Chinese wholesale Toothpaste Packaging Machine - Overflow System Filling Machine for Fluency Liquid – Ipanda

Chinese wholesale Toothpaste Packaging Machine - Overflow System Filling Machine for Fluency Liquid – Ipanda Detail:

Product Display

Overview

The overflow filling machine can be customized according to user needs-to make multiple filling heads, the material contact surface is made of high-quality stainless steel, PLC control, touch screen to set the filling volume and parameters, simple and convenient operation, constant pressure timing, liquid Adjustable position, solenoid valve filling, good performance, high precision, no splashing, no foam, suitable for quantitative filling with low viscosity

Parameter

| Name | Automatic Overflow Filling Machine |

| Filling Nozzles | 2-16 nozzles, or customized |

| Power | 0.75KW-2.5KW |

| Applied bottle range | 100-1000ml, 1000ml-5000ml or customized |

| Filling Accuracy | ≤ ±0.5% |

| Filling speed | 500-4200 bottles/hour, 24b/min per 4 filling nozzles 1L |

| Dimension | 2200*1400*2300mm |

| Weight | 400kg |

| Power supply | 220V Single phase 50HZ 380V Three phase 50HZ |

Features

1.Man-machine Chinese interface, intelligent contact screen, human design, easy operation.

2. Imported filling valve, avoiding drop leaking, accurate filling quantity.

3. Program logic controller(PLC), easy for changing size or modifying parameters.

4. Pneumatic elements are all imported, stability and reliability.

5. Accurate liquid sensing, automatically adding liquid, ordinary pressure flow passage parameters

6. Solely and specially-designed whole lifting device, easy governing to meet the needs of all kindsof container packing

7. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

8. Pneumatic executive control valve, high efficiency and safety. Each flow passage can be separately governed and cleaned.

9. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

10.The whole machine is designed according to requirements of GMP.

The Machine Details

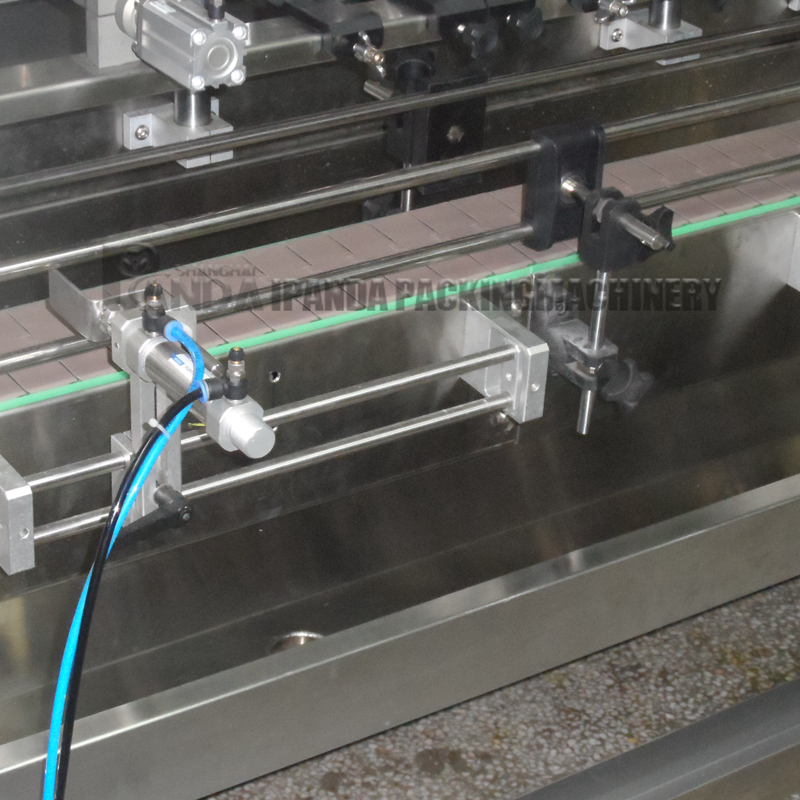

Filling nozzle:

Adopt 316 high quality stainless steel material . Filling nozzle size according to bottle volume and mouth to make .

Filling nozzle adopt bottle mouth diameter custom made , it adopt dive filling to make sure the filling material won’t have bubble.

Automatic material filling, 200L storage hopper is equipped with a liquid level device, when the material is lower than the liquid level device, it will automatically replenish the material.

Sensor positioning is accurate, automatic shutdown function, no bottle no filling, automatic shutdown function for accumulated bottles, sensitive response and long life

Chain conveyor belt

Stable operation, no pouring, abrasion resistance, sturdiness and durability

Adopt PLC control, Japanese PLC program control, intuitive man-machine interface, convenient operation, PLC control control, loading picture album

Material hopper:

The whole machine body adopt 304 stainless steel and slope design is adopted in the material box design .It is convenient for customers to change varieties, easy to clean, comply with the requirements of GMP.

Application

Application:

The material with lower viscosity, mouth wash, glassy water, water, toliet cleaner, diswashing liquid, liquid soap, detergent,solvents, alcohol, specialty chemicals, paint, inks, corrosive chemicals i.e. acids and bleach ect.

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Chinese wholesale Toothpaste Packaging Machine - Overflow System Filling Machine for Fluency Liquid – Ipanda , The product will supply to all over the world, such as: Germany, Liberia, Johannesburg, We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.