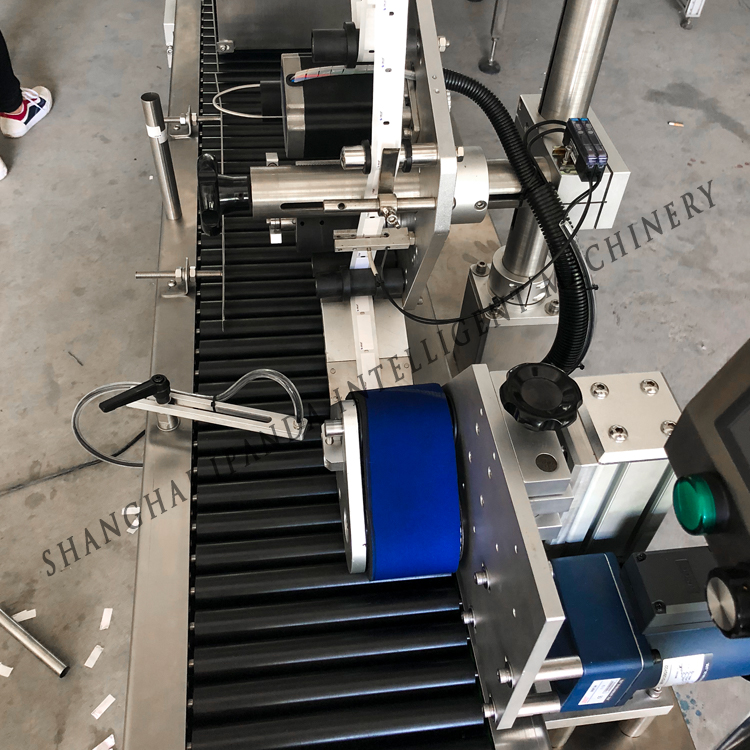

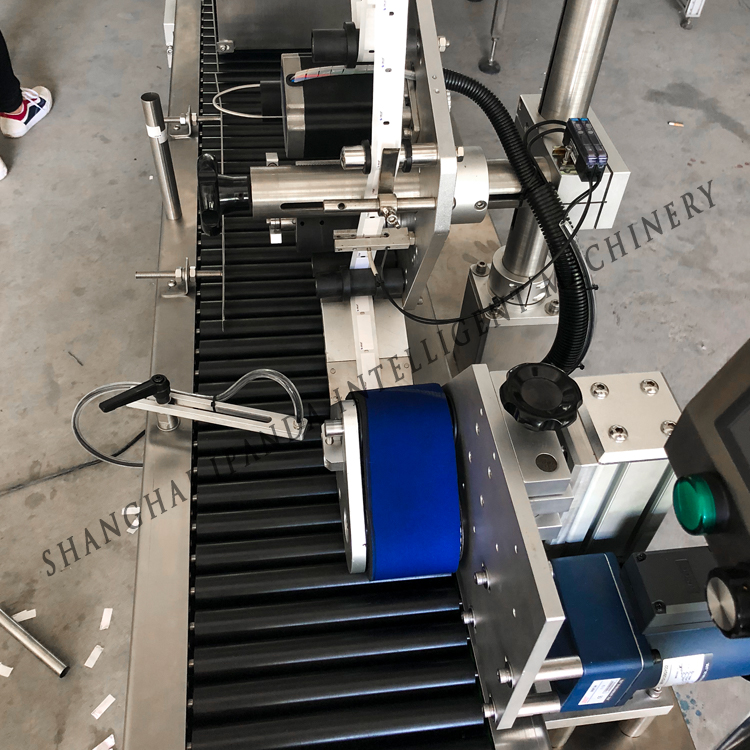

Automatic reagent horizontal test tube labeling machines

Suitable for circumferential or semi-circular labeling of cylindrical objects with small diameters that are not easy to stand.Horizontal transfer and horizontal labeling are used to increase stability and labeling efficiency is very high. Widely used in cosmetics, food, medicine, chemicals, stationery, electronics, hardware, toys, plastics and other industries. Such as:lipstick,oral liquid bottle, small medicine bottle, ampoule, syringe bottle, test tube, battery, blood, pen, etc.

| Yield capacity(bottle/min) | 40-60bottles/min |

| Standard label speed(m/min) | ≤50 |

| Suitable product | Round small tubes, pens, or other rollers |

| Label accuracy | ±0.5 to 1mm error |

| Applicable label specification | Glassine paper, transparent or opaque |

| Dimension(mm) | 2000(L) × 850(W) × 1280(H) (mm) |

| Label roll(inside)(mm) | 76mm |

| Label roll(outside)(mm) | £300mm |

| Weight(kg) | 200kg |

| Power(w) | 2KW |

| Voltage | 220V/380V ,50/60HZ,single/three phase |

| Relative temperature | 0 ~ 50 ºC |

1. Adopt mature PLC control system technology, make the whole machine stable and high-speed

2. Adopt touch screen control system,make opreation simple, practical and efficient

3. Advanced pneumatic code system technology, make the printed letter clear, fast and stable

4. Wide application, adapted to various sizes of round bottles

5. Roll extrusion bottle, so the labels attached more solid

6. Production line is for optional,also turntable is optional for collecting,sorting and packaging

The labeling position of height can be adjusted.

The machine has many functions such as guiding,separating,labeling,attaching,counting.

Adopting new vertical hopper automatic splitting structure applying flexible bottle dividing technology and flexible coating conveying technology, effectively eliminating the bottleneck caused by the error of the bottle itself and improving stability;