Lotion filling machine cream filling capping machine for jar bottle AUTOMATIC

Automatic shampoo filling machine

The machine design and reasonable, with beautiful and nice out look.

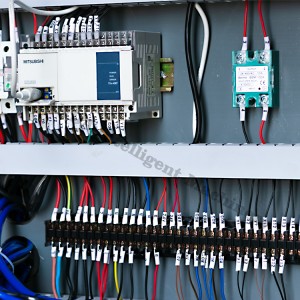

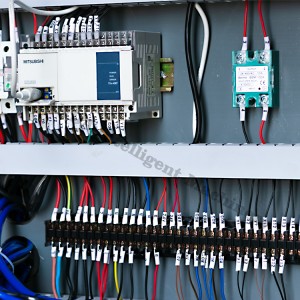

- Adopts famous international electric components.Main power cylinder adopts Germany double function cylinder and electromagnetic switch. Japan MITUBISHI PLC microcomputer,OMRON photoelectric switch, Taiwan touch screen,ensure the outstanding quality and concestent stable function.

- The machine is facilitate to maintain.not need any tool. It's very easy to disassemble and install,cleaning.Adjustment volume could be large range to little range and then to fine adjustment.Could achieve no bottle or lack bottle not filling.High filling volume precision.

- Automatic Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

|

Material |

SUS304 and SUS316L |

||||

|

Filling range |

10-100ml/ 30-300ml/ 50-500ml/ 100-1000ml/ 250-2500mml/ 300-3000ml/ 500-5000ml (can be customized) |

||||

|

Fillling heads |

4 |

6 |

8 |

10 |

12 |

|

Filling speed |

About 2000-2500 |

About 2500-3000 |

About 3000-3500 |

About 3500-4000 |

About 4000-4500 |

|

Filling precision |

±0.5-1% |

||||

|

Power |

220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries) |

||||

|

Air pressure |

0.4-0.6Mpa |

||||

| Machine Size

(L*W*Hmm) |

2000*900*2200 | 2400*900*2200 | 2800*900*2200 | 3200*900*2200 | 3500*900*2200 |

|

Weight |

450Kg |

500Kg |

550Kg |

600Kg |

650Kg |

1. Adopts positive displacement plunger pump for filling, high precision, large range of adjusting dosage, can regulate filling amount of all the pump body as a whole, also can adjust a single pump slightly, quick and convenient.

2. Plunger pump filling system has features of no adsorbing drugs, good chemical stability, high temperature resistance, corrosion resistance, abrasion resistance, long service life, has unique advantages when fill some corrosive liquid.

3.Machine can be customized with 4/6/8/12/14/etc filling heads according to customer's production capacity.

4. Used for various viscosity liquid filling, frequency control,

5. Machine body is made of 304 stainless steel, full compliance with GMP standard.

50ML-5L plastic bottles, glass bottles, round bottles, square bottles, hammer bottles are applicable

Hand sanitizer, shower gel, shampoo, disinfectant and other liquids, with corrosive liquids, paste are applicable.

Anti drop filling nozzles, save product and keeps the machine clean.made of SS304/316.we customize 4/6/8 filling nozzles, for different requested filling speed.

Adopt piston pump

It's suitable for sticky liquid, the adjustment of piston in dosage is convenience and quick, the volume only need to be set on the touch screen directly.

PLC control :This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement.