Factory source Bottle Cover Sealing Machine - Automatic powder bottle filling machine/chemical powder filling line – Ipanda

Factory source Bottle Cover Sealing Machine - Automatic powder bottle filling machine/chemical powder filling line – Ipanda Detail:

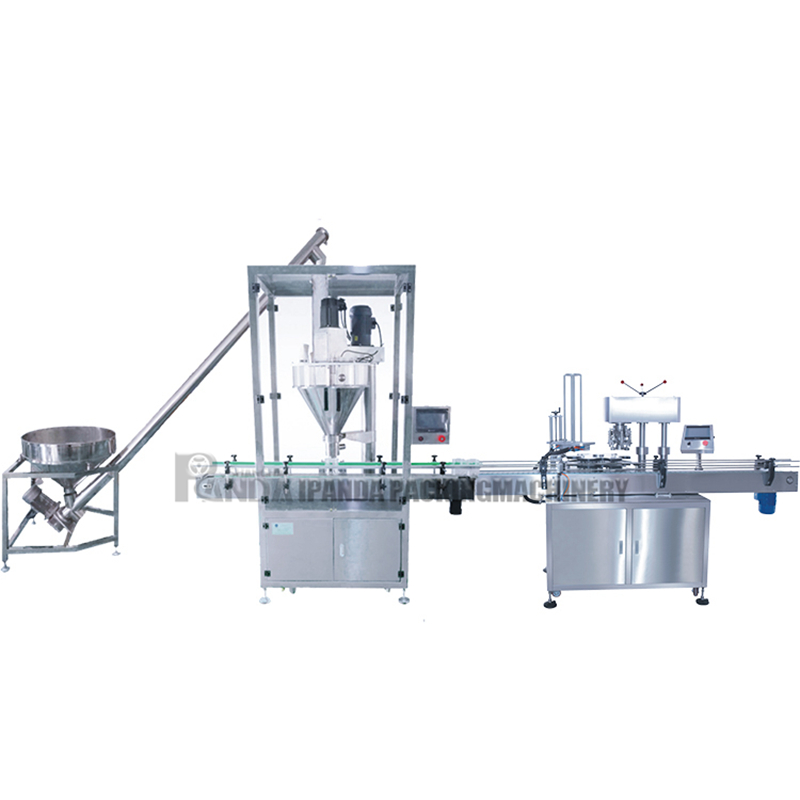

Product Display

Overview

This powder filling machine adopt auger to measure and fill powder and granular,with high filling speed and filling accuracy.It adopts feed screw by touch screen,which is suitable for all kind powder materials,such as:coffee,spice powder,white sugar ect.

Application

This machine is used in dry powder, coffee powder, powder granular additives, sugar, monosodium glutamate, solid powder medicine, dyes, spices, medicine, chemical industry, food and other fields

Parameter

| Filling nozzle | 1/2/4 nozzles(customized) |

| Metering Mode | Auger rotation filling |

| Packaging weight | 10g-1500g |

| Power Supply | 220V/380 50/60Hz |

| Packaging Speed | 10-60 bottles/min |

| Accuracy | 10-100gr≤±1%/100-1000g≤±0.8% |

| Machine weight | 700kg |

| Power | 1.5kw |

| Single machine noise | ≤50db |

| Machine dimension | 1600*850*2000mm |

Features

1. Adopt a stepping motor and electronic weighing technology, the aircraft is slightly lower cost in comparison with the servo motor, and it is economical and practical.

2. Spiral cutting, light-control technology.

3. Specifications: The same machine within the 2-5000g adjustment and replacement of the keyboard under different specifications of material spiral continuously adjustable.

4. Scope: There is a certain fluidity of powder materials, containers (bags, cans)unlimited.

5. Materials due to changes in weight and material level of error correction can be automatically tracked.

6. Photoelectric switch control, only manual bagging, bag clean, easy to seal.

7. Screw feeder can be equipped with automatic feeding control.

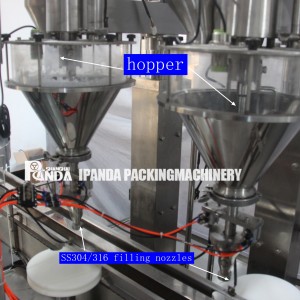

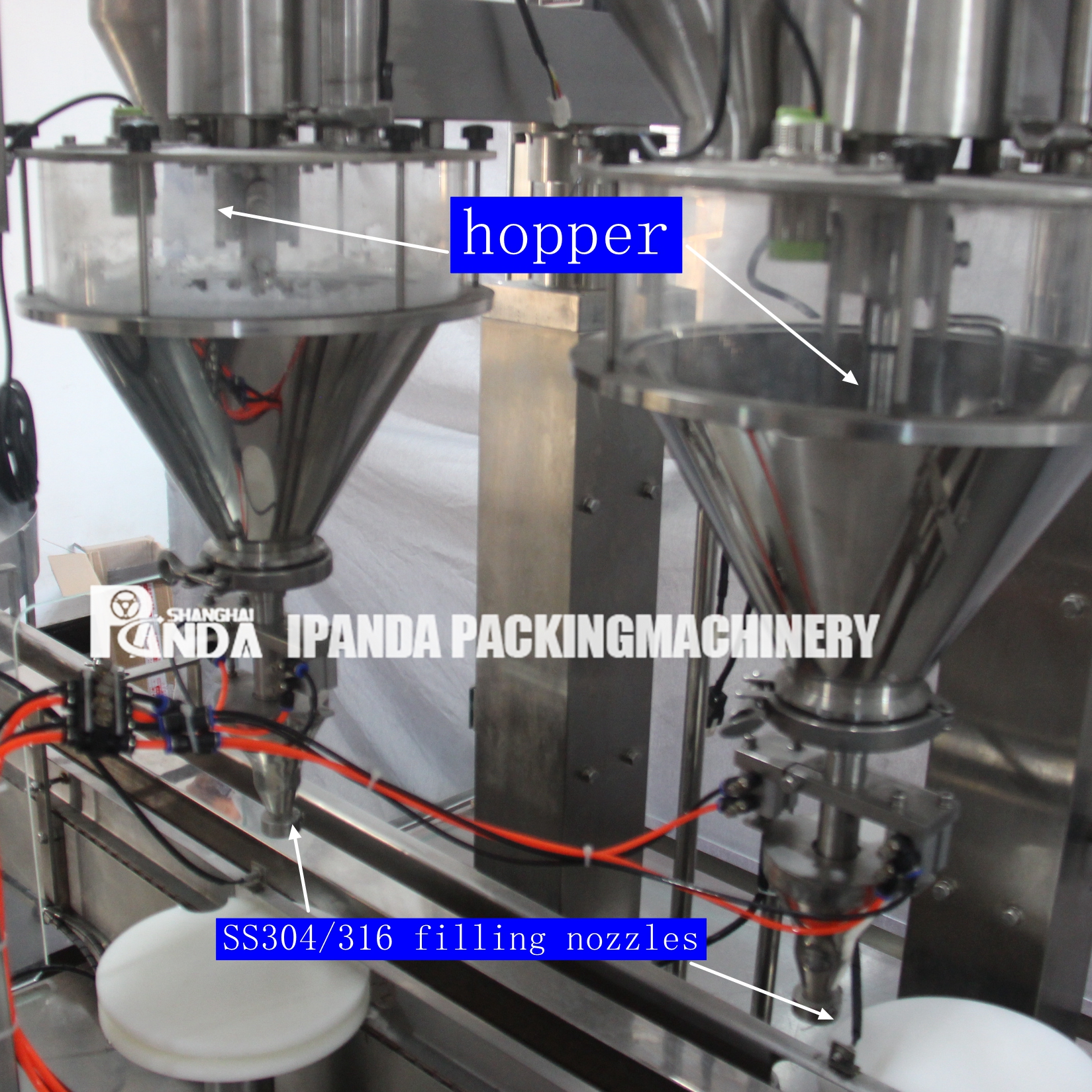

The Machine Details

Adopt PLC control

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction.

The size of bottles and cans can be adjusted in height, with large adjustment range, convenient and fast operation.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

The machine has a vibrating mechanism device, which can avoid the material with poor fluidity remaining in the hopper during filling, which will affect the filling accuracy.

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company’s equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of “Good quality , Good service, Good prestige”. We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Factory source Bottle Cover Sealing Machine - Automatic powder bottle filling machine/chemical powder filling line – Ipanda , The product will supply to all over the world, such as: Manchester, Montpellier, Bangkok, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!