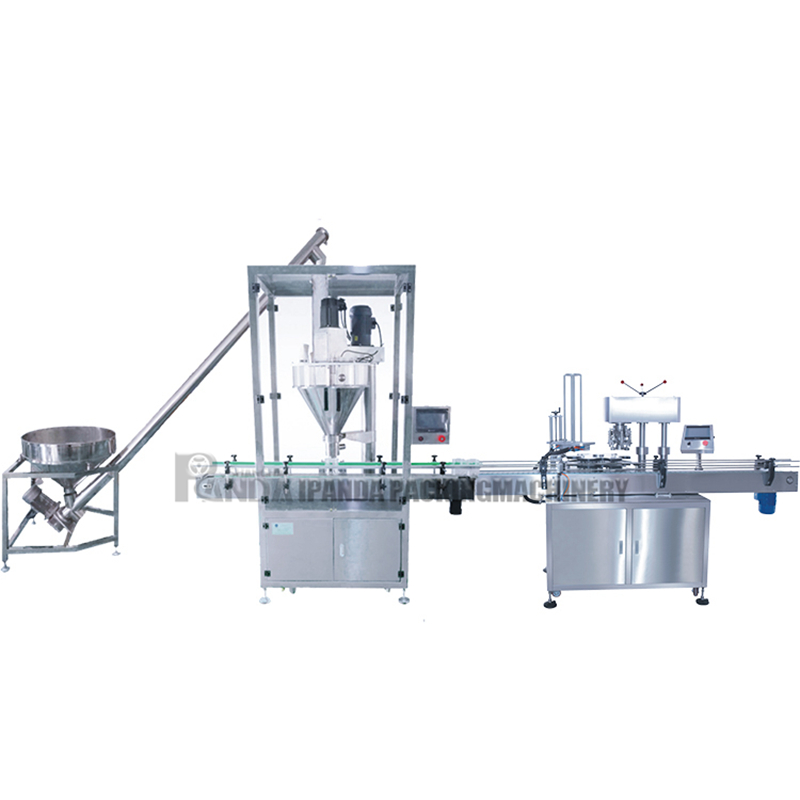

Automatic Powder Filling and Sealing Machine Series Products

This powder filling machine adopt auger to measure and fill powder and granular,with high filling speed and filling accuracy.It adopts feed screw by touch screen,which is suitable for all kind powder materials,such as:coffee,spice powder,white sugar ect.

This machine is used in dry powder, coffee powder, powder granular additives, sugar, monosodium glutamate, solid powder medicine, dyes, spices, medicine, chemical industry, food and other fields

| Auger Set | 1 | 1 |

| Container Diameter (mm) | 50-100 | 75-127 |

| Container Height (mm) | 100-200 | 100-200 |

| Packing Speed (cans/min) | 20-30 | 20-30 |

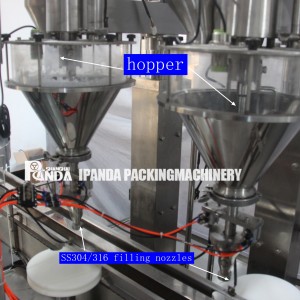

| Hopper Volume (L) | 26 | 50 |

| Power Requirement | AC 380V 3P+N+E 50HZ | AC 380V 3P+N+E 50HZ |

| Power Consumption(kW) | 2 | 2 |

| Compress Air Required (Mpa) | 0.6 | 0.6 |

| Compress Air Consumption(m3/min) |

0.2 | 0.2 |

1. Adopt a stepping motor and electronic weighing technology, the aircraft is slightly lower cost in comparison with the servo motor, and it is economical and practical.

2. Spiral cutting, light-control technology.

3. Specifications: The same machine within the 2-5000g adjustment and replacement of the keyboard under different specifications of material spiral continuously adjustable.

4. Scope: There is a certain fluidity of powder materials, containers (bags, cans)unlimited.

5. Materials due to changes in weight and material level of error correction can be automatically tracked.

6. Photoelectric switch control, only manual bagging, bag clean, easy to seal.

7. Screw feeder can be equipped with automatic feeding control.

Adopt PLC control

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction.

The size of bottles and cans can be adjusted in height, with large adjustment range, convenient and fast operation.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

The machine has a vibrating mechanism device, which can avoid the material with poor fluidity remaining in the hopper during filling, which will affect the filling accuracy.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.