Manufacturer of Automatic Induction Sealer - Automatic High Speed Vial Liquid Production Line – Ipanda

Manufacturer of Automatic Induction Sealer - Automatic High Speed Vial Liquid Production Line – Ipanda Detail:

Product Display

Overview

Vial Liquid Filling and Stoppering Machine is suitable for the liquid filling and rubber stoppering of glass vials. Machine complete in pleasing matt finished stainless steel construction. The basic unit consists of turntable/unscrambler, SS Stat conveyor belt, Highly efficient and precision built S.S. 316 Syringes, non- toxic synthetic rubber tubing and easy reach compact panel.

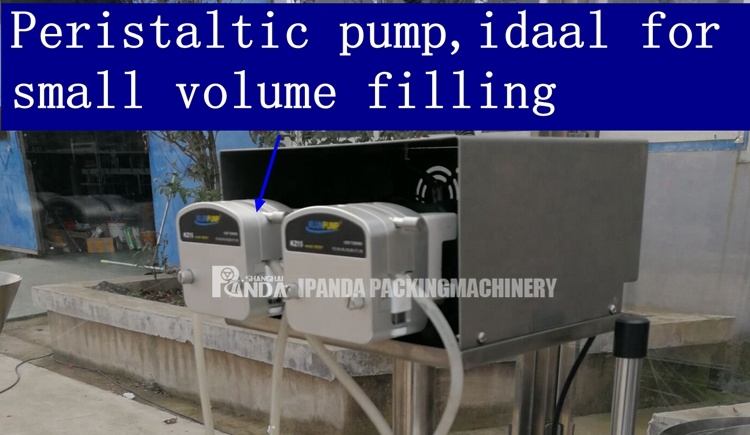

This machine is vial bottles, glass bottles liquid filling and Plugging and capping monoblock Machine, will automatically bottles feeding into machine, then filling and plugging and bottles outlet .Adopt or peristaltic pump or cerimical pump filling, pneumatic roof, electromagnetic vibrator to send, send cap, three knife centrifugal mill cover.Has characteristics of compact structure, precise measurement, reliable operation, it is an ideal equipment of schering bottles potting.

Parameter

| Filling nozzle | 2 nozzles ( according to different speed can customize) |

| Capping head | 1 head ( according to different speed can customize) |

| Filling method | Peristaltic /piston pump (according to different material and filling volue can customize) |

| Capacity | 30 bottles/min ( 2 filling nozzles ,1 capping head) |

| Suitable bottle | Dropper bottle , plug bottle , rubber plug bottle , chubby gorilla bottle, vial. penicillin bottle,spray bottle (can customize to suitable to different type bottle and caps) |

| Filling material | E-liquid,vial,essential oil , spray liquid , oral liquid and so on (can customize) |

Features

- Peristaltic pump or high precision peristaltic pump filling, filling speed is high and filling error is small.

2. Groove cam device positions bottles precisely. Running is stable, change part is east to change.

3. Button control panel is easy to operate and it has high automation degree.

4. Falling bottle auto rejected in the turntable, no bottle, no filling; machine auto stops when no stopper; auto alarms when

insufficient stopper.

5. Equip with auto counting function.

6. Certified, standard electric installation, safety guarantee on operation.

7. Optional acrylic glass protection hood and 100-class laminar flow.

8. Optional pre-filling and after-filling nitrogen filling.

9. The whole machine is designed according to GMP requirements.

Working Process

The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided.

The Machine Details

1)This is filling pipes, it is high quality imported pipes.There are the valves on the pipe, it will suck liquid back after once filling. So filling nozzles will not leakage.

2) The multi roller structure of our peristaltic pump further improves the stability and non impact of filling and makes the liquid filling stable and not easy to blister. It is especially suitable for filling the liquid with high requirement.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

1.We can supply OEC/ODM design.

2.We offer 1 year warranty and free spare parts supply(not man-made broken),we will also prepare enough spare parts delivered

together with the machines.

3.Our machine is designed in simple structure,so that easy for operation and debugging.

4.Engineers available to service machinery

overseas

Pre-sale service

Provide detailed information for customers to understand the equipment’s performance and scope of application. The equipment plan proposed by the customer can also be customized according to the actual requirements of the customer

Installation

After the equipment is shipped to the production site, we will provide tutorials or remote guidance for installation and commissioning; we can send engineers to the site to provide services according to the contract.

One year warranty

After the equipment is shipped to the production site, we will provide tutorials or remote guidance for installation and commissioning: we can send engineers to the site to provide services according to the current situation.

Lifetime warranty

Lifelong tracking service, providing the latest technical support in real time.Machine parts and components are available all vear round to meet customer needs and reduce customel waiting time;for equipment that exceeds a one-vear warranty. only the cost of the parts will be charged for the replacement of damaged parts:a diversified online after-sales service platform is provided, Customers car communicate with us via email, phonewhatsapp, WeChat, QQ, etc.

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5.What should I do if we are not able to operate the machine when we receive it?

Operation manual and video demonstration sent along with the machine to give instructions. Besides, we provide professional after-sale service to solve any problems.

Q6.How could I get the spares on machines?

We will send extra sets of spares and accessories (such as sensors, heating bars, gaskets, O rings, coding letters).Non-artificial damaged spares will be sent freely and shipping free during 1 year’s warranty.

Q7.How can I ensure that I get high-quality machine?

As a manufacturer, we have a strict supervision and control of every manufacturing step from raw materials purchasing, brandschoosing to parts processing, assembling and testing.

Product detail pictures:

Related Product Guide:

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Manufacturer of Automatic Induction Sealer - Automatic High Speed Vial Liquid Production Line – Ipanda , The product will supply to all over the world, such as: Cannes, Detroit, Swedish, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.