OEM/ODM Factory E-Liquid Filling Machine - Automatic sauce jam mayonnaise filling machine production line – Ipanda

OEM/ODM Factory E-Liquid Filling Machine - Automatic sauce jam mayonnaise filling machine production line – Ipanda Detail:

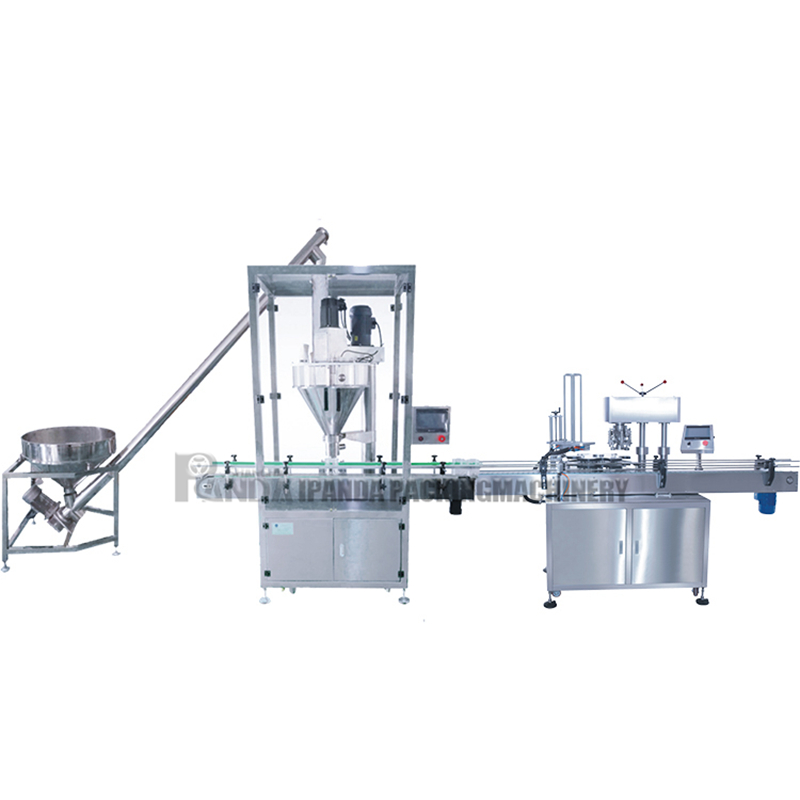

Product Display

Overview

This machine is suitable for filling aqueous solutions and cream products, particularly for high viscosity materials (such as cosmetics, seed coating agent, motor lubricating oil, suspending agent etc.) the effect is obvious.Using PLC programmable control, with touch screen and man-machine interface system; automatic bottle feeding, automatic filling, automatic send bottle out; driven by a servo motor, double screw drive,control the movement of the piston rod to ensure the stability of the filling, filling precision higher.

Parameter

|

Filling material |

Jam,Peanut butter,Honey,Meat Paste,Ketchup,Tomato Paste |

|

Filling nozzle |

1/2/4/6/8 can be adjusted by customers |

|

Filling volume |

50ml-3000ml customized |

|

Filling precision |

±0.5% |

|

Filling speed |

1000-2000 bottles/hour can be adjusted by customers |

|

Single machine noise |

≤50dB |

|

Control |

Frequency Control |

|

Warranty |

PLC, Touch screen |

Features

Feeding pipe

Use heat-resistant pipes to transport materials from the tank to the filling head for filling, which is easy to clean and easy to replace.

Heat preservation

The material itself has a very high temperature. When it comes into contact with the filling machine, the temperature in the tank will change with time. At this time, a heat preservation device can be added to keep the temperature within a certain range

Ball valve

It is used to control the filling open and close, when the push material volume reach filling volume, the ball will open automatically and begin filling.

Servo Motor

Using the servo motor drive, double ball screw drive, to ensure the stability of the piston movement, high precision, from the surface to achieve accurate filling.

Piston pump cylinder

control filling volume and control open and

off filling. The volume of this piston cylinder is according to your filling volume to

customize.ensure the filling accuracy, through Piston pump rod to push in the cylinder.

Application

Food (olive oil, sesame paste, sauce, tomato paste, chili sauce,butter,honey etc.) Beverage( juice, concentrated juice). Cosmetics (cream, lotion,shampoo, shower gel etc) Daily chemical (dishwashing, toothpaste, shoe polish, moisturizer, lipstick, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricants, and plaster pastes for special industries The equipment is ideal for filling high-viscosity liquids, pastes, thick sauces, and liquids. we customize machine for different size and shape of bottles.both glass and plastic are OK.

The Machine Details

Adopt SS304 or SUS316L filling nozzles

Anti-drop filling nozzle, piston cylinder control filling (Servo motor contro), filling stable and filling accuracy higher.

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of OEM/ODM Factory E-Liquid Filling Machine - Automatic sauce jam mayonnaise filling machine production line – Ipanda , The product will supply to all over the world, such as: Bangladesh, Estonia, Hyderabad, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.