Large Capacity Pharmaceutical Vial Oral Liquid Filling Production Line

Vial Liquid Filling and Stoppering Machine is suitable for the liquid filling and rubber stoppering of glass vials. Machine complete in pleasing matt finished stainless steel construction. The basic unit consists of turntable/unscrambler, SS Stat conveyor belt, Highly efficient and precision built S.S. 316 Syringes, non- toxic synthetic rubber tubing and easy reach compact panel.

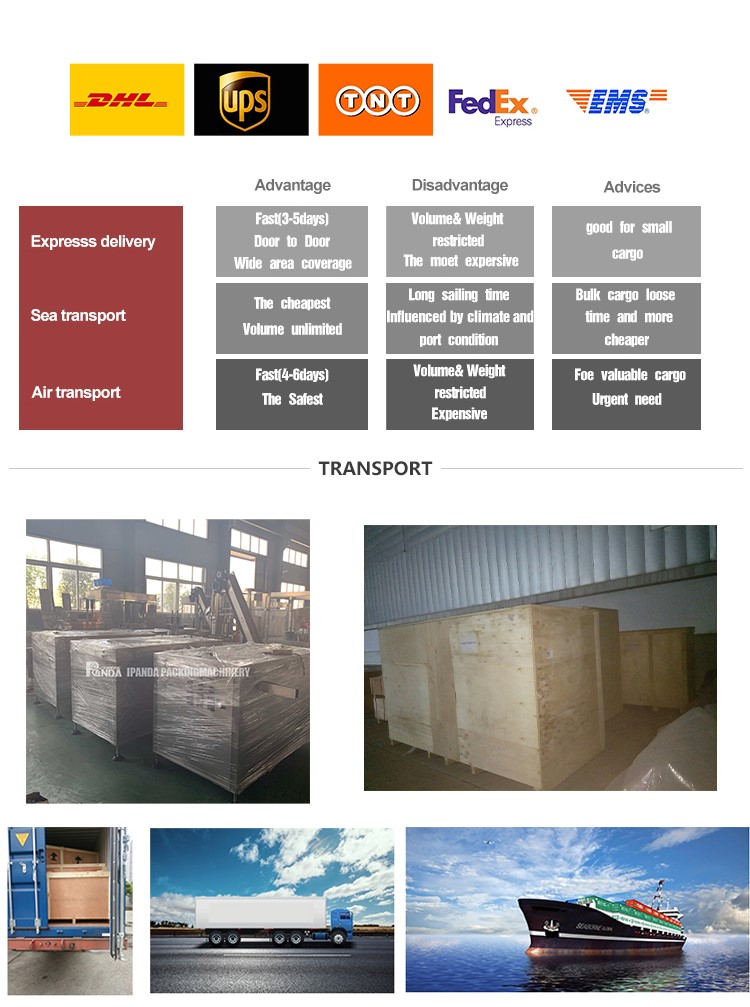

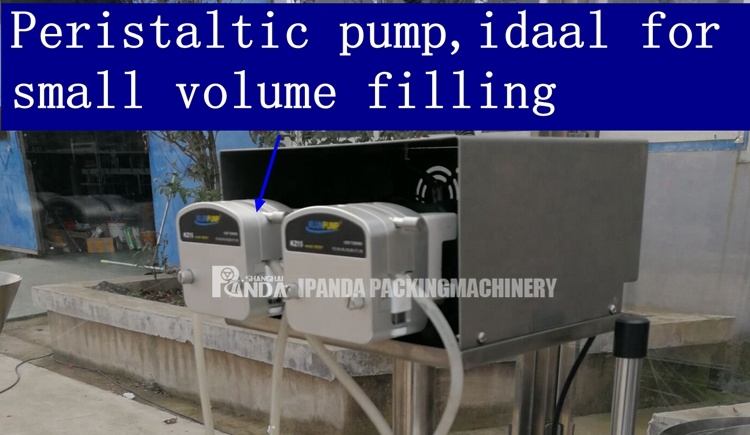

This machine is vial bottles, glass bottles liquid filling and Plugging and capping monoblock Machine, will automatically bottles feeding into machine, then filling and plugging and bottles outlet .Adopt or peristaltic pump or cerimical pump filling, pneumatic roof, electromagnetic vibrator to send, send cap, three knife centrifugal mill cover.Has characteristics of compact structure, precise measurement, reliable operation, it is an ideal equipment of schering bottles potting.

| Filling nozzle | 2 nozzles ( according to different speed can customize) |

| Capping head | 1 head ( according to different speed can customize) |

| Filling method | Peristaltic /piston pump (according to different material and filling volue can customize) |

| Capacity | 30 bottles/min ( 2 filling nozzles ,1 capping head) |

| Suitable bottle | Dropper bottle , plug bottle , rubber plug bottle , chubby gorilla bottle, vial. penicillin bottle,spray bottle (can customize to suitable to different type bottle and caps) |

| Filling material | E-liquid,vial,essential oil , spray liquid , oral liquid and so on (can customize) |

- Peristaltic pump or high precision peristaltic pump filling, filling speed is high and filling error is small.

2. Groove cam device positions bottles precisely. Running is stable, change part is east to change.

3. Button control panel is easy to operate and it has high automation degree.

4. Falling bottle auto rejected in the turntable, no bottle, no filling; machine auto stops when no stopper; auto alarms when

insufficient stopper.

5. Equip with auto counting function.

6. Certified, standard electric installation, safety guarantee on operation.

7. Optional acrylic glass protection hood and 100-class laminar flow.

8. Optional pre-filling and after-filling nitrogen filling.

9. The whole machine is designed according to GMP requirements.

The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided.

1)This is filling pipes, it is high quality imported pipes.There are the valves on the pipe, it will suck liquid back after once filling. So filling nozzles will not leakage.

2) The multi roller structure of our peristaltic pump further improves the stability and non impact of filling and makes the liquid filling stable and not easy to blister. It is especially suitable for filling the liquid with high requirement.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

1.We can supply OEC/ODM design.

2.We offer 1 year warranty and free spare parts supply(not man-made broken),we will also prepare enough spare parts delivered

together with the machines.

3.Our machine is designed in simple structure,so that easy for operation and debugging.

4.Engineers available to service machinery overseas