Good quality Wine Bottle Labeler - Rotary Positioning OPP BOPP Rollfed Hot Glue Label Labeling Packing Packaging Machine – Ipanda

Good quality Wine Bottle Labeler - Rotary Positioning OPP BOPP Rollfed Hot Glue Label Labeling Packing Packaging Machine – Ipanda Detail:

Product Display

Overview

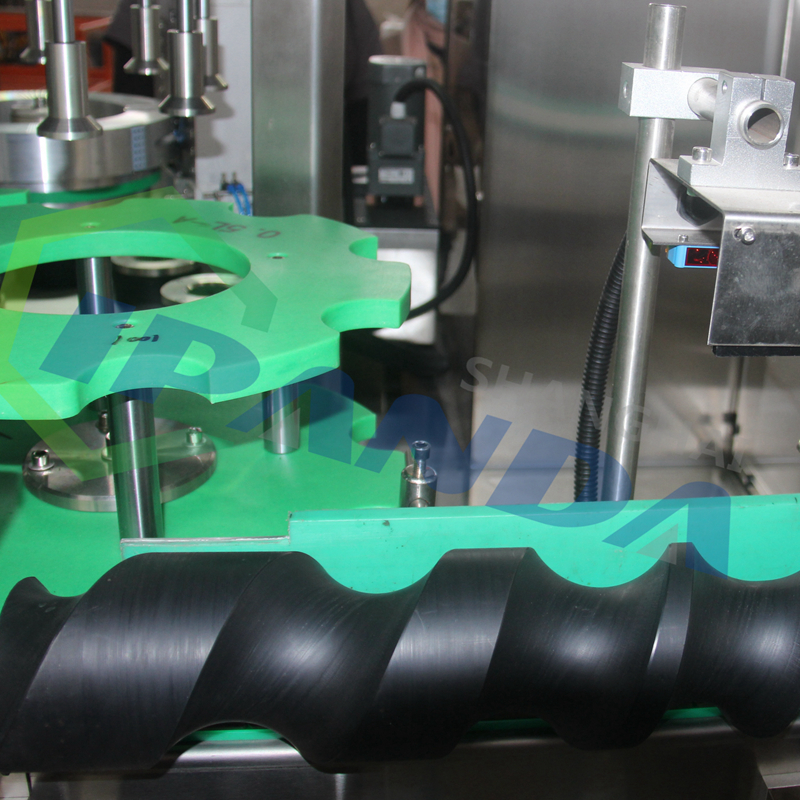

The containers are picked up by the in feed star wheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells.

The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point.

Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. The label with the glue strip on its leading edge is transferred to the container. This glue strip ensures an exact label positioning and a positive bond. As the container is rotated during label transfer, labels are applied tightly. Gluing of the trailing edge ensures proper bonding.

Main Technical Parameters

| Capacity | 350 bottles/min |

| Label specification | Length:125-325mm,Height:20-150mm |

| Available bottle dimension | Diameter:40-105mm, height=80-350MM |

| Gluing way | Roll painting(about 10mm, both label head and tail) |

| Glue Consumption | l kg/ 100,000 bolttles (label height:50mm) |

| Compressed Air Pressure | MIN5.0bar MAX8.0bar |

| Power | 8KW |

Process: feed bottle → pre-position →label cutting → gluing → labeling→ label by press out → finished

Product Details

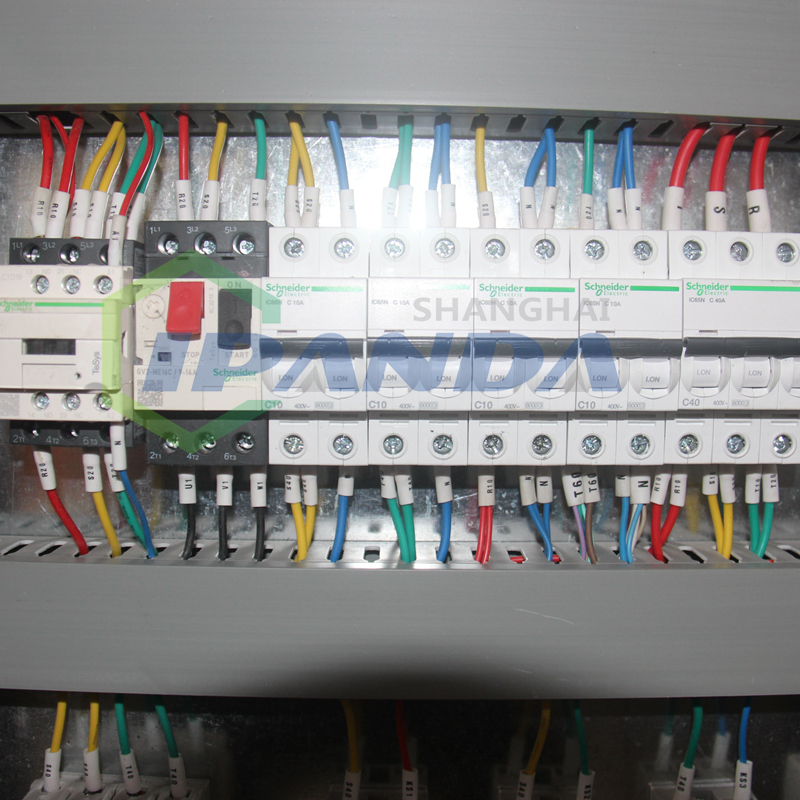

Excellent Components

From in-feed and out-feed starwheel , vacuum drum,gluing system to cutter ,It gets all-around labeling quality control.

High precision, compact structure, good stability,low glue consumption.

Quality Material

Screw, star wheel and stainless steel are made of high-end materials with good thickness and density.

Resist wear and corrosion.Long service life and stable performance.

High Safety

Thermal baffle are fitted top revent burns of glue box.Safety interlock and failure alarm device ensure safe and stable running.

lnching control, adjust and change bottle and label easily.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Products Good quality, Reasonable Value and Efficient Service" for Good quality Wine Bottle Labeler - Rotary Positioning OPP BOPP Rollfed Hot Glue Label Labeling Packing Packaging Machine – Ipanda , The product will supply to all over the world, such as: Lebanon, Munich, Wellington, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.