One of Hottest for Granule Packaging Machine - Automatic Chemical Liquid Filling Production Line – Ipanda

One of Hottest for Granule Packaging Machine - Automatic Chemical Liquid Filling Production Line – Ipanda Detail:

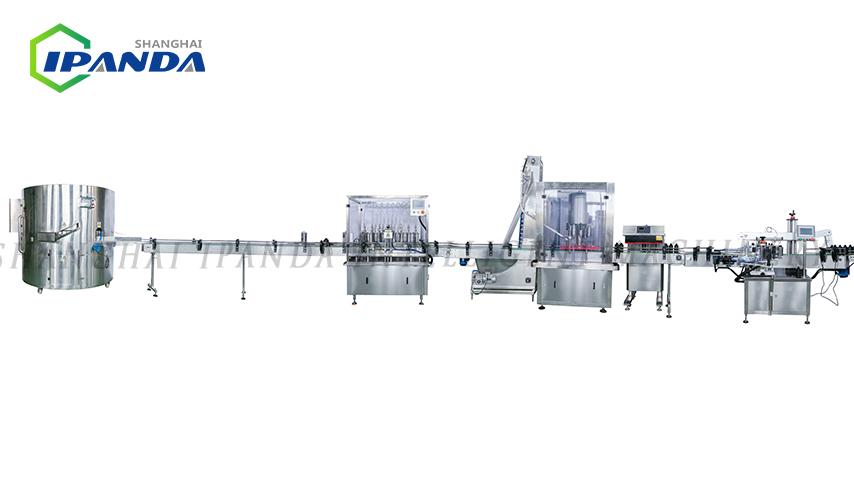

Product Display

Overview

Automatic liquid bottle filling capping & labeling machine controlled by pneumatic and electric.

For filling, it through the cylinder’s movement of forward and backward to make the piston which is located in the cylinder do reciprocating movement.

Mainly use in filling low viscosity or liquid products, like lotion, liquid laundry detergent, fabric softener, shampoo, hand wash liquid soap, bath shower, dish washing liquid, etc.

Filling volume from 50ml to 5000ml optional. Also can be customized

Filling nozzles can be customized with 4 heads, 6 heads, 8 heads, 10 heads and 12 heads anti-drop type, different size as your request.

Automatic bottle uncrambler— Filling machine— Capping machine—Aluminum foil sealing machine — Labeling machine

Parameters

|

Machine |

Item |

Specification |

|

Bottle uncrambler |

Function | Organize and collect the bottles |

| Bottle Application | Pet bottle,Plastic bottle | |

| Application | Beach,Liquid soap, shampoo, lotion, cream, detergent etc. | |

| Filling Volume | 50-500ml, 100-1000ml, 500-5000ml can be customized | |

| Filling Speed | 1800-2400BPH (customized) | |

| Filling Nozzle | Six head(customized) | |

|

Capping Machine |

Application | Screw caps, pump heads etc. |

| Applicable cap diameter | 20~55mm (customized) | |

| Capping Speed | 1200-3000BPH (customized) | |

| Driven Type | Electric | |

| Speed Control | Interval control, the speed is adjustable. | |

|

Aluminum foil sealing machine |

Bottle height | 35~250mm |

| Bottle diameters | Φ20~φ80mm | |

| Application | Round bottles,flat bottle square bottle | |

| Applicable Label Height | 20-100mm (customized) | |

| Label roll inner diameter | Φ76.2mm (customized) | |

|

Labeling machine |

Application | Round bottles,flat bottle square bottle |

| Applicable Label Height | 20-100mm (customized) | |

| Label roll inner diameter | Φ76.2mm (customized) | |

| Max. label roll outer diameter | φ350mm (customized) | |

| Labeling Speed | 2000-3000BPH |

Features

1. The use of the world’s famous brand electrical and pneumatic components, low failure rate, stable and reliable performance,long service life;

2. Contact with material are made of stainless steel, tear open outfit is simple, easy to clean, accord with food hygiene requirements;

3. The filling volume and filling speed adjustment is simple, there is the function of no bottle no filling, liquid level automatic control feeding, beautiful appearance;

4. Do not need to change parts, replacement of different specifications of the bottle shape can be changed very fast, high applicability;

5. Filling the mouth with drip tight device, ensure filling without drawing, no dripping.

The Machine Details

Bottle Unscrambler Part

The main motor speed reducer applies torque limit mechanism to avoid harming the machine when trouble happens.

Filling part:

ANTI-DROP Filling Nozzles

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Capping machine and aluminum foil sealing machine

Modular manufacturing,easy to assemble or disassemble,and easy to maintain.Screw the cap at high speed and efficiency is high,Safe and reliable.

Standing Style Incuction Foil sealing machine is widely applied for Fuel additive, medicine bottle, sport bottle, honey jar, medicine bottle ,yogurt bottle, chili sauce and so on.

Capping part

Labeling Part

This double side labeling machine model is perfectly suitable for applying labels on both sides of bottles and containers of various shapes and sizes

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for One of Hottest for Granule Packaging Machine - Automatic Chemical Liquid Filling Production Line – Ipanda , The product will supply to all over the world, such as: Barbados, Washington, Sevilla, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!