-

Factory sale Liquid Hand Wash Liquid Filler Hand Soap Sanitizer filling machine

This machine is applied for viscosity and paste filling similar like cream, shampoo, liquid soap, lubricant, engine oil products. It is able to integrate to capping machine and labeling machine in bottling line, fully complete and intelligence control advantage.

-

Full automatic filling machine for soap/shampoo/hand sanitizer

This machine have been widely used in manufacturing,chemical,food,beverage and other industries.It is specially designed for high viscosity liquid Easily controlled by computer (PLC), touch screen control panel . It is characterized by its totally close from ,submerged filling ,high measurement accuracy , compact and perfect feature ,liquid cylinder and conduits disassemble and clean . It may also suited various figure containers . We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement

-

Automatic Customized Heads High Viscosity Liquid Detergent Filling Machine Line

This machine is applied for viscosity and paste filling similar like cream, shampoo, liquid soap, lubricant, engine oil products. It is able to integrate to capping machine and labeling machine in bottling line, fully complete and intelligence control advantage.

-

Automatic hotel shampoo bottle cream jar lotion filling machine

This is our newly developed filling machine . This is a inline piston filling machine for cream and liquid ..It adopts PLC and touch screen control panel for control material . It is characterized by accurate measuring ,advanced structure ,stable operating ,low noise ,large adjusting range ,fast filling speed . It is also suitable for the filling of easy volatilization ,easy bubbly liquid strong corrosive liquid for rubber ,plastic,and high viscosity ,liquid ,semi-liquid . Operators adjust and meter figure in the touch screen control panel , also can adjust metering of each filling head . The external surface of this machine is made of excellent stainless steel . Good appearance , applied to GMP standard .

If you have any intersted about our products,please check this video

-

Automatic diswashing filling machine new condition detergent filler

This machine is applied for viscosity and paste filling similar like cream, shampoo, liquid soap, lubricant, engine oil products. It is able to integrate to capping machine and labeling machine in bottling line, fully complete and intelligence control advantage.

-

Automatic Shampoo Bottle Filling and Capping Machine

This machine have been widely used in manufacturing, chemical, food, beverage and other industries. It is especially designed for high viscosity liquid Easily controlled by computer (PLC), touch screen control panel. It is characterized by its totally close from, submerged filling, high measurement accuracy, compact and perfect feature, liquid cylinder and conduits disassemble and clean. It may also suited various figure containers. We utilize high-quality stainless steel frames, international famous brand electrical components, the machine is applied to GMP standard requirement.

If you have any intersted about our products,please check this video

-

Automatic 4 heads or 6 heads customize glass jar honey filling and capping machine

Overview:

This machine is specially made for filling all kinds of viscousity materials in food industry, such as chocolate paste, peanut butter, tomato sauce/jam/ketchup, honey, yogurt etc. The machine adopts piston pump for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision. The whole machine is made of high quality stainless steel.

Features:

1> Different filling volume can be set on HMI directly,

2> Fast to adjust for different bottle within 10-20 min.;

3> Servo motor driven, High Filling Accuracy within ±0.5%.

(depends on the material and filling volume).4> CE , ISO and SGS approved and production comply with GMP standard;

5> Hygienic tri-clamps connection , easy to remove and clean;

6> CIP cleaning function available;

7> Buffer tanks with level control system;

8> Mature alarm system for safe operation.

9> Adopts international first-class electric and pneumatic configuration;

Mistubishi / Siemens / Delta PLC and touch screen,

Schneider/ omron low Voltage electricals, and Autonics sensor.Adopt SS304 or SUS316L filling nozzles

Accurate measurement,no splashing ,no overflow

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Parameters

Filling material

Jam,Peanut butter,Honey,Meat Paste,Ketchup,Tomato Paste

Filling nozzle

1/2/4/6/8 can be adjusted by customers

Filling volume

50ml-3000ml customized

Filling precision

±0.5%

Filling speed

1000-2000 bottles/hour can be adjusted by customers

Single machine noise

≤50dB

Control

Frequency Control

Warranty

PLC, Touch screen

-

Automatic Honey Filler Glass Jar Honey Filling Machine

Overview:

The filling machine is specially made for liquid with paste such as tomato paste, honey, jam, gel, peanut butter, oil etc. The automatic honey filling machine adopts Japanese Mitsubishi PLC program system to control. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision.

Features:

1. The flow control devices of each filling head are independent of each other, precision adjustment is very convenient.

2. The material of the machine material contact part can use the food grade material according to the products feature, in line with the GMP standard.

3. With regular filling, no bottle no filling, filling quantity/production counting function etc features.

4. Convenient maintenance,no need any special tools.

5. Using drip tight filling head,no leaking.

6. Photoelectric Sensor, Mechatronics Filling Adjustment System,Material Level Control Feeding System

7.Stainless Steel Frame,Plexiglass as Security Cover

8. Control System: PLC/Electronic-Pneumatic Controlled

9. Capaity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.Adopt SS304 or SUS316L filling nozzles

Accurate measurement,no splashing ,no overflow

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Parameters

Filling material

Jam,Peanut butter,Honey,Meat Paste,Ketchup,Tomato Paste

Filling nozzle

1/2/4/6/8 can be adjusted by customers

Filling volume

50ml-3000ml customized

Filling precision

±0.5%

Filling speed

1000-2000 bottles/hour can be adjusted by customers

Single machine noise

≤50dB

Control

Frequency Control

Warranty

PLC, Touch screen

-

Paste/Sauce Filling Machine

The machine is suitable for the quantitative filling of various kinds of sauces such as tomato sauce, chili sauce, water jam, high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

-

CE Approval Automatic Honey Jam Jar Viscous Liquids Filling Machine

The machine is suitable for the quantitative filling of various kinds of sauces such as tomato sauce, chili sauce, water jam, high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

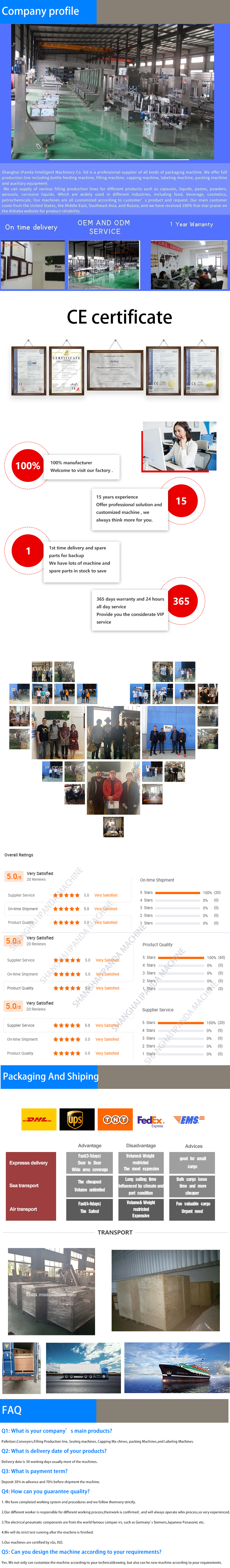

Why us

Our quality products are consisting of Superior Design and Latest Technology with High Graded Raw Materials. These are acknowledged for their Efficiency and Durability. The organization is equipped with all the required facilities to manufacture quality products that are at par with changing market trends. -

Automatic 6 nozzles cooking bottle oil filling capping and labeling machine

The oil filling production line produced by Planet Machinery adopts servo control piston filling technology, high precision, high speed stable performance, fast dose adjustment features.

The oil filling machine is suitable for edible oil, olive oil, peanut oil, corn oil, vegetable oil, etc.

The design and production of this oil filling equipment is in accordance with GMP standard requirements. Easily dismantle, clean and maintain. The parts which contact filling products are made of high quality stainless steel. The oil filling machine is safe, environmental, sanitary, adapting to various kinds of working places.

This video is for your reference,we will customized according to clients requirements

-

Industrial machinery automatic engine gear oil production line auto piston type filling machine

This machine is suitable for various viscous and non visvous and corrosive liquid,widely used in plant oil,chemical liquid,daily chemical industry quantitative small packing filling,linear filling,electromechanical integration control,replacement of species is quite convenient,unique design,superior performance,other in conformity with the concept of international machinery and equipment.

This video is for your reference,we will customized according to clients requirements