Automatic Shampoo Liquid Shower Gel Filling and Packing Line Machine

Automatic shampoo filling machine

The Piston filling machine is a high-tech product designed and developed by our company. It suits for different viscosity of water agent, semi-fluid and paste, it is widely used in the product filling of foodstuff, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry .

| Name | Liquid Filling Machine |

| Filling nozzle number | 2/4/6/8/12(can be customized) |

| Filling volume | 100-1000ml(can be customized) |

| Filling speed | 15-100bottles/min |

| Filling accuracy | 0 to 1% |

| Total power | 3.2KW |

| Power supply | 1ph .220v 50/60Hz |

| Machine size | L2500*W1500*H1800mm(customized) |

| Net weight | 600KG(customized) |

1. Automactic liquid filling machine,Small size, reasonable design, easy operation, stable performance, low failure rate;

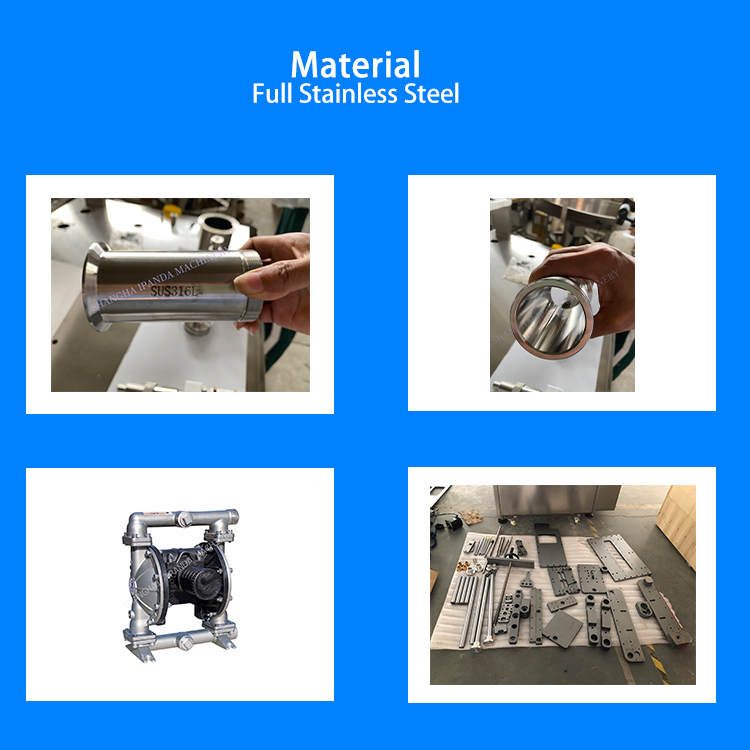

2. The whole machine is made of high-quality stainless steel. The 304/316L stainless steel material is used in contact with the material to meet the GMP hygienic requirements.

3. Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

4. There are filling volume adjustment handles, filling speed adjustment knobs, which can adjust the filling volume and filling speed arbitrarily; the filling precision is high;

5. According to the requirements of the environment, it can be changed to a full-air-explosion-proof type. It is completely de-energized and safer.

6. According to customer needs, customize the production of 4 heads, 6 heads, 8 heads and 12 heads.

7. Plastic bottles and glass bottles are customized according to customer requirements.

50ML-5L plastic bottles, glass bottles, round bottles, square bottles, hammer bottles are applicable

Hand sanitizer, shower gel, shampoo, disinfectant and other liquids, with corrosive liquids, paste are applicable.

Filling Nozzles

Various Filling Range

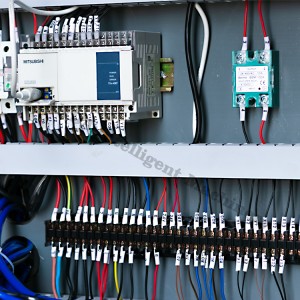

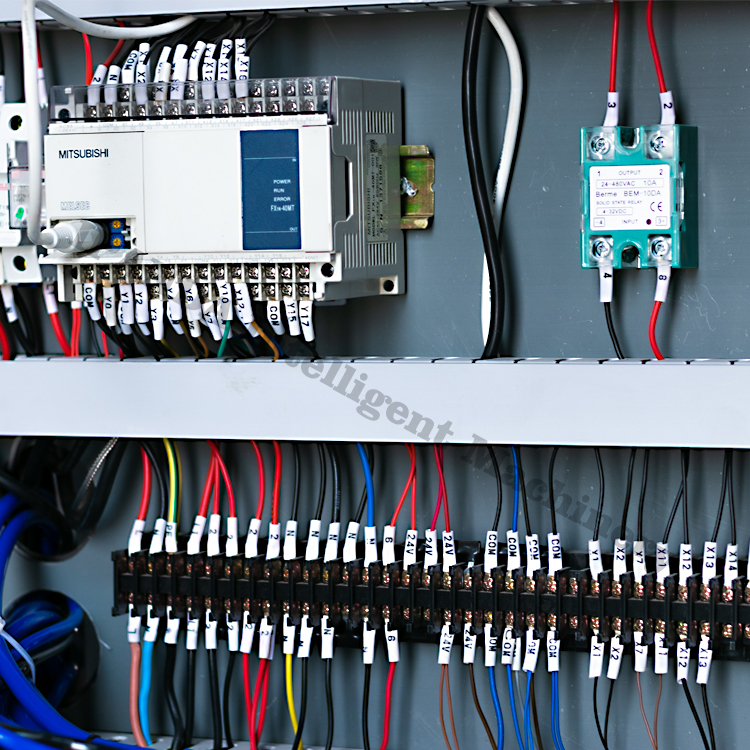

PLC Control System

We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement.