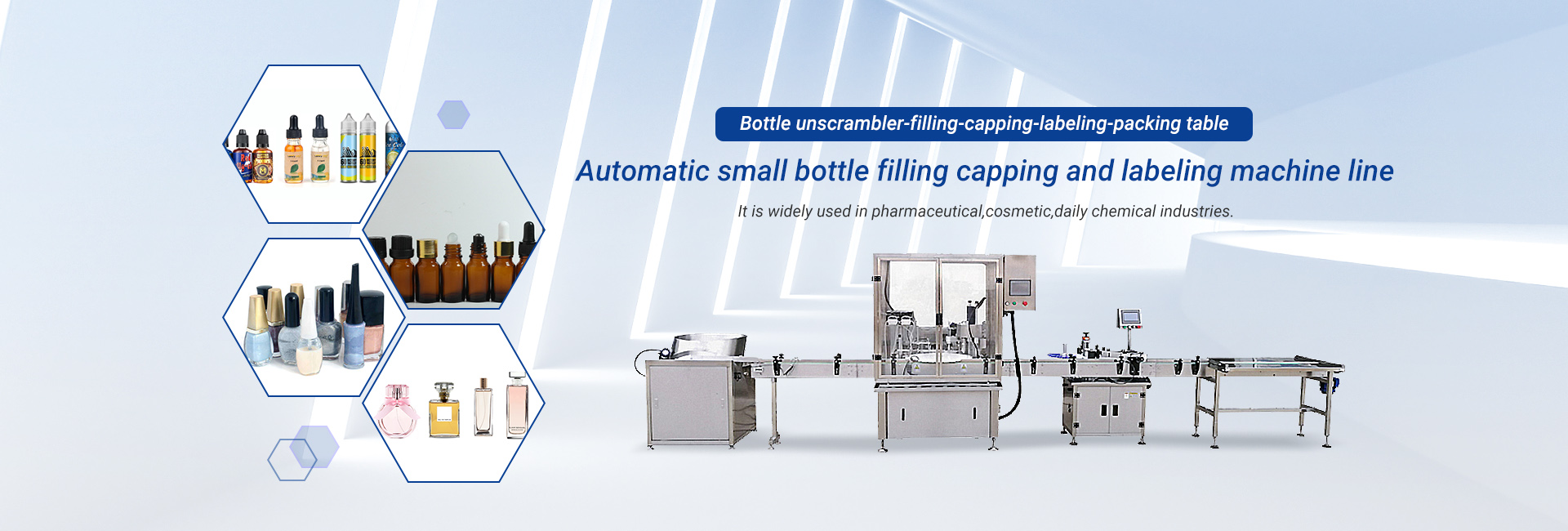

Customized Fully Automatic Eye Drop Liquid Filling Machine

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

| Main parameter of the machine | |||

| Name | Filling capping machine | Filling volume | 5-250ml,can be customized |

| Net weight | 550KG | Filling heads | 1-4 heads,can be customized |

| Bottle diameter | Can be customized | Filling speed | 1000-2000BPH,can be customized |

| Bottle height | Can be customized | Voltage | 220V,380V ,50/60GZ |

| Filling accuracy | ±1ml | Power | 1.2KW |

| Bottle material | Glass ,plastic bottle | Working pressure | 0.6-0.8MP |

| Filling material | Eye drop,e-liquid,cbd oil | Air consumption | 700L per hour |

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage.

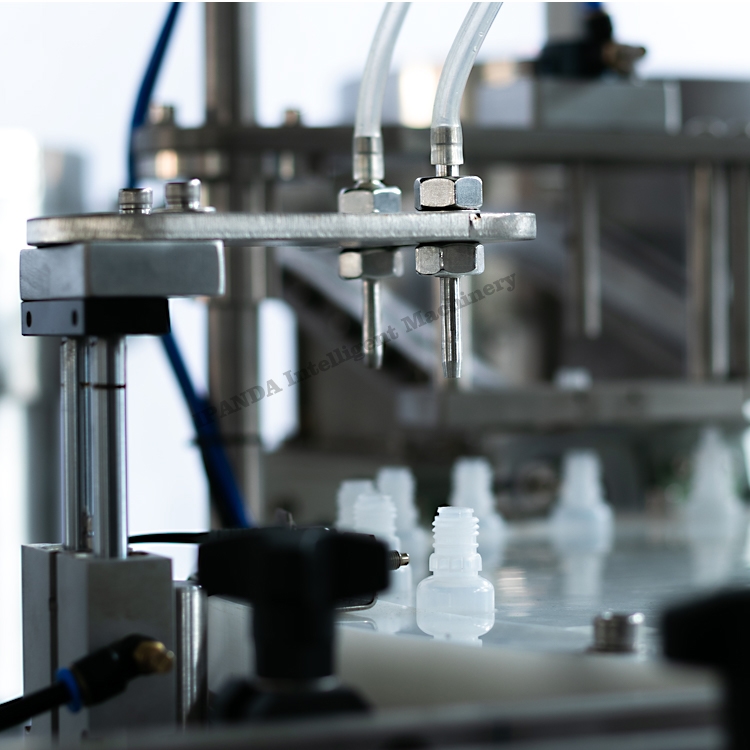

2. Peristaltic pump filling, measuring precision, convenient manipulation.

3. Filling system has function of suck back, avoid liquid leak through.

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping.

5. Filling nozzle is made by 316 stainless steel, machine body is made by 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

Adopt SS3004 filling nozzles and food grade Silicone tube.It's meet CE Standard.

Adopt Peristaltic pump: It's suitable for fluid filling.

Adopt Cap Unscrambler, it's customized according to your caps and droppers.

Capping part: Put the inner plug-put the cap-screw the caps.

Adopt magnetic torque screwing capping: sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs

FAQ:

Q:How can I get a Manufacturer automatic filling machine from you?

Just send us inquiry through this web page is ok. I will reply your any question within in 3 hours.

Q:Can your company able to offer 1 years gurantee?

Yes it's no problem for our company. During the warranty, if you need any spare parts, we will delivery it to you in DHL for free.

Q:Do you offer a free set of replacement parts for parts that commonly wear out quickly?

All spare parts are always avaliable for delivery. Above 90% spare parts are made by ourselves. Because we have our own processing center, so we can supply at anytime.

Q:What is the whole production line?Can i connect labeling machine,bottle feeder with filling machine in whole line?

I do not know how many meters of conveyors are involved so can not determine the over-all size of the line with all of its components.

We can help you match pipe and pump to transfer material form raw material tank to filling directly., so it can be totally auatomaticlly.We will design and make a layout plan according to customer's factory floor plan.