Nasal Spray Bottling and Filling Machine With PLC Control

This machine is mainly available to fill Oil, Eye-drop, Cosmetics oil, E-liquid, hand sanitizer, perfume, gel into various round and flat Glass bottles. High precision cam provides a regular plate to position, cork and cap; accelerating cam makes capping heads going up and down; constant turning arm screws caps; piston measures filling volume; and touch screen controls all action. No bottle no filling and no capping. The machine enjoys high position accuracy, stable driving, precise dosage, and simple operation and also protects bottle caps. Servo motor control peristaltic pump filling for less tham 50ml bottle filling,

Specification:

| No. | Item | Specs |

| 1 | Application | 5ml-250ml |

| 2 | Power | 1.5Kw / 220V 50Hz |

| 3 | Accuracy | ±0.5~1% |

| 4 | Air pressure | 0.4-0.6Mpa |

| 5 | Air consumption | 25-35L/min |

| 6 | Gross Weight | 550Kg |

| 7 | Dimension | 2080×960×1480(mm) |

| 8 | Capacity | 30-50 bottle/ min 50-100 bottles/min |

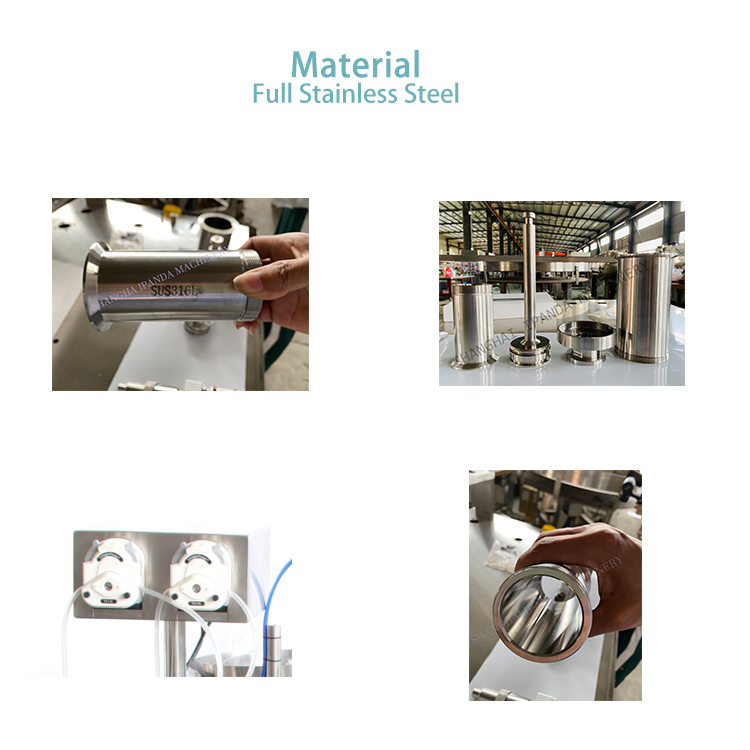

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

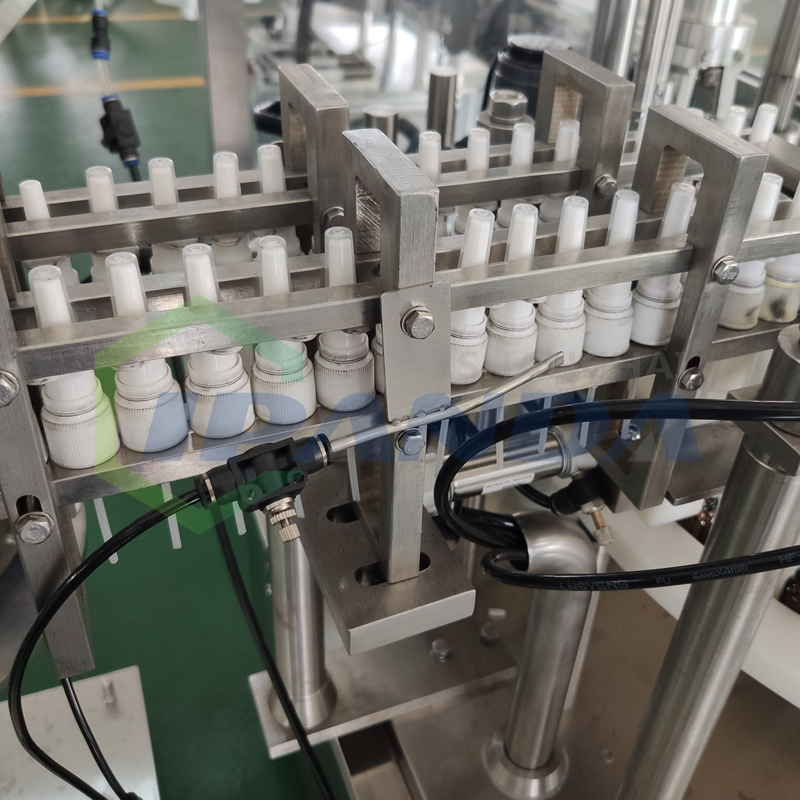

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

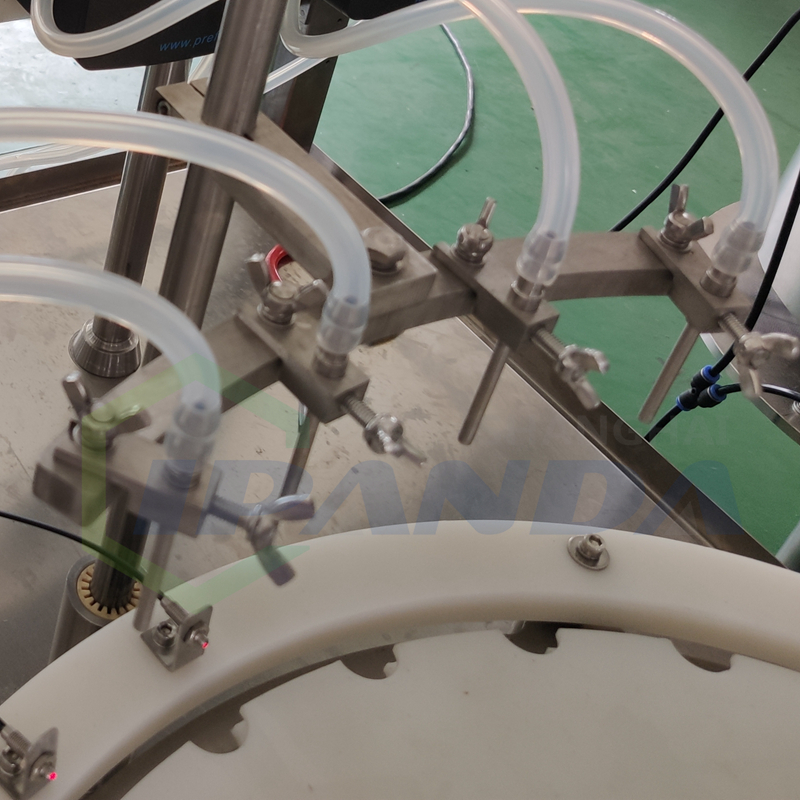

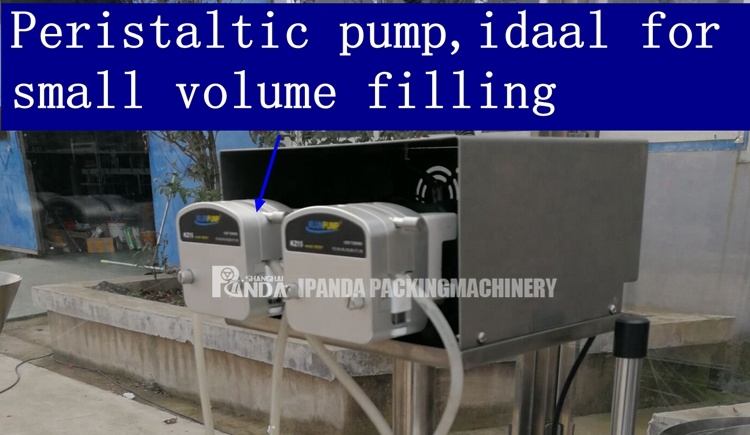

The filling heads can be customized based on customer's requirements and also filling system will be used that decides on the filliing material. According to the viscosity of customer's material to choose the peristalic pump filling or piston pump filling. We can also provide anti-drip design.

2) The multi roller structure of our peristaltic pump further improves the stability and non impact of filling and makes the liquid filling stable and not easy to blister. It is especially suitable for filling the liquid with high requirement.

The vibrating plate is for the inner cap and outer cap loading, it is will customize based on bottle cap, if it is only cap, just need one set of vibrating plate. It will be used to sort of different kinds of caps and send bottle into loading cap guider automatically one by one.

The cap head is in high quality and stronger, so it can screw tightly and won't damage the cap.

The bottle is fixed on the mould of disk and then it is screwed by the capping head.

Drop cap inset station that put dropper aumatically is used for dropper bottle

Dould capping station will be used for inner plug and outside cap.

One plugging station, catch plug head will suck plug and insert it into bottle mouth ,capping station will suck outside cap put into bottle mouth too.