Bottom price Water Bottling Machine - Automatic Monoblock Vial Filling Capping Machine – Ipanda

Bottom price Water Bottling Machine - Automatic Monoblock Vial Filling Capping Machine – Ipanda Detail:

Product Display

Overview

Vial Liquid Filling and Stoppering Machine is suitable for the liquid filling and rubber stoppering of glass vials. Machine complete in pleasing matt finished stainless steel construction. The basic unit consists of turntable / unscrambler, SS Stat conveyor belt, Highly efficient and precision built S.S. 316 Syringes, non- toxic synthetic rubber tubing and easy reach compact panel.

The minimal distance between filling and stoppering units reduces the risk of contamination. The machines are designed for operation in a sterile area and for use under laminar flow protection. The un-scrambler itself has been redesigned to eliminate dead ends and difficult-to-clean spots.

Parameter

| Filling nozzle | 2 nozzles ( according to different speed can customize) |

| Capping head | 1 head ( according to different speed can customize) |

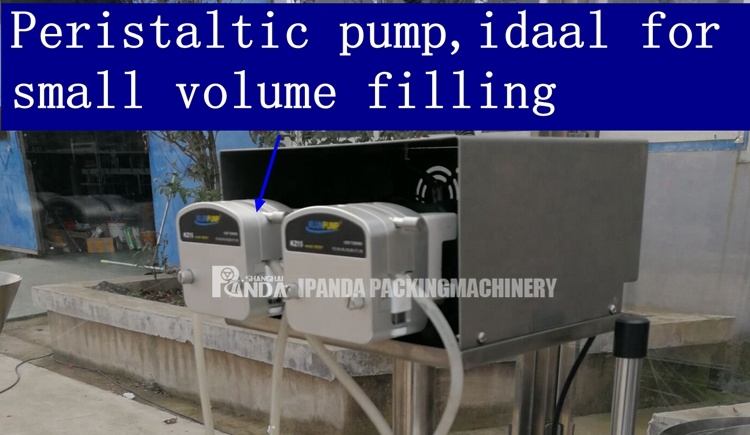

| Filling method | Peristaltic /piston pump (according to different material and filling volue can customize) |

| Capacity | 30 bottles/min ( 2 filling nozzles ,1 capping head) |

| Suitable bottle | Dropper bottle , plug bottle , rubber plug bottle , chubby gorilla bottle, vial. penicillin bottle,spray bottle (can customize to suitable to different type bottle and caps) |

| Filling material | E-liquid,vial,essential oil , spray liquid , oral liquid and so on (can customize) |

Features

1. It can be equipped with a protecting cover and a checking-drop installation according to client’s requirement.

2. It has the advantage of high-level automation degree, high-rate of finished products, good adaptability and stability which is popular among users.

3. It adopts the PLC program system to control, equipped with touch screen man-machine interface system, it’s convenient and easy to operate.

4. The filling machine is designed according to GMP requirements, which is made of stainless steel under the international of SUS316L, SUS304.

5. Monoblock system makes the machine small & delicate; adopting graduator to position bottles, it’s much more stable, easier to change & adjust for bottles of different sizes.

6. No bottle, no filling. This machine is simple operation, saving merits of human, not consumption field, etc.

Working Process

The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided.

The Machine Details

1)This is filling pipes, it is high quality imported pipes.There are the valves on the pipe, it will suck liquid back after once filling. So filling nozzles will not leakage.

2) The multi roller structure of our peristaltic pump further improves the stability and non impact of filling and makes the liquid filling stable and not easy to blister. It is especially suitable for filling the liquid with high requirement.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Bottom price Water Bottling Machine - Automatic Monoblock Vial Filling Capping Machine – Ipanda , The product will supply to all over the world, such as: Norwegian, Jamaica, Juventus, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!