Full Automatic Bag in Box Liquid Paste Filling Machine

The bag-in-box filling machine adopts the flow meter measurement method, the filling precision is high, and the setting and adjusting the filling amount is very intuitive and convenient; the machine has novel design, reasonable and compact structure, and can automatically complete the capping, quantitative filling, vacuuming, Pressing and other processes.

|

Working principle

|

flow meter to control

|

|||

|

Filling precision

|

±0.5-1%

|

|||

|

Material entrance pressure

|

≤0.3-0.35Mpa

|

|||

|

Filling range

|

1-20L

|

|||

|

Filling speed

|

400-500bags/h(for 1L) 180-200bags/h(for 5L)

|

|||

|

Material entrance pressure

|

≤0.3-0.35Mpa

|

|||

|

Power

|

≤0.38KW

|

|||

|

Air consumption

|

0.2m3/min

|

|||

|

Working pressure

|

0.4-0.6Mpa

|

|||

|

Voltage

|

220/110V 50/60 Hz

|

|||

|

Filling accuracy

|

≤1%

|

|||

|

Package size

|

1050*850*1550mm

|

|||

|

Weight

|

160KG

|

|||

It can be widely used in bag-in-box filling applications for such liquid materials as drinking water, wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.

1.This machine is mainly made of stainless steel, enjoy beautiful appearance. The parts that contact material are made of 304 stainless steel and food grade plastic tube. CIP cleaning is available to meet with sanitation.

2.Full automati finish flling pulling out the cap, vacuum pumping, quantitative flling,pressing the capping at one step.

3.Adopts flow meter for measuring which is with high flling precision, Easy to adjust flling,volumes.

4.This machine is with vacuum function, Enable to vacuum pumping before flling which helps to extend product shelf life. And nitrogen charging system can be customized.

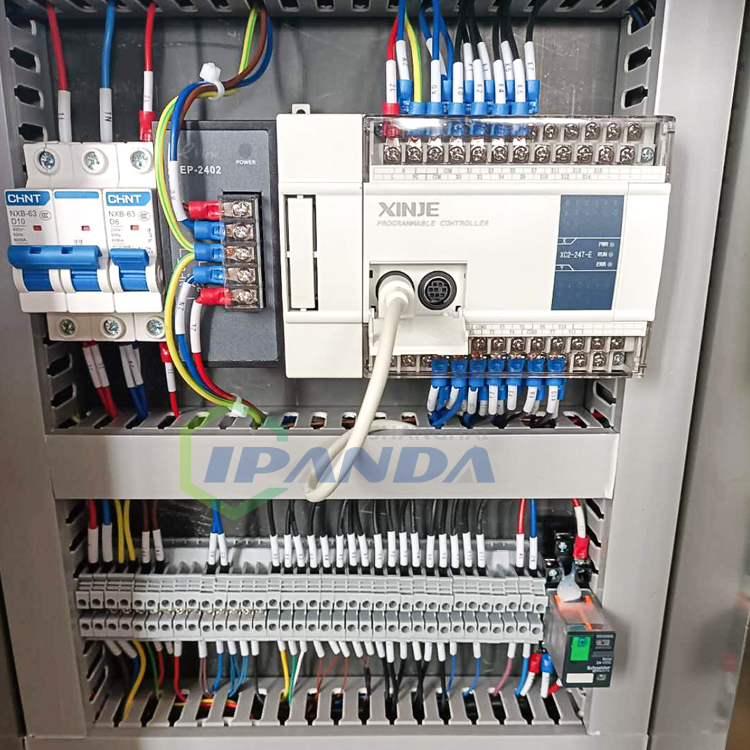

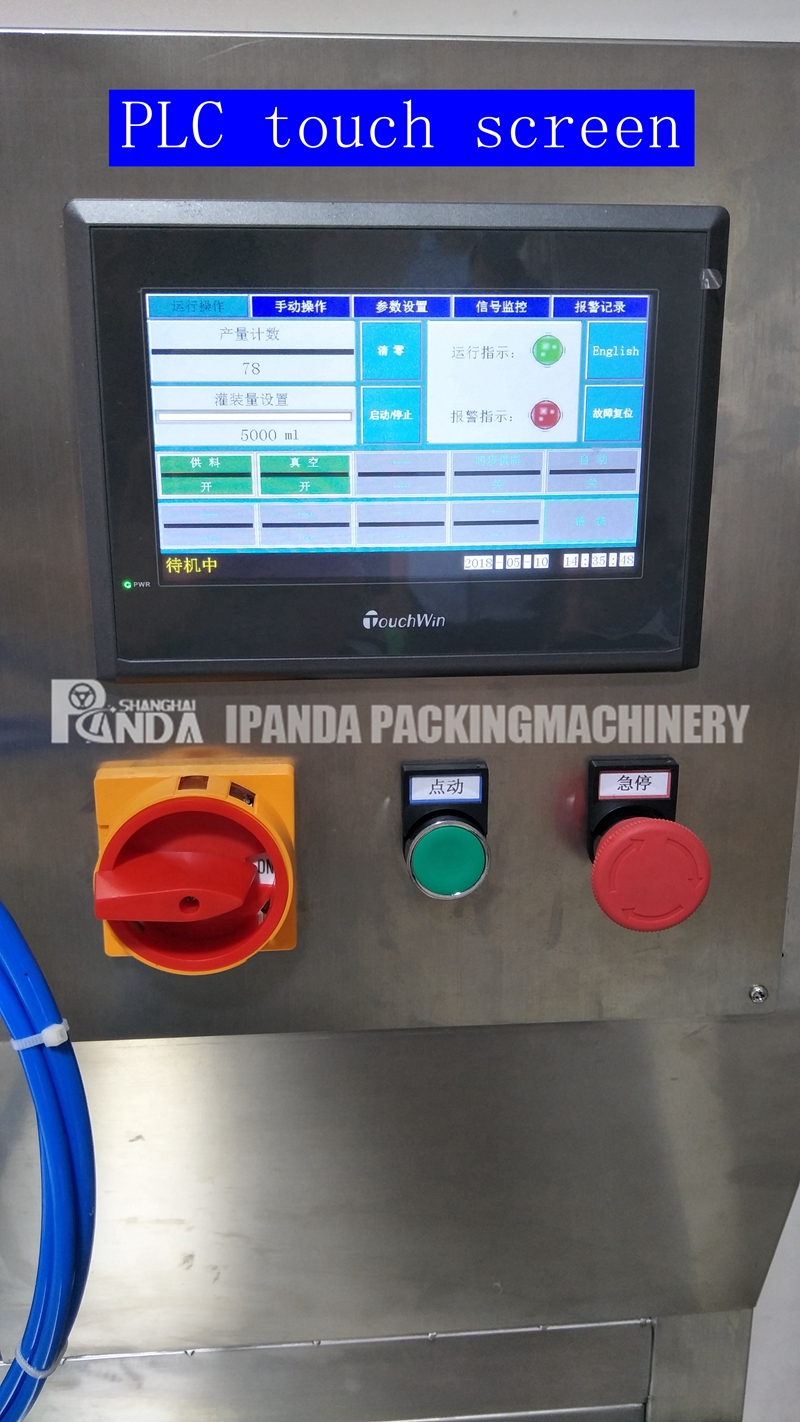

5.lt is controlled by PLC and touch screen with accurate precision, advanced structure and stable performance.

6.A nitrogen system can be added according to the client's requirement.

7.The electric and pneumatic components are products of world-renowned brands with low failure rate, reliable performance and long service life.

Company information

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

The talent team of Ipanda Intelligent Machinery Gathers product experts,sales experts and after-sales service staffs,and upholds the business philosophy of “High performance, Good service,Good prestige”.Our engineers are responsible and professional with more than 15 years experience in the industry.We will according to your product samples and filling material return the real effect of packing Until the machine work well ,we will not ship it to your side.Aimed at offering high level products to our customers, we adopt the SS304 material, reliable components for the products. And all the machines have reached CE standard. Overseas after-sales service is also available, our engineer has gone for many countries for service support. We are always striving to offer high quality machines and service to customers.

Why Choose Us

Dedication to Research & Development

Experienced Management

Better understanding of Customer requirement

One Stop solution provider with Broad Range Offering

We can supply OEM&ODM design

Continuous Improvement with Innovation

FAQ

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke, how to solve the problem?

A7: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q8: Do you have manual or operation video for us to know more about the machine?

A8: Yes, we will send you the manual and operation video after you ask for us.