OEM/ODM Manufacturer Crown Capping Machine - Automatic Hand Sanitizer Face Cream Cosmetic Bottling Plant Shampoo washing Liquid Soap Detergent Bottle Filling Machine – Ipanda

OEM/ODM Manufacturer Crown Capping Machine - Automatic Hand Sanitizer Face Cream Cosmetic Bottling Plant Shampoo washing Liquid Soap Detergent Bottle Filling Machine – Ipanda Detail:

Product Display

Overview

This high viscosity viscous liquid volumetric filling sealing and capping machine piston filling machine ,widely used in Daily chemical industry, Cosmetic, food industry ,high viscosity materials, shampoo, hair condition cream, hand cream dish washing liquid and so on, the effect is obvious. Filling method can customize according to customer’s different material , if customer’s material is low viscosity material , suggest use gravity flow filling machine, if customer’s material is high viscosity material , suggest use piston filling machine If customer’s material have many foam, also can customize vacuum filling and diving filling , If customer’s haven’t fluidity, easy to precipitation , can customize mixer and heating hopper above filling machine.

Parameter

| Name | Liquid Filling Machine |

| Filling nozzle number | 2/4/6/8/12(can be customized) |

| Filling volume | 100-1000ml(can be customized) |

| Filling speed | 15-100bottles/min |

| Filling accuracy | 0 to 1% |

| Total power | 3.2KW |

| Power supply | 1ph .220v 50/60Hz |

| Machine size | L2500*W1500*H1800mm(customized) |

| Net weight | 600KG(customized) |

Features

1. Automactic liquid filling machine,Small size, reasonable design, easy operation, stable performance, low failure rate;

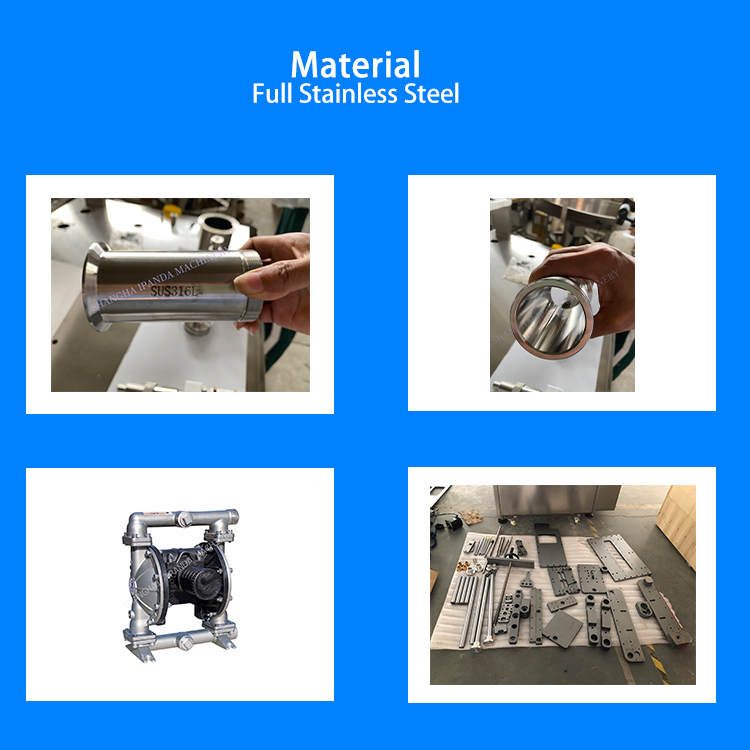

2. The whole machine is made of high-quality stainless steel. The 304/316L stainless steel material is used in contact with the material to meet the GMP hygienic requirements.

3. Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

4. There are filling volume adjustment handles, filling speed adjustment knobs, which can adjust the filling volume and filling speed arbitrarily; the filling precision is high;

5. According to the requirements of the environment, it can be changed to a full-air-explosion-proof type. It is completely de-energized and safer.

6. According to customer needs, customize the production of 4 heads, 6 heads, 8 heads and 12 heads.

7. Plastic bottles and glass bottles are customized according to customer requirements.

Application

50ML-5L plastic bottles, glass bottles, round bottles, square bottles, hammer bottles are applicable

Hand sanitizer, shower gel, shampoo, disinfectant and other liquids, with corrosive liquids, paste are applicable.

The Machine Details

Filling Nozzles

2/4/6/8/10 Customizable no-drop filling nozzles. Different sizes to fit different bottles, easy to be assembled.All the material contact part is made of stainless steel 316L.

Various Filling Range

10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml. With adjustable speed conveyor belt, and high strength stainless steel frame, firm and wear-used.

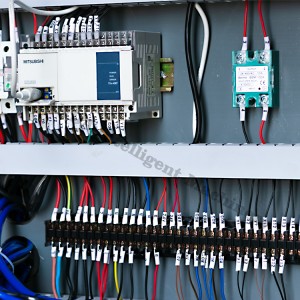

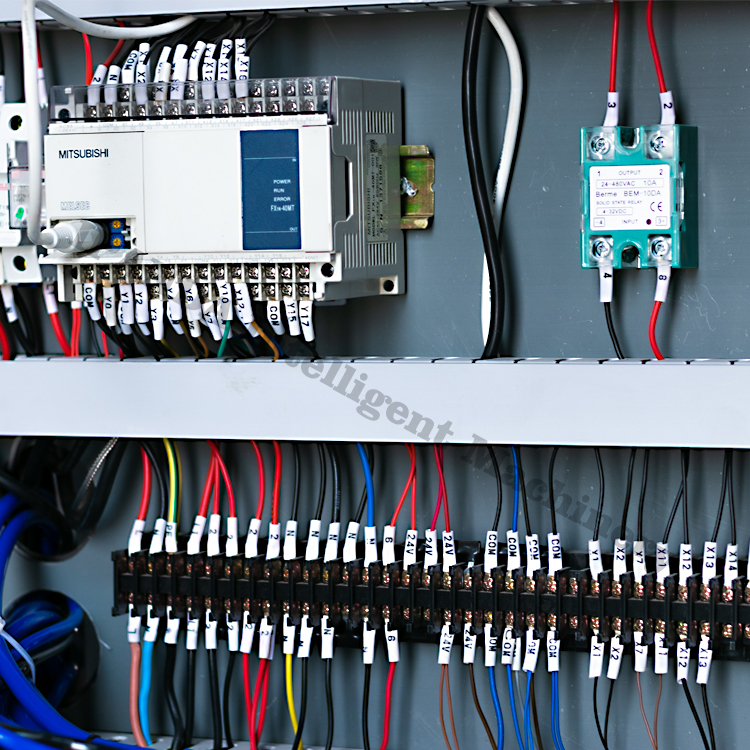

PLC Control System

Imported brands for PLC touch screen control system, high class appearance, easier and faster for operation. filling

We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement.

Machine configuration

|

Frame |

SUS304 Stainless steel |

|

Parts in contact with liquid |

SUS316L Stainless steel |

|

Electrical parts |

|

|

Pneumatic part |

|

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for OEM/ODM Manufacturer Crown Capping Machine - Automatic Hand Sanitizer Face Cream Cosmetic Bottling Plant Shampoo washing Liquid Soap Detergent Bottle Filling Machine – Ipanda , The product will supply to all over the world, such as: Ukraine, Macedonia, Southampton, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.