Customize Accepted Automatic 4 Nozzles Eliquid and Eye Drop Filling Machine

Adopt SS304 filling nozzles and food grade Silicone tube.It's meet CE Standard.

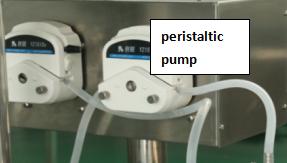

Adopt Peristaltic pump:

It's suitable for fluid filling.

Capping part:

Put the inner plug-put the cap-screw the caps.

Capping station

Adopt magnetic torque screwing capping

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs

Adopt Peristaltic pump,It’s suitable for fruid liquid filling.

ABOUT

COMPANY OVERVIEW

Growing Your Skills

Providing Best Talent Solution For

We Have More Than 20+ Years Practical Experience in Agency

- Dedication to Research & Development

- Experienced Management

- Better understanding of Customer requirement

- One Stop solution provider with Broad Range Offering

- We can supply OEM&ODM design

- Continuous Improvement with Innovation

Q1: What is your company's main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.