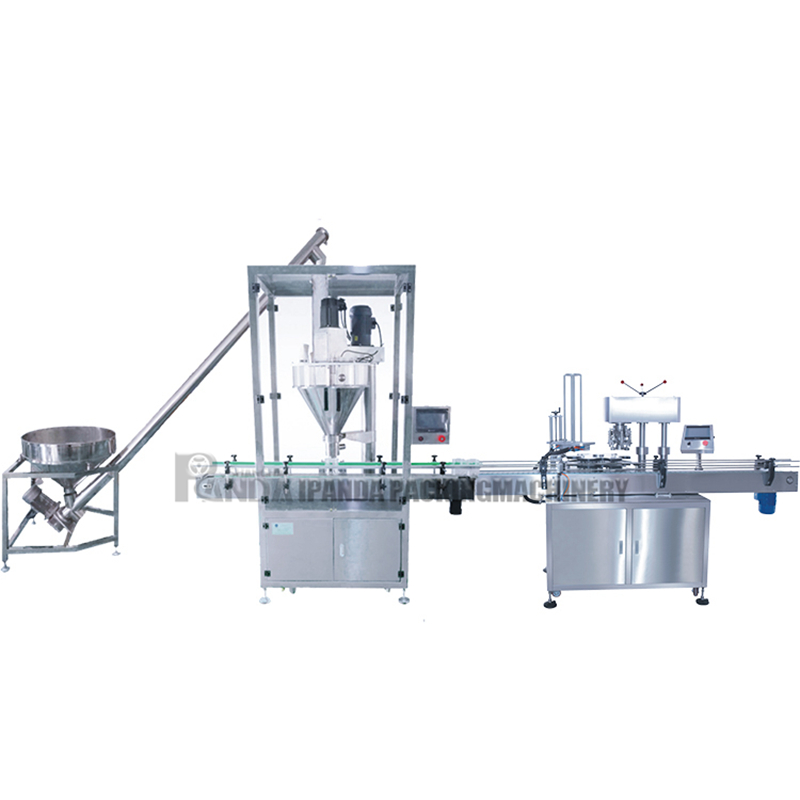

High capacity automatic powder filling capping and labeling machine

The equipment is my company in accordance with the latest GMP standard design and development of a new canned machine, the machine application of the latest technology, design more reasonable, more concise, more solid. Automatic completion into the tank, measurement, filling, waste and other work, for packaging powder granular materials, such as milk powder, monosodium glutamate, solid drinks, grape, rice and so on.

This machine is used in dry powder, coffee powder, powder granular additives, sugar, monosodium glutamate, solid powder medicine, dyes, spices, medicine, chemical industry, food and other fields

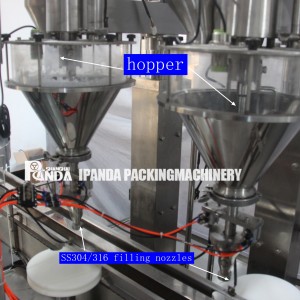

| Filling nozzle | 1/2/4 nozzles(customized) |

| Metering Mode | Auger rotation filling |

| Packaging weight | 10g-1500g |

| Power Supply | 220V/380 50/60Hz |

| Packaging Speed | 10-60 bottles/min |

| Accuracy | 10-100gr≤±1%/100-1000g≤±0.8% |

| Machine weight | 700kg |

| Power | 1.5kw |

| Single machine noise | ≤50db |

| Machine dimension | 1600*850*2000mm |

1, PLC control system, man-machine interface, work at a glance, all parameters can be added to the program module, after use.

2, the use of tank or bottle-like container packaging, automatic configuration into the bottle into the tank system, can be achieved without bottles, bottles do not pack.

3, the weight of ultra-poor alarm, fault alarm tips and waste discharge function, do not miss each bottle of substandard products to ensure that products pass rate.

4, the whole structure, reasonable layout, replacement of packaging varieties, clean up and for the convenience.

5, the use of specific gravity feedback tracking and high-speed reaction clutch brake to promote the spiral, greatly improving the packaging accuracy.

6, mechanical stability and durability, less maintenance costs.

Adopt PLC control

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction.

The size of bottles and cans can be adjusted in height, with large adjustment range, convenient and fast operation.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

The machine has a vibrating mechanism device, which can avoid the material with poor fluidity remaining in the hopper during filling, which will affect the filling accuracy.

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company's equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of "Good quality , Good service, Good prestige". We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

FAQ

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke, how to solve the problem?

A7: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q8: Do you have manual or operation video for us to know more about the machine?

A8: Yes, we will send you the manual and operation video after you ask for us.