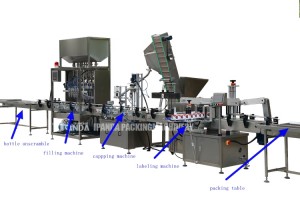

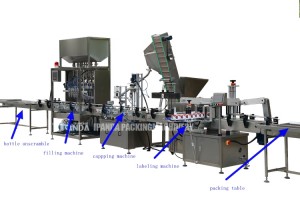

China Factory Manufacture Filling Capping Labeling Machine for Chemical Liquid

Automatic liquid bottle filling capping & labeling machine controlled by pneumatic and electric. For filling, it through the cylinder’s movement of forward and backward to make the piston which is located in the cylinder do reciprocating movement. Mainly use in filling low viscosity or liquid products, like lotion, liquid laundry detergent, fabric softener, shampoo, hand wash liquid soap, bath shower, dish washing liquid, etc.

Filling volume from 50ml to 5000ml optional. Also can be customized

Filling nozzles can be customized with 4 heads, 6 heads, 8 heads, 10 heads and 12 heads anti-drop type, different size as your request.

-

Automatic Fruit Jam Filling Capping Labeling Machine for Complete Packaging

Accurate measurement: The servo control system to ensure that the total can reach a constant position of the piston.

Variable speed filling: In the filling process, when close to the target filling volume to achieve a slow speed can be applied when filling, to prevent fluid overflow bottle pollution.

Adjustment convenient: Replacement of filling in the specifications only in the touch screen you can change the parameters, and all the filling for the first time changes in place. -

Automatic 8 head piston filler/bottle filling machines olive oil cooking oil

The oil filling production line produced by Planet Machinery adopts servo control piston filling technology, high precision, high speed stable performance, fast dose adjustment features.

The oil filling machine is suitable for edible oil, olive oil, peanut oil, corn oil, vegetable oil, etc.

The design and production of this oil filling equipment is in accordance with GMP standard requirements. Easily dismantle, clean and maintain. The parts which contact filling products are made of high quality stainless steel. The oil filling machine is safe, environmental, sanitary, adapting to various kinds of working places.

This video is for your reference,we will customized according to clients requirements

-

High performance tomato paste jam filling machine capping machine

This jam filling machine adopts plunger pump filling, Equipped with PLC and touch

screen, easy to operate. bottle filling machine main pneumatic parts and the electronics are famous brands from Japan or German. bottle filling machine price body and the parts contacting with the product is stainless steel, clean and sanitary comply with GMP standard. The filling volume and speed can be adjusted easily, and filling nozzles could be changed according to actual needs. This filling line can be used to fill various liquid products of medicines, foods, drinks, chemicals, detergents, pesticides, etc.Configuration List

Breaker: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Button: Schneider

Alarm Light: Schneider

PLC: Siemens

Touch Screen: Simens

Cylinder: Airtac

Servo Motor: Schneider

Water Seperator: Airtac

Electromagnetic Valve: Airtac

Visual Inspection: COGNEX

Frequency Converter: Schneider

Detection Photoelectric: SICK

-

Cost Effective Automatic Honey Machine Tomato Paste Jam Sauce Butter Filling Sealing Packing Machine

Accurate measurement: The servo control system to ensure that the total can reach a constant position of the piston. Variable speed filling: In the filling process, when close to the target filling volume to achieve a slow speed can be applied when filling, to prevent fluid overflow bottle pollution.Adjustment convenient: Replacement of filling in the specifications only in the touch screen you can change the parameters, and all the filling for the first time changes in place.

-

Hot selling full automatic hot paste and pepper sauce filling capping machine

This jam filling machine adopts plunger pump filling, Equipped with PLC and touch

screen, easy to operate. bottle filling machine main pneumatic parts and the electronics are famous brands from Japan or German. bottle filling machine price body and the parts contacting with the product is stainless steel, clean and sanitary comply with GMP standard. The filling volume and speed can be adjusted easily, and filling nozzles could be changed according to actual needs. This filling line can be used to fill various liquid products of medicines, foods, drinks, chemicals, detergents, pesticides, etc.Configuration List

Breaker: Schneider

Switching Power Supply: Schneider

AC Contactor: Schneider

Button: Schneider

Alarm Light: Schneider

PLC: Siemens

Touch Screen: Simens

Cylinder: Airtac

Servo Motor: Schneider

Water Seperator: Airtac

Electromagnetic Valve: Airtac

Visual Inspection: COGNEX

Frequency Converter: Schneider

Detection Photoelectric: SICK

-

gasoline motor oil filling machine Car Engine oil motor oil filling packing machine line

The oil filling production line produced by Planet Machinery adopts servo control piston filling technology, high precision, high speed stable performance, fast dose adjustment features.

The oil filling machine is suitable for edible oil, olive oil, peanut oil, corn oil, vegetable oil, etc.

The design and production of this oil filling equipment is in accordance with GMP standard requirements. Easily dismantle, clean and maintain. The parts which contact filling products are made of high quality stainless steel. The oil filling machine is safe, environmental, sanitary, adapting to various kinds of working places.

This video is for your reference,we will customized according to clients requirements