Liquid Filling Machine

This is our newly developed filling machine. This is our newly developed filling machine. It adopts PLC and touch screen control panel for control material. It is characterized by accurate measuring, advanced structure, stable operating, low noise, large adjusting range, fast filling speed. It is also suitable for the filling of easy volatilization, easy bubbly liquid strong corrosive liquid for rubber, plastic,and high viscosity, liquid, semi-liquid. Operators adjust and meter figure in the touch screen control panel, also can adjust metering of each filling head. The external surface of this machine is made of excellent stainless steel. Good appearance, applied to GMP standard. It adopts PLC and touch screen control panel for control material. It is characterized by accurate measuring, advanced structure, stable operating, low noise, large adjusting range, fast filling speed. Operators adjust and meter figure in the touch screen control panel, also can adjust metering of each filling head. The external surface of this machine is made of excellent stainless steel. Good appearance, applied to GMP standard .

|

Model |

Automatic liquid filling machine |

|

Filling nozzle number |

2/4/6/8/12 customize |

|

filling volume |

100-1000ml(can be customized) |

|

filling speed |

15-100bottles/min |

|

filling accuracy |

≤±1% |

|

total power |

3.2kw |

|

power supply |

1ph .220v 50/60HZ |

|

machine size |

L2500*W1500*H1800mm (customized) |

|

Net weight |

600kg(customized) |

1. 304 Stainless steel construction and the material contact parts.

2. Controlled by panasonic servo motor or cylinder.

3. The filling blocked nozzles are anti drops, silk, and auto cut viscous liquid.

4. Easy to maintain, no special tools are required.

5. Diving nozzles for bottom up filling of foaming products if need.

Filling Nozzles

Piston-type filling machine, self-priming filling, single cylinder drives a single piston to extract the material into themetering cylinder, and then pneumatically push the piston into the container through the material tube, the filling volume is determined by adjusting the cylinder stroke, filling accuracy High, easy to use and flexible.

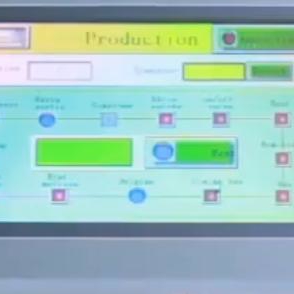

PLC+ touch screen

The overall program control adopts PLC+ touch screen, and the filling volume and filling speed can be adjusted conveniently and quickly.

Pneumatic Filling

The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specifications without replacing parts.With anti-dripping function,can control each nozzle separately.

Adopt piston pump