Fully Automatic Liquid Plastic Bottle Detergent Filling Machine

This automatic cylinder drive piston pump liquid filling machine is a new product of our company based on the advanced technology of other countries. This machine use Servo motor drive stainless rotary pump to fill, and it can use different filling heads to meet customers' production demands, Besides, it can also link to other cap-feeder and capping machines in the production line. It takes up only a little room, economical and practical, widely used for filling liquids in industries like pharmaceuticals, pesticides, chemicals, food, cosmetics, etc. It is in full compliance with the GMP requirements.

| Name | Automatic liquid filling machine |

| Filling dosage | 50-500ml 100-1000ml 500-5000ml |

| Hopper Volume | 120L |

| Fill Capacity | 1000-5000B/H(at the base of 500ml) |

| Accuracy | <± 1.0%(on the base of 1000ml) |

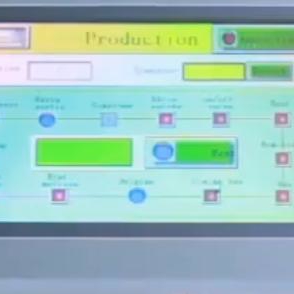

| Control system | PLC & Touch screen |

| Power supply | 220V 50Hz 1phase/380V 50HZ 3phase 0.2KW |

| Air consumption | 0.3-0 .7 Mpa |

| G.W. | 450KG |

| Power | 0.5KW |

| Dimension | customized |

1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize.

2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry.

3. PLC control system, frequency conversion adjusting speed, high degree automation.

4. No bottle, no filling, auto count the quantity. And have the anti-drop device.

5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate.

6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble.

7. The whole machine is suitable bottles in different size, easy adjusting, and can be finished in short time.

Filling Nozzles

Piston-type filling machine, self-priming filling, single cylinder drives a single piston to extract the material into themetering cylinder, and then pneumatically push the piston into the container through the material tube, the filling volume is determined by adjusting the cylinder stroke, filling accuracy High, easy to use and flexible.

PLC+ touch screen

The overall program control adopts PLC+ touch screen, and the filling volume and filling speed can be adjusted conveniently and quickly.

Pneumatic Filling

The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specifications without replacing parts.With anti-dripping function,can control each nozzle separately.

Adopt piston pump

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

Company information

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

Why Choose Us

- Dedication to Research & Development

- Experienced Management

- Better understanding of Customer requirement

- One Stop solution provider with Broad Range Offering

- We can supply OEM&ODM design

- Continuous Improvement with Innovation

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide new one or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it at your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer's best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be covered by buyer's side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging.

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.