Factory wholesale Peristaltic Filling Machine - Automatic Paste Liquid Servo Motor Filling Machine – Ipanda

Factory wholesale Peristaltic Filling Machine - Automatic Paste Liquid Servo Motor Filling Machine – Ipanda Detail:

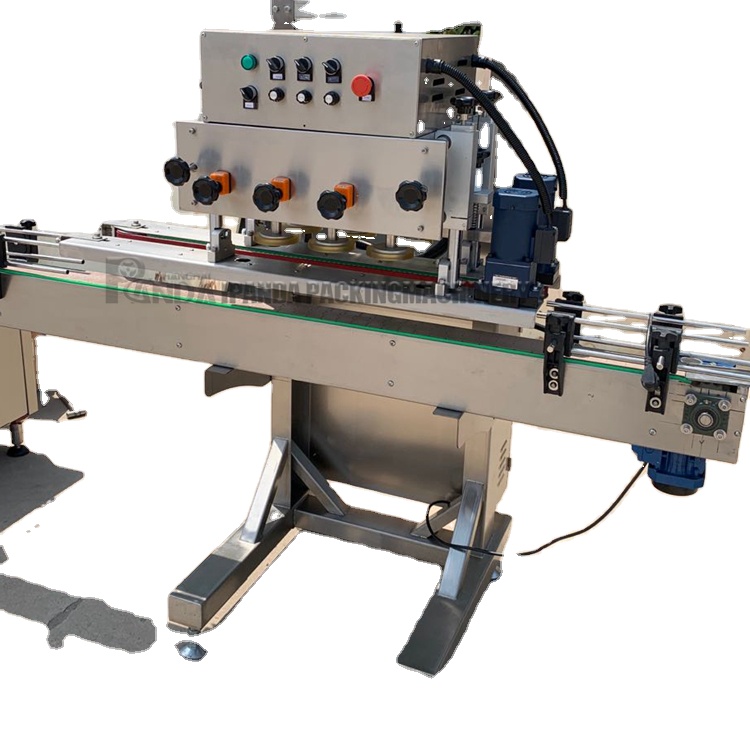

Product Display

Overview

This product is a new type of filling machine meticulously designed by our company. This product is a linear servo paste liquid filling machine, which adopts PLC and touch screen automatic control. It has the advantages of accurate measurement, advanced structure, stable operation, low noise, large adjustment range, and fast filling speed. Moreover, it can be adapted to liquids that are volatile, crystallized and foamable; liquids that are corrosive to rubber and plastics, as well as high-viscosity liquids and semi-fluids. The touch screen can be reached with one touch, and the measurement can be fine-tuned with a single head. The exposed parts of the machine and the contact parts of the liquid material are made of high-quality stainless steel, the surface is polished, and the appearance is beautiful and generous.

Parameter

|

Feeding method |

Automatic feeding |

|

Filling speed |

20-80 bottle/min customize |

|

Filling volume |

50-1000ml customize |

|

Filling way |

Piston type |

|

Control |

PLC control |

|

Filling accuracy |

±1% |

|

Motor type |

Servo motor |

|

Filling nozzles |

Can be customize |

|

Oversize |

3000*1300*2100mm |

Features

1. Servo motor drive mode is adopted, the filling speed is stable, and the air consumption is small. The filling mode of fast first and then slow can be set, which is more intelligent and humane.

2. Using domestic and foreign well-known brands of electrical and pneumatic components, the failure rate is low, the performance is stable, and the service life is long;

3. The adjustment of operating data is simple, high-precision filling, and easy to use;

4. All contact materials are made of stainless steel, which is not easy to be corroded, simple to disassemble, easy to clean, and meets food hygiene standards;

5. It is easy to adjust the filling volume and filling speed, with no bottle and no material to stop filling and automatic feeding. The liquid level automatically controls the feeding, and the appearance is beautiful;

6. The filling nozzle can be changed to submerged filling, which can effectively prevent the filling material from foaming or splashing, and is suitable for filling liquids that are easy to foam;

7. The filling nozzle is equipped with an anti-drip device to ensure that there is no wire drawing or dripping during the filling;

8. No need to replace parts, you can quickly adjust and replace bottles of different shapes and specifications, with strong applicability.

The Machine Details

Filling processing:

Put the bottle on the conveyor-Automatic detection-Automatic positioning of bottle mouth-Automatic quantitative filling-automatic bottle out

Automatic material filling, 200L storage hopper is equipped with a liquid level device, when the material is lower than the liquid level device, it will automatically replenish the material.

Sensor positioning is accurate, automatic shutdown function, no bottle no filling, automatic shutdown function for accumulated bottles, sensitive response and long life

Chain conveyor belt

Stable operation, no pouring, abrasion resistance, sturdiness and durability

Adopt PLC control, Japanese PLC program control, intuitive man-machine interface, convenient operation, PLC control control, loading picture album

Application

Heavy sauces,food oils salsas, salad dressings,cosmetic creams, heavy shampoo gels, and conditioners, paste cleaners and waxes, adhesives, heavy oils and lubricants.

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Factory wholesale Peristaltic Filling Machine - Automatic Paste Liquid Servo Motor Filling Machine – Ipanda , The product will supply to all over the world, such as: Mombasa, Bolivia, South Korea, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.