E-Liquid Filling Line Auto Cbd Oil Tincture Bottle Filling Capping Labeling Machine

Filling part of the machine can be used peristaltic pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. It is suitable for products of liquid such as essential oil, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent etc.The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

| Applied Bottle | 5-200 ml (can be customized ) |

| Productive Capacity | 20-40pcs/min 2 filling nozzles |

| 50-80pcs/min 4 filling nozzles | |

| Filling Tolerance | 0-2% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ,customize |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

Touch screen can be showed in English,Spanish,Rassina,Italian and others language,can be customized according to your requirement.

1. Filling part metering peristaltic pump filling to ensure filling accuracy.

2.Filling part of the needle probe into the filling, to prevent liquid overflow, frothing, etc., filling needles made of 316L.

3. Gasser disc using the positioning stopper, and modified into new pneumatic suction plug, boom, put the plug than conventional pneumatic corking yield, will not damage the inner plug, improve the passing rate.

4. Stamped part is stamped disc positioned to ensure precision stamped, and with sensors, no less than a bottle cap.

5. Capping part transverse torque capping, capping adjustable intensity, auto-skid device, not galling bottle; bottle not turn with the turntable will not scratch the bottle, effective protection of the beautiful packaging materials and equipment hand wheel adjustment devices (including the position of the display), adjust the height of different aspects of production specifications.

We adopt SS304 Filling nozzles and food grade slicone tube

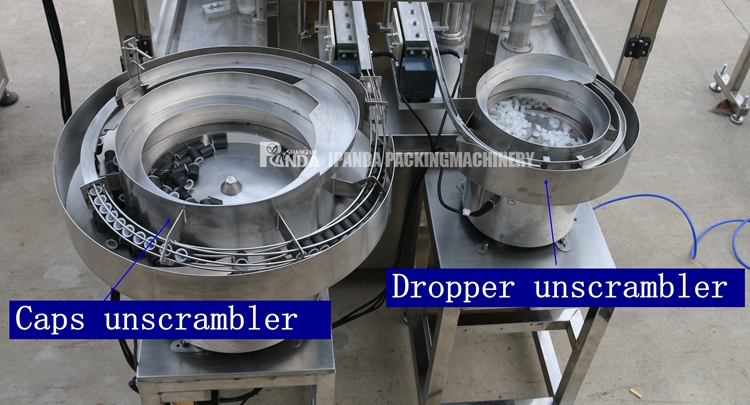

Inserting dropper-putting cap

Capping station

Adopt magnetic torque screwing capping

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs