OEM/ODM Supplier Powder Packing Machine - Piston Type Daily Chemical Laundry Detergent Shampoo Bottle Filling Machine – Ipanda

OEM/ODM Supplier Powder Packing Machine - Piston Type Daily Chemical Laundry Detergent Shampoo Bottle Filling Machine – Ipanda Detail:

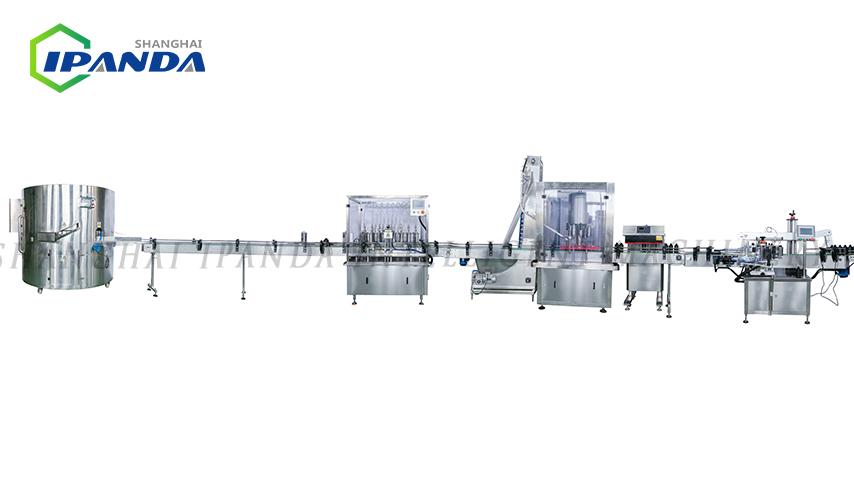

Product Display

Overview

High Viscosity Liquid Filling Machine is the new-generation improved volumetric filling machine which is Suitable for material:viscous liquid

The whole machine uses the in-line structure and it is driven by the servo motor. Volumetric filling principle can realize the high precision of filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjustment easier. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.

Automatic bottle uncrambler— Filling machine— Capping machine—Aluminum foil sealing machine — Labeling machine

Parameters

| Items# | Description | Details |

| 01 | Number of filling heads: | 2,4,6,8 Customized |

| 02 | Filling range: | 1000-1500ML customized |

| 03 | Voltage: | 220V/380V 50HZ |

| 04 | Power: | 1.5 KW |

| 05 | Weighing error: | ≤0.2% |

| 06 | Production capacity: | 1500BPH customized |

| 07 | Dimension(mm): | 2000*1500*2200mm |

| 08 | Weight: | 900KG |

Features

1.Supported by PLC software, the servo motor, servo driver, and volume adjustment only need to set the target volume on the touch screen, and the equipment can automatically increase or decrease to reach the target volume. Color touch display operation, monitoring and other functions.

2.Wide application range and easy adjustment

3.It is suitable for filling most bottle types (especially shaped bottles), and it is convenient to adjust the volume.

4.It adopts anti-drip and wire-drawing filling head, anti-high foaming product filling and lifting system, positioning system to ensure bottle mouth positioning and liquid level control system.

The Machine Details

Filling part:

ANTI-DROP Filling Nozzles

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Capping machine and aluminum foil sealing machine

Modular manufacturing,easy to assemble or disassemble,and easy to maintain.Screw the cap at high speed and efficiency is high,Safe and reliable.

Standing Style Incuction Foil sealing machine is widely applied for Fuel additive, medicine bottle, sport bottle, honey jar, medicine bottle ,yogurt bottle, chili sauce and so on.

Capping part

It adopts variable frequency speed regulation, mechanical capping mechanism with complete functions;

The appearance structure of the whole machine is 304 stainless steel, which has good performance, easy operation and beautiful appearance;

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for OEM/ODM Supplier Powder Packing Machine - Piston Type Daily Chemical Laundry Detergent Shampoo Bottle Filling Machine – Ipanda , The product will supply to all over the world, such as: Dubai, Latvia, Florida, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.