China wholesale Cap Sealing Machine - Peristaltic pump small volume bottle filling machine cosmetics equipment for perfume – Ipanda

China wholesale Cap Sealing Machine - Peristaltic pump small volume bottle filling machine cosmetics equipment for perfume – Ipanda Detail:

Product Display

Overview

Overview:

This machine is suitable for small dose liquid packaging production line in cosmetics,daily chemical and pharmaceutical industries etc, Can automaticlly complete filling, plug, screw cap,rolling cap, capping, bottling and other process.The whole machine is made of SUS304 stainless steel and the same grade aluminum alloy treated by positive grade, never rust, accord with GMP standard.

Application:

The equipment is ideal for filling small volume bottles, we customize machine for different size and shape of bottles, both glass and plastic are OK. It is widely used in Cosmetics (essential oil,perfume, nail polish, eye drop etc) chemical (glass adhesive, sealant, white latex, etc.) industries etc.

Parameter

| Applied Bottle | 5-200ml customized |

| Productive Capacity | 30-100pcs/min |

| Filling Precision | 0-1% |

| Qualified stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V,50Hz/220V,50Hz (customized) |

| Power | 2.5KW |

| Net Weight | 600KG |

| Dimension | 2100(L)*1200(W)*1850(H)mm |

Features

1)Touch screen and PLC control system,easy to operate and control.

2)Peristaltic pump filling, accurate metering, no leakage of liquid.

3)No bottle, no filling / no plugging / no capping.

4)Robotic arm capping system, stable and high speed, low failure rate, prevent bottle cap damage.

5)Production speed can be adjusted.

6)Wide range of use, can be used to replace the mold for different bottles filling.

7)The main electrical components of this machine are all used by famous foreign brands.

8)The machine is made of 304 stainless steel material, easy to clean, and the machine meets the requirements of GMP.

The Machine Details

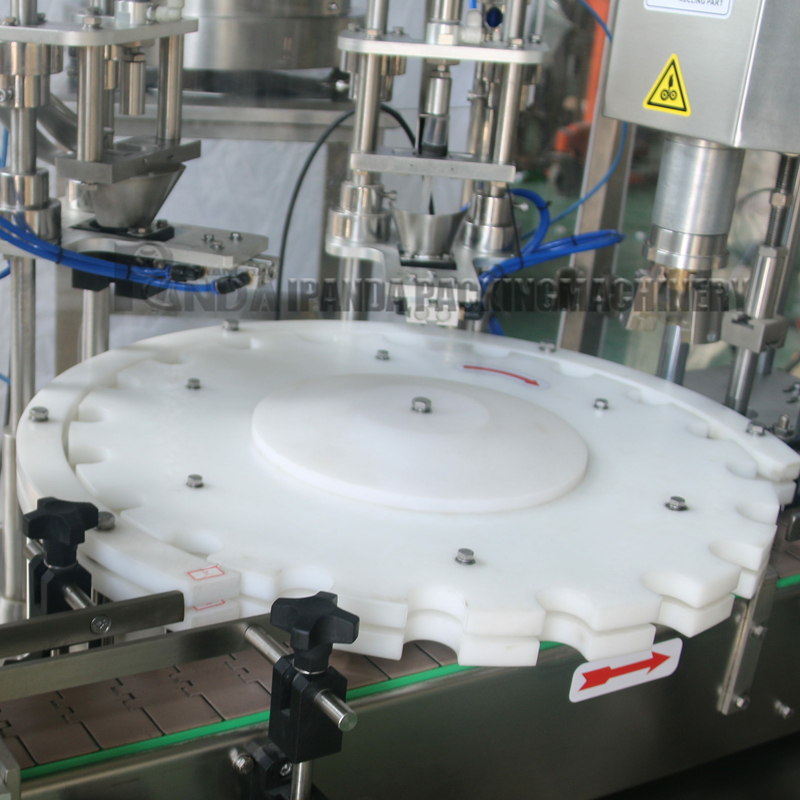

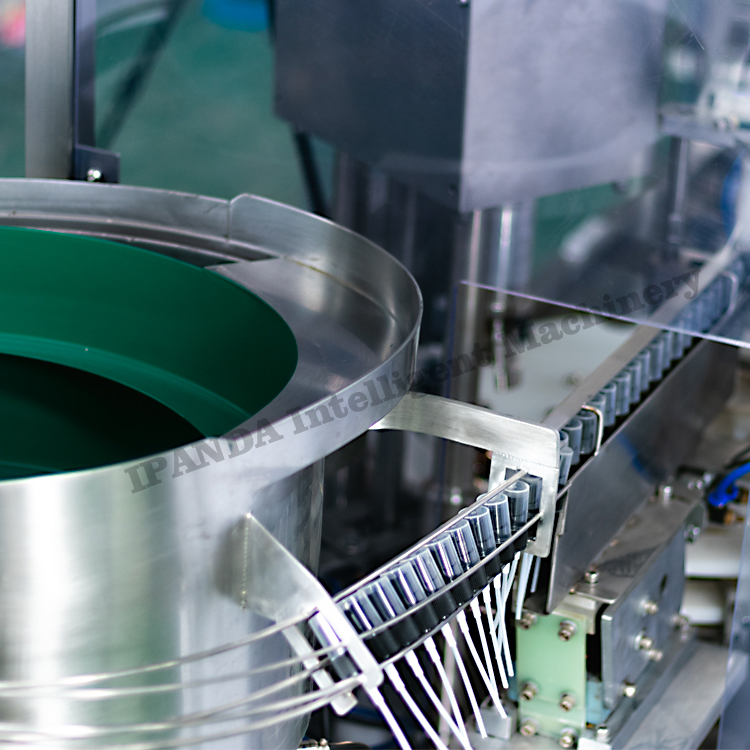

Rotary table, No bottle no filling, No cap auto stop, easy for trouble shooting, No air machine alarm, Multiple parameters setting for different caps.

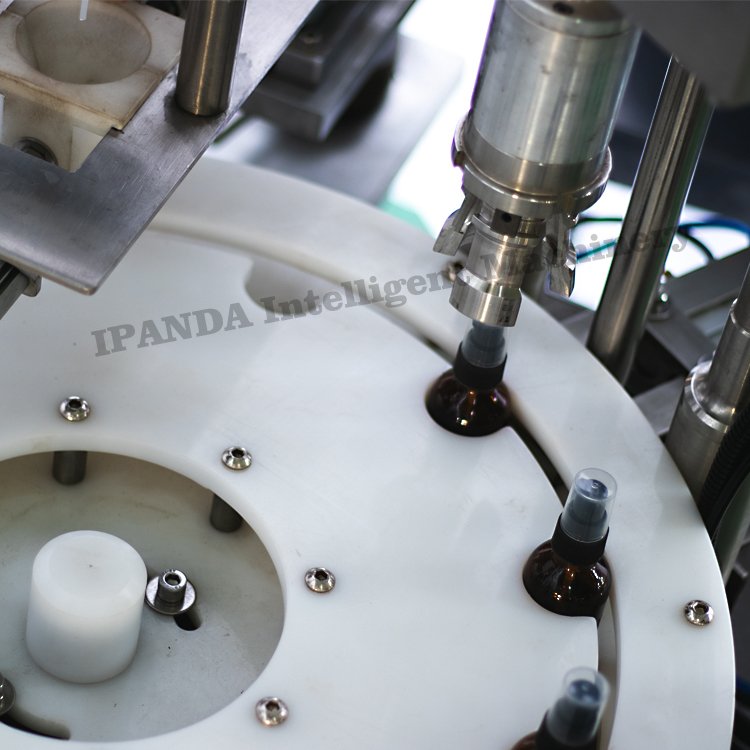

Filling system: lt can achieve automatic stopping when bottles are full, and automatic starting when bottles are lacked on the belt conveyor.

Adopt SS304 filling nozzles and food grade Silicone tube.It’s meet CE Standard.Filling nozzle dive into bottle to fill and rise slowly to prevent foaming.

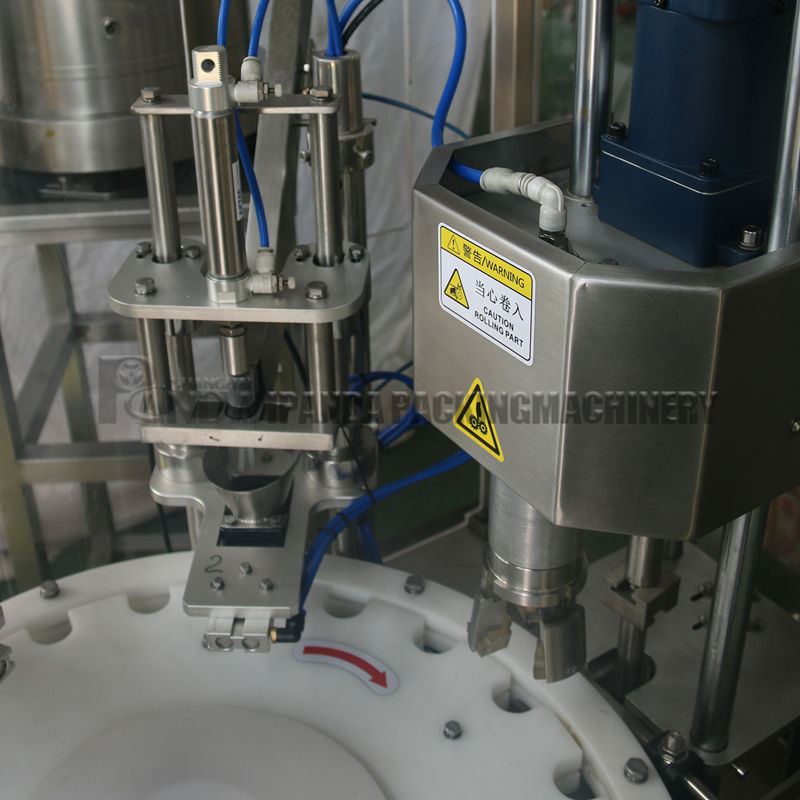

Capping station

Capping head all will customize according to customer different cap.

Adopt Cap Unscrambler, it’s customized according to your caps and inner plugs

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference

Product detail pictures:

Related Product Guide:

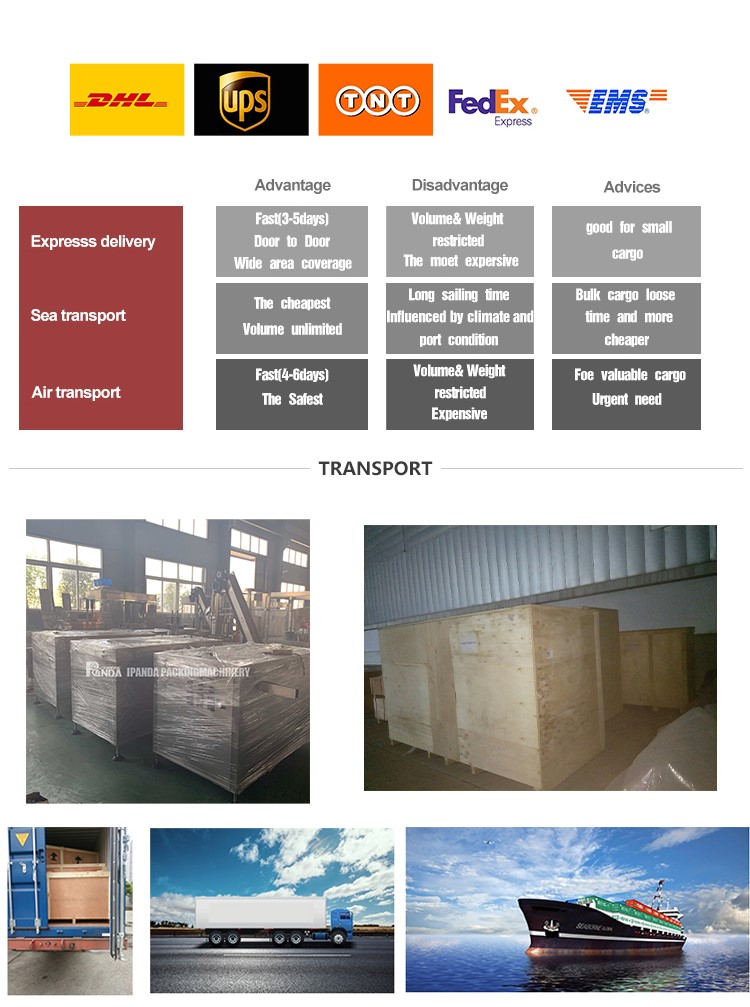

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for China wholesale Cap Sealing Machine - Peristaltic pump small volume bottle filling machine cosmetics equipment for perfume – Ipanda , The product will supply to all over the world, such as: New Delhi, Azerbaijan, Kuwait, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.