Multi Head Peristaltic Pump Volumetric Perfume Spray Filling Machines

This machine is auto negative pressure vacuum filling, auto bottle detecting( no bottle no filling )

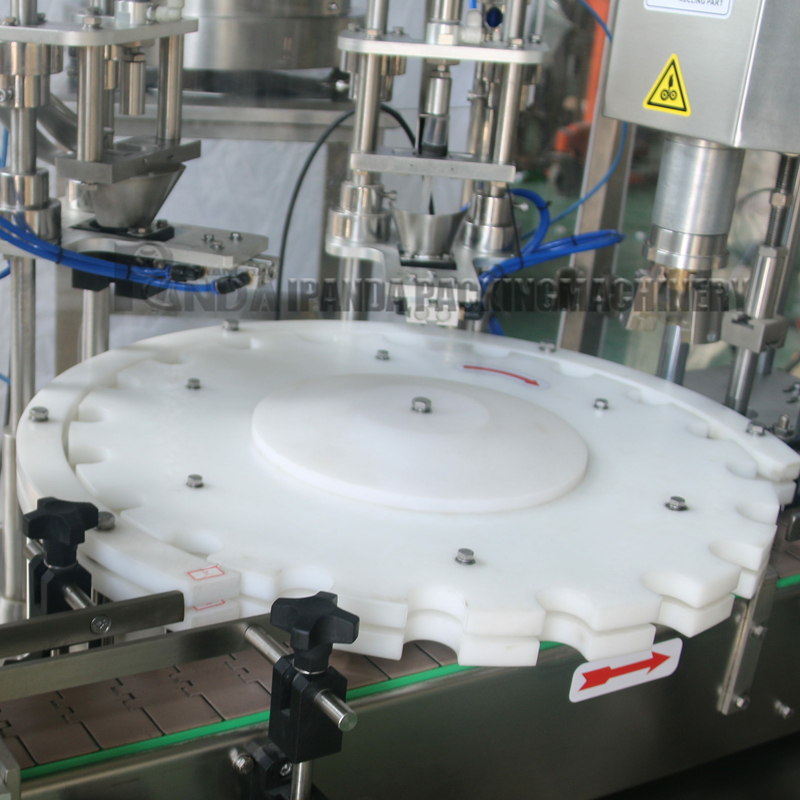

Auto dropping of crimp pump cap, circulation of spray bottles’ die set, It is wide adaptability which can meet to requirements of different dimension and filling volume of containers.

This filling machine can be divided into automatic bottles feeding (Also can use choose manual load bottle)automatic filling, automatic pump cap capping head, pre-capping head for regulate and tighten up pump cap head and automatic capping etc.

| Applied Bottle | 5-200ml customized |

| Productive Capacity | 30-100pcs/min |

| Filling Precision | 0-1% |

| Qualified stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V,50Hz/220V,50Hz (customized) |

| Power | 2.5KW |

| Net Weight | 600KG |

| Dimension | 2100(L)*1200(W)*1850(H)mm |

1)Touch screen and PLC control system,easy to operate and control.

2)Peristaltic pump filling, accurate metering, no leakage of liquid.

3)No bottle, no filling / no plugging / no capping.

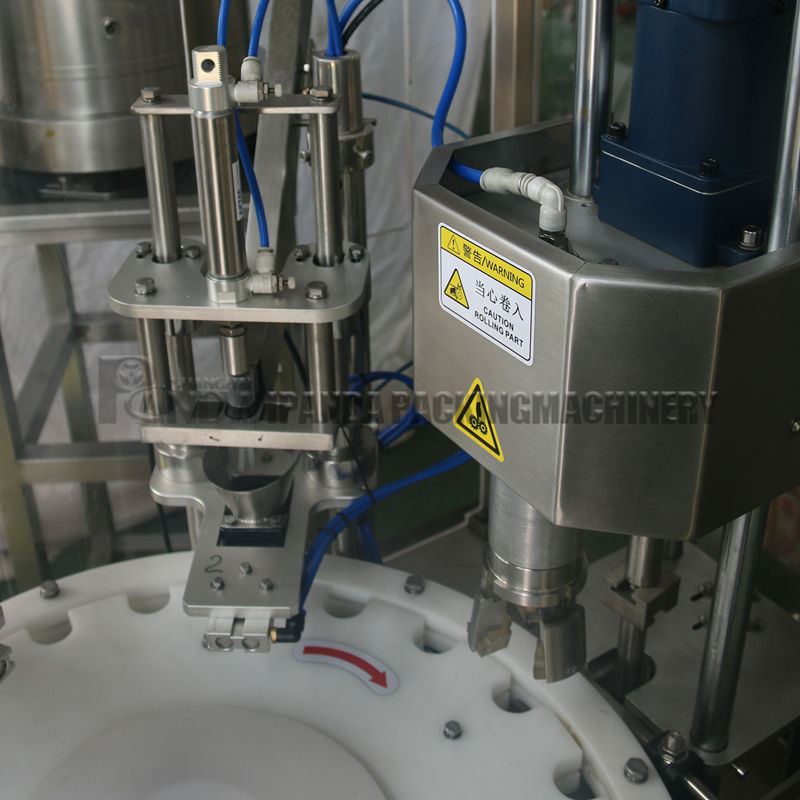

4)Robotic arm capping system, stable and high speed, low failure rate, prevent bottle cap damage.

5)Production speed can be adjusted.

6)Wide range of use, can be used to replace the mold for different bottles filling.

7)The main electrical components of this machine are all used by famous foreign brands.

8)The machine is made of 304 stainless steel material, easy to clean, and the machine meets the requirements of GMP.

Rotary table, No bottle no filling, No cap auto stop, easy for trouble shooting, No air machine alarm, Multiple parameters setting for different caps.

Filling system: lt can achieve automatic stopping when bottles are full, and automatic starting when bottles are lacked on the belt conveyor.

Filling head: Our filling head have 2 jackets You can see the filling split connect with 2 pipes.The outside jacket connect with vacuum suction air pipe.The inner jacket connect with filling perfume material pipe.

Capping station

Capping head all will customize according to customer different cap.

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs

1.Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

FAQ:

Q:How can I get a Manufacturer automatic filling machine from you?

Just send us inquiry through this web page is ok. I will reply your any question within in 3 hours.

Q:Can your company able to offer 1 years gurantee?

Yes it's no problem for our company. During the warranty, if you need any spare parts, we will delivery it to you in DHL for free.

Q:Do you offer a free set of replacement parts for parts that commonly wear out quickly?

All spare parts are always avaliable for delivery. Above 90% spare parts are made by ourselves. Because we have our own processing center, so we can supply at anytime.

Q:What is the whole production line?Can i connect labeling machine,bottle feeder with filling machine in whole line?

I do not know how many meters of conveyors are involved so can not determine the over-all size of the line with all of its components.

We can help you match pipe and pump to transfer material form raw material tank to filling directly., so it can be totally auatomaticlly.We will design and make a layout plan according to customer's factory floor plan.