factory customized Portable Filling Machine - Automatic Conical Centrifuge Reagent Test Tube Filling and Capping Machine – Ipanda

factory customized Portable Filling Machine - Automatic Conical Centrifuge Reagent Test Tube Filling and Capping Machine – Ipanda Detail:

Product Display

Overview

This machine is mainly used for automatic bottle unscrewing and capping (capping) of plastic bottle reagents. This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design; working table is protected by stainless steel material, and the whole machine meets GMP requirements. The transmission of this machine adopts mechanical transmission, the transmission is accurate and stable, there is no air source pollution and there are errors in the coordination of various mechanisms. When working, the noise is low, the loss is low, the work is stable, and the output is stable. It is especially suitable for small and medium batch production.

Parameter

| Accuracy | ±2% |

| Speed | 70-90 bottles/min |

| Upper cover mode | Manipulator the upper cover |

| Voltage | 220V/50Hz |

| Power | 4 KW |

| Dimensions | 2400mm×1200mm×1700mm |

| Weight | 580kg |

Features

Remark: In view of our products model different ,widely used in many industries ,in order to improve communication efficiency .so pls note the size weight and name of testing product before send us inquiry .so we can choose the suitable one for you ,send detail and quotation to your email .thank you for your understanding .

1.The oscillator is used for bottle management.and an independent sound insulation system is added to effectively reduce the interference of noise to users.

2.The peristaltic pump is used for filling,which can effectively avoid cross pollution.Our company adopts the independently developed program to control the imported servo motor drive, combined with the high-precision pump head (domestic or imported), and the accuracy can be controlled within plus or minus 2%.

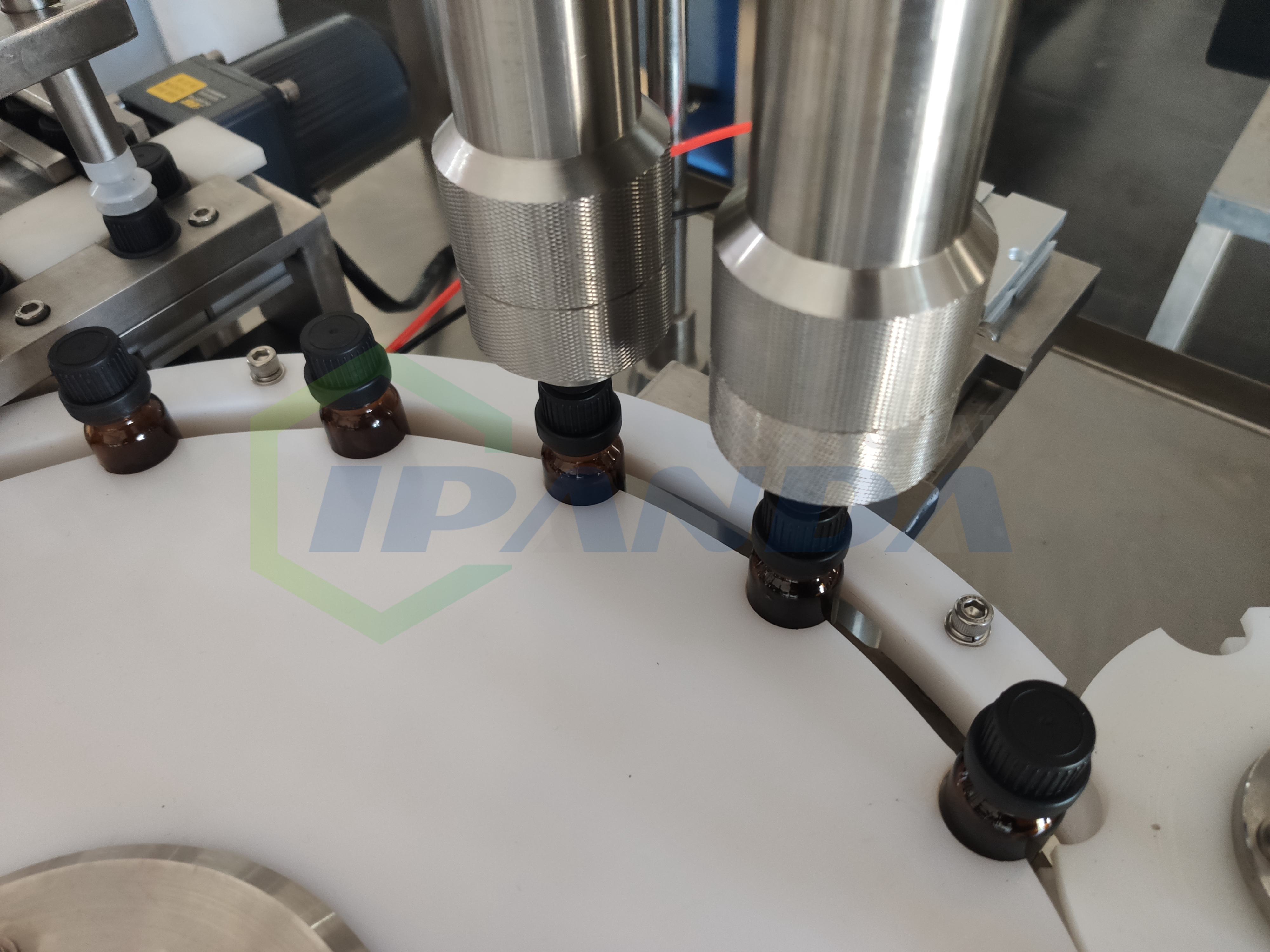

3.The vacuum manipulator is used for cover removal,Accurate positioning, not easy to fall off the cover. The cover is screwed with imported servo motor,and the torque is adjustable and controllable.

The Machine Details

This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design;

The high-precision peristaltic pump is used for filling, with high precision and no cross-contamination of materials; the structure of the pump adopts a quick-connect disassembly mechanism for easy cleaning

Put the inner plug-put the outside cap-screw the cap

Using a magnetic torque capping head, the capping torque is steplessly adjustable, with a constant torque capping function,This machine to correct the tilted cap, not to damage the cap, and the sealing is tight and reliable;

Cap vibrating plate used to arrange cap automatically

All action is controlled by PLC and Touch screen. The surface of machine is SUS304, material contacted with liquid is 316L stainless steel, can be connect with labeling machine.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

The talent team of Ipanda Intelligent Machinery Gathers product experts,sales experts and after-sales service staffs,and upholds the business philosophy of “High performance, Good service,Good prestige”.Our engineers are responsible and professional with more than 15 years experience in the industry.We will according to your product samples and filling material return the real effect of packing Until the machine work well ,we will not ship it to your side.Aimed at offering high level products to our customers, we adopt the SS304 material, reliable components for the products. And all the machines have reached CE standard. Overseas after-sales service is also available, our engineer has gone for many countries for service support. We are always striving to offer high quality machines and service to customers.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

FAQ

Q1. What’s the payment terms and trade terms for new customers?

A1: Payment terms: T/T, L/C, D/P, etc.

Trade terms: EXW, FOB, CIF.CFR etc.

Q2:What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A2:Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Q3: What’s the Minimum Order Quantity and warranty?

A3: MOQ: 1 set

Warranty: We offer you high quality machines with 12 months guarantee and offer technical support on time

Q4: Do you provide customized service?

A4: Yes, We have professional engineers whom have good experience in this industry for many years, they offer proposals include design machines, complete lines base on your project capacity, configuration requests, and others, make sure fulfill customer needs in market.

Q5.:Are you provide product metal parts and provide us technical guidance?

A5:Wearing parts,for example, motor belt,Disassembly tool(free) are what we could provide.And we can give you technical guidance.

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for factory customized Portable Filling Machine - Automatic Conical Centrifuge Reagent Test Tube Filling and Capping Machine – Ipanda , The product will supply to all over the world, such as: Greek, Belgium, Roman, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.