Manufactur standard Small Scale Bottle Filling Machine - Automatic Essential Oil Filling And Capping Machine – Ipanda

Manufactur standard Small Scale Bottle Filling Machine - Automatic Essential Oil Filling And Capping Machine – Ipanda Detail:

Product Display

Overview

Filling part of the machine can be used 316L stainless steel injection pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. It is suitable for products of liquid such as essential oil, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent etc.The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

Parameter

| Applied Bottle | 5-200 ml (can be customized ) |

| Productive Capacity | 20-40pcs/min 2 filling nozzles |

| 50-80pcs/min 4 filling nozzles | |

| Filling Tolerance | 0-2% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ,customize |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

Touch screen can be showed in English,Spanish,Rassina,Italian and others language,can be customized according to your requirement.

Features

1. The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2. Including feeder turntable,effective cost/space saving

3. It has intuitive and convenient operation, measuring accurate, positioning precision

4. Fully in accordance with the GMP standard production and passed CE certification

5. No bottle no filling/plugging/capping

The Machine Details

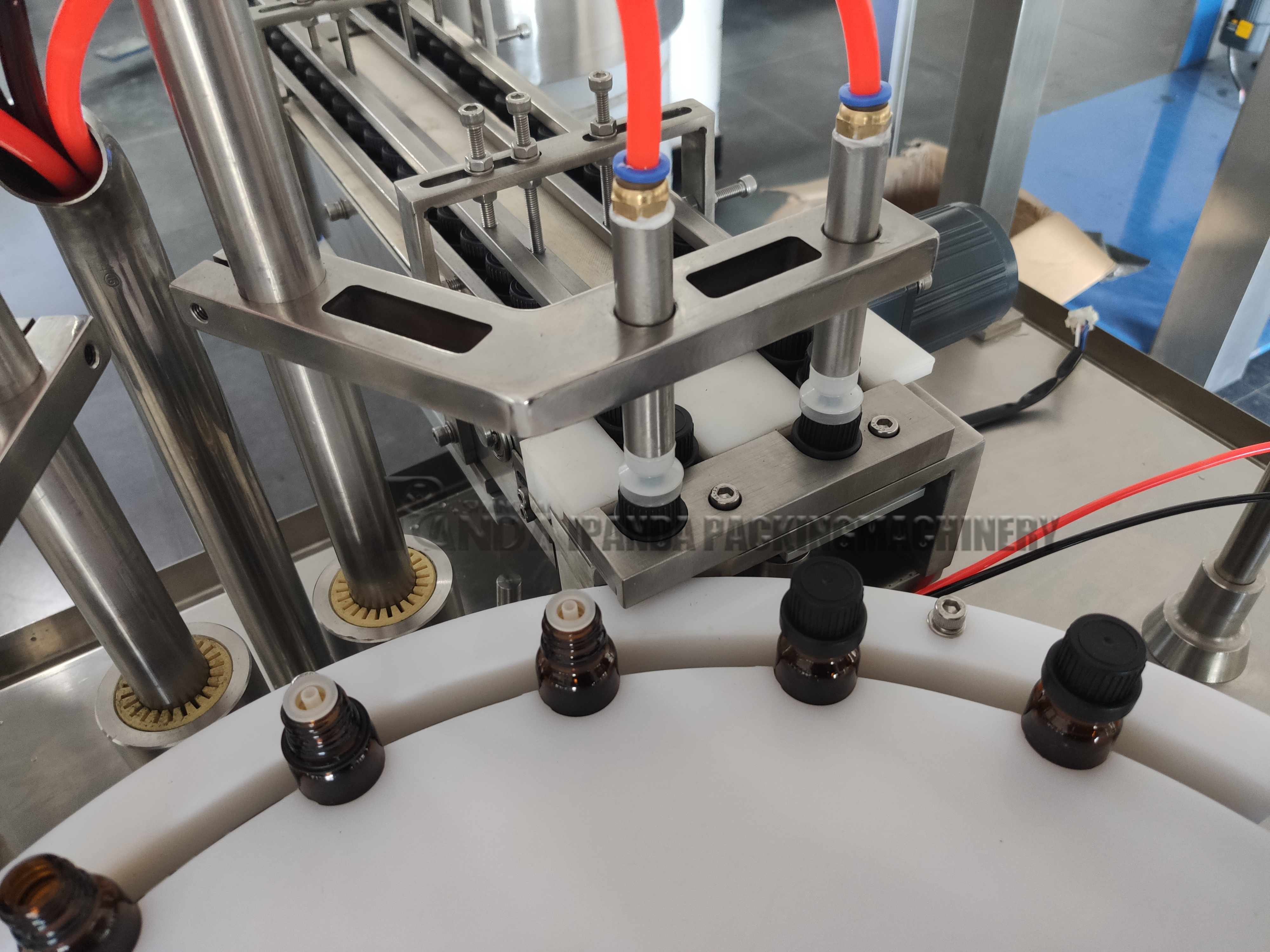

Filling part

Adopt SUS316L Filling nozzles and food grade silicon pipe

high precision. Filling zone protected by interlock guards for safety registration. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

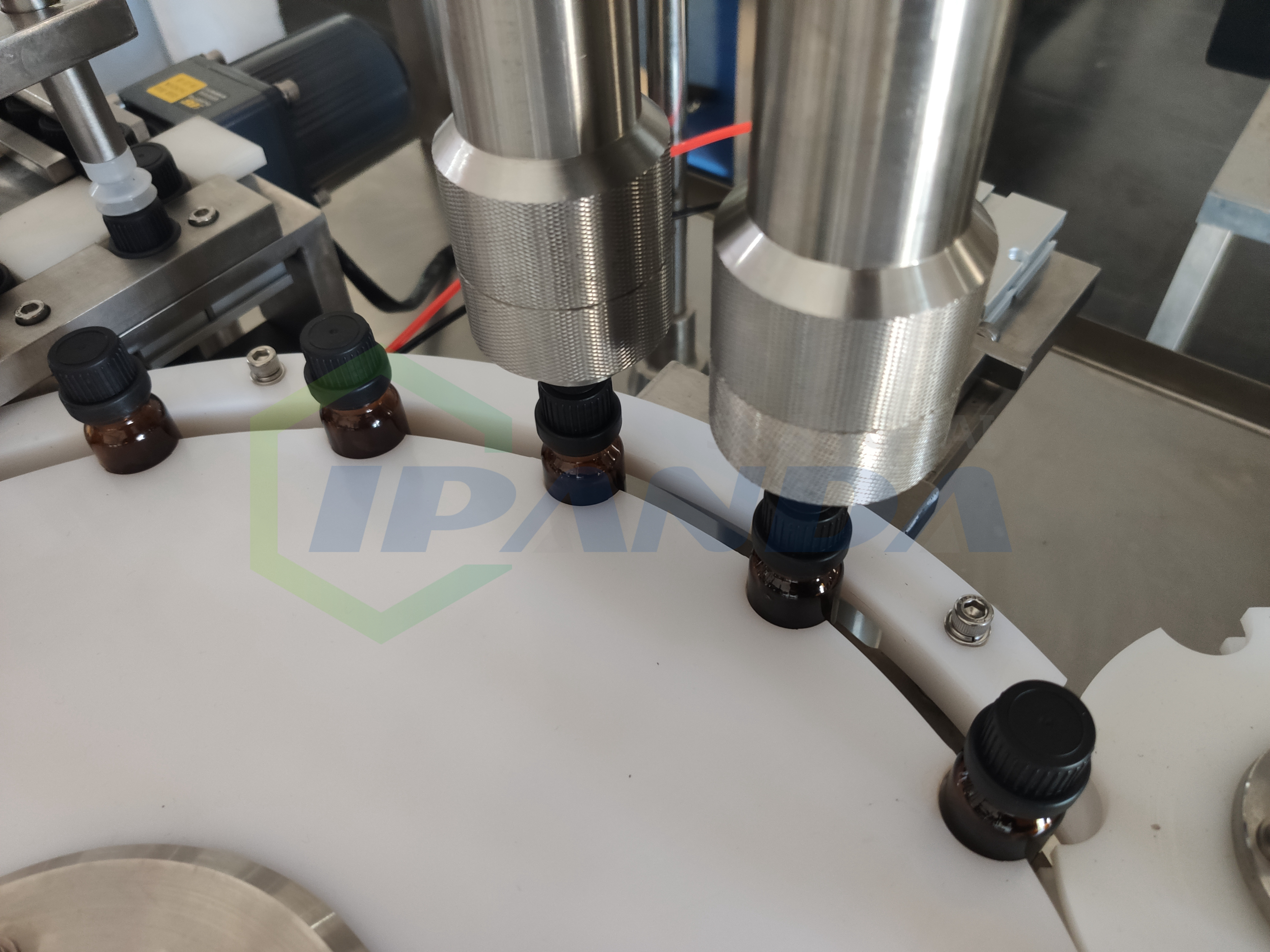

Capping Part: Inserting inner cap-putting cap-screw the cap

Product detail pictures:

Related Product Guide:

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We're ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for Manufactur standard Small Scale Bottle Filling Machine - Automatic Essential Oil Filling And Capping Machine – Ipanda , The product will supply to all over the world, such as: Slovenia, Mombasa, Sao Paulo, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.