Automatic small bottle essential oil bottling machine 2 in 1 essential oil filling plugging capping machine

The machine is an auto-liquid filling devise which is composed of PLC, human-computer interface, and optoelectronic sensor and air-powered. Combined with filling, plug, capping and screwing in one unit. It has the advantages of high accuracy, stable performance and greater versatility under extreme operating conditions which enjoys a high prestige. It has been widely applied in areas of pharmaceuticals industry.

| Applied Bottle | 5-200 ml (can be customized ) |

| Productive Capacity | 20-40pcs/min 2 filling nozzles |

| 50-80pcs/min 4 filling nozzles | |

| Filling Tolerance | 0-2% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ,customize |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

1. Can connect with bottle feeding table, capping and labeling machine,effective cost / space saving.

2. It has intuitive and convenient operation, measuring accurate, positioning precision.

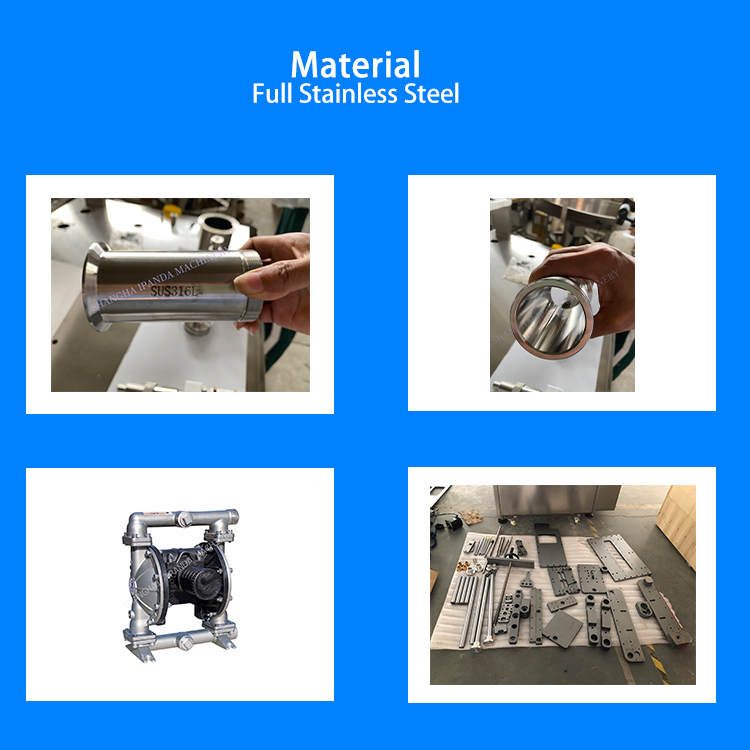

3. Fully in accordance with the GMP standard production and passed CE certification.

4. Siemens Touch screen/PLC+anti explosion pump+Servo motor control.

5. No bottle no filling.No bottle no capping.

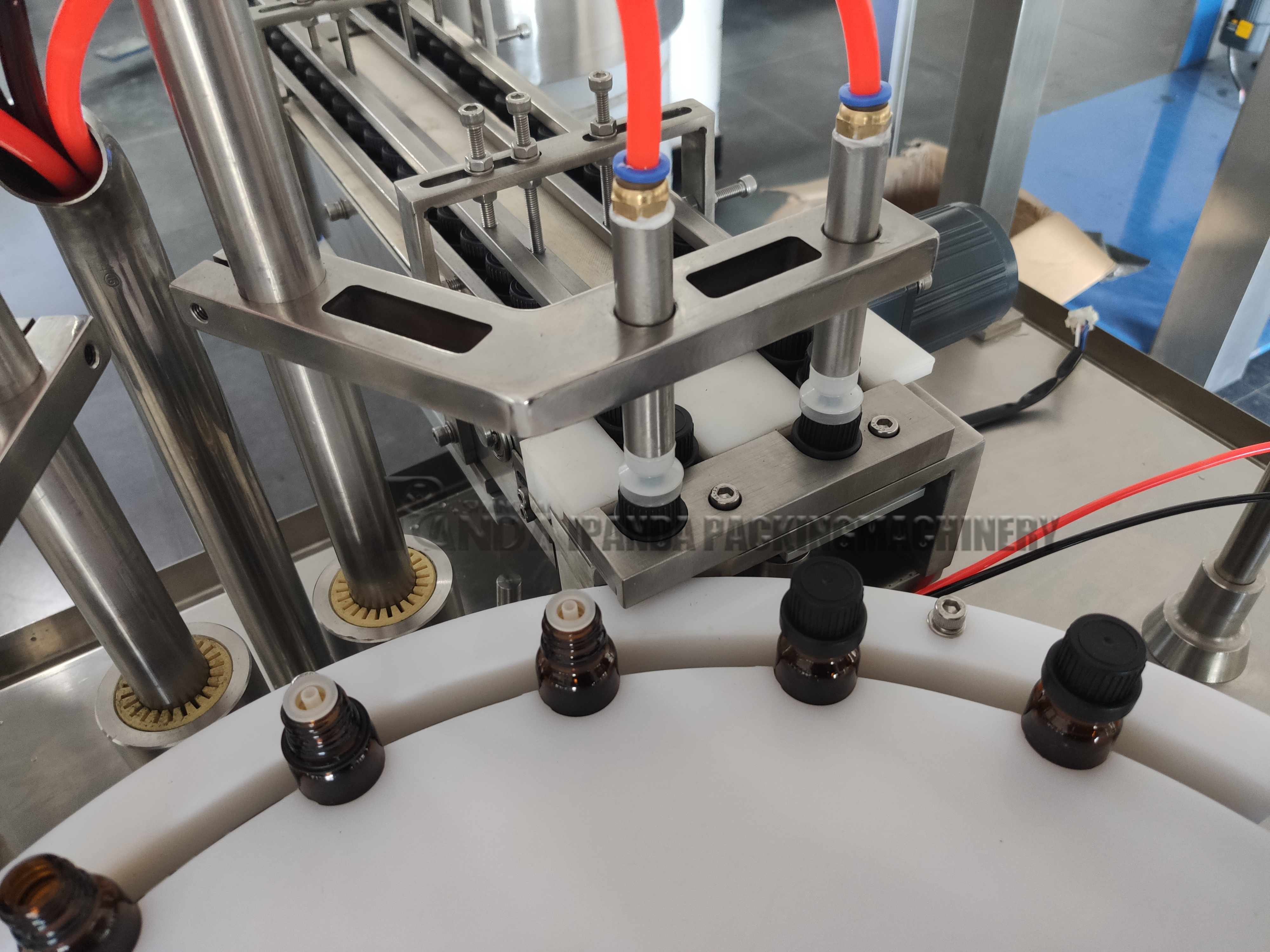

Filling part

Adopt SUS316L Filling nozzles and food grade silicon pipe

high precision. Filling zone protected by interlock guards for safety registration. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

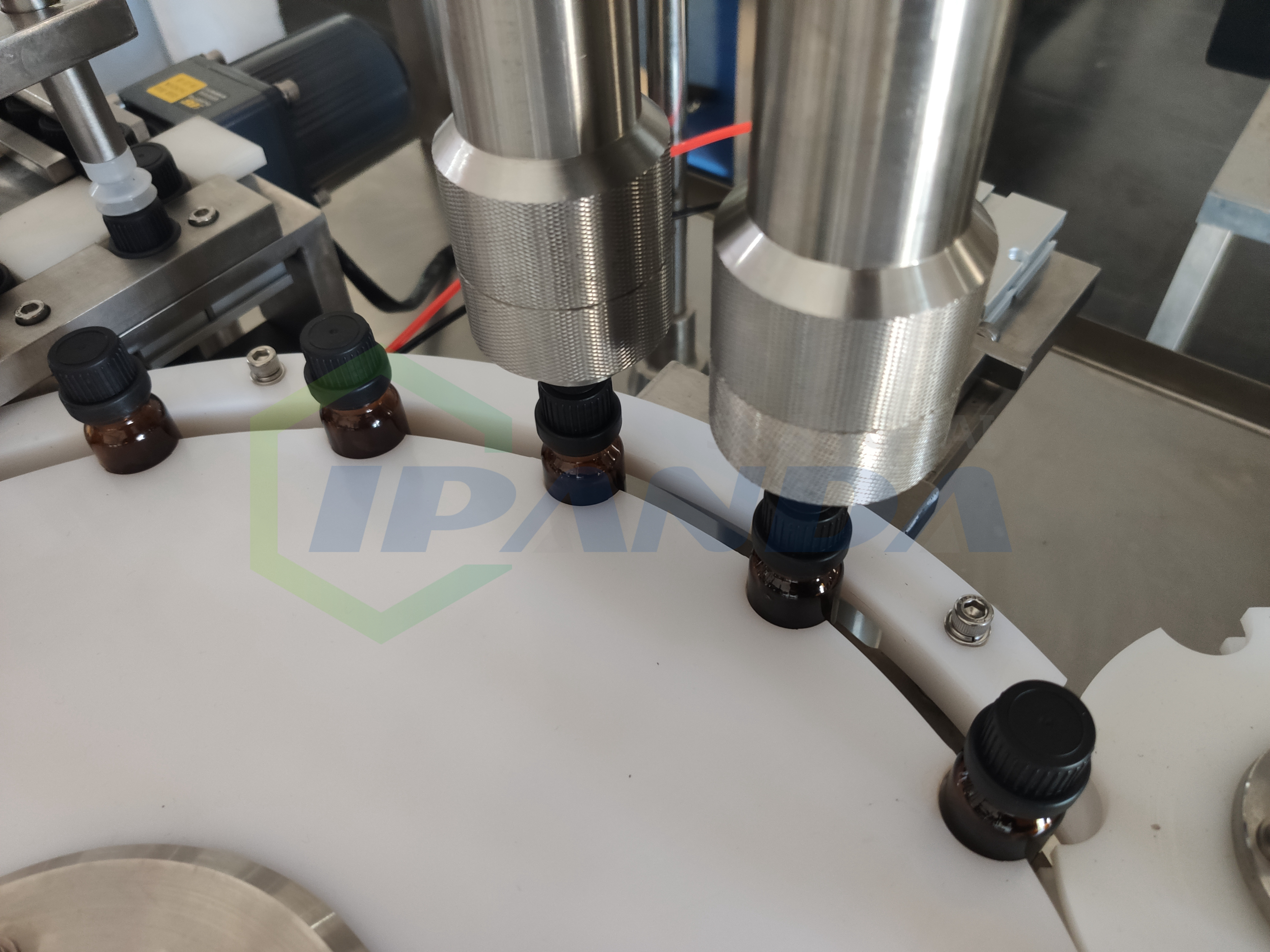

Capping Part: Inserting inner cap-putting cap-screw the cap