Automatic oil filling production lines sunflower oil production line

1. This cooking oil filling machine has compact structure, flawless control system, and is convenient to operate with high grade automatism

2. All the parts of cooking oil filling machine contacting the media are made of high quality stainless steel, able to bear corrosion and easily rinsed

3. Adopts high precision and high speed piston filling valve so that the oil level is exact with loss, ensuring high quality filling

4. The capping head of sunflower oil production line has constant twisting movement, which ensures capping quality, without damaging caps

5. Adopts high efficiency cap tidying system, with flawless equipment for feeding caps and protecting

6. Needs only to change the pinwheel, bottle entering screw and arched board when changing bottle models, with simple and convenient operation oil production line

7. There is flawless equipment for overload protecting, which can protect effectively machine and operator safety

8. It adopts an electro motor with transducer adjusting speed, and is convenient to adjust productivity

It applies electronic measuring mode and special liquid component to realize low foam volumetric filling and can realize non-contact filling under all temperature condition. Other product :vegetable oil food oil ,edible oil.cooking oil,palm oil, engine oil, etc.

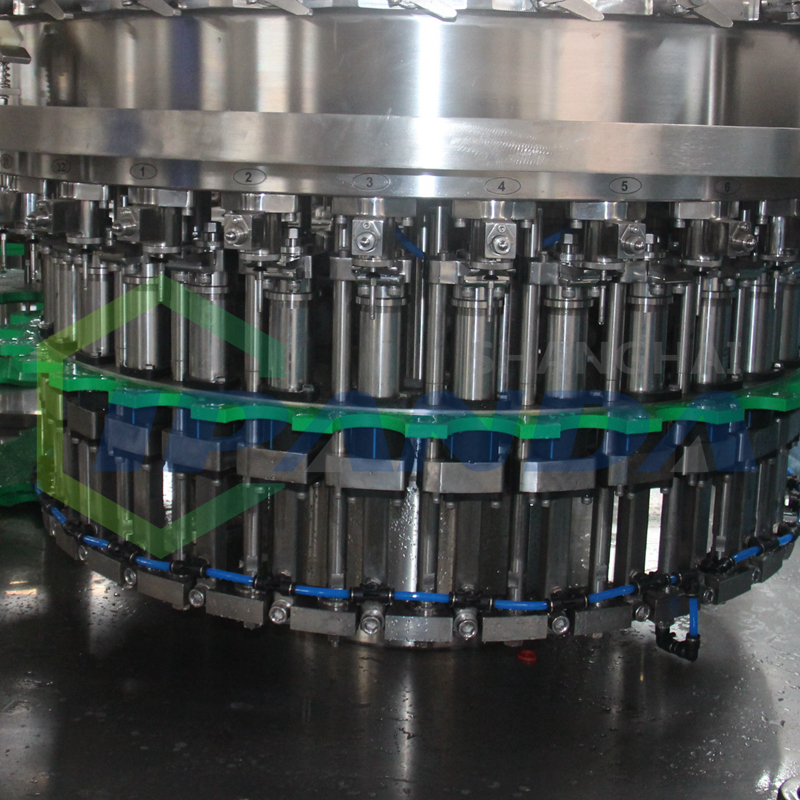

Filling part

<1> 304 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304 stainless steel contact parts and liquid tank, fine polish, easy to clean because of no death corner

<4> 304 stainless steel filling pump system

Capping part

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304 stainless steel construction

<3> Automatic stop when lack of bottle ,no bottle no capping

|

Technical Parameter |

||||||

| Model | Filling heads | Capping heads | Capacity(500ml)(B/H) | Motor power(kw) | Dimensions(mm) | Weight(kg) |

| 8-3 | 8 | 3 | 2000 | 1.9 | 1900*1420*2000 | 1500 |

| 12-6 | 12 | 6 | 4000 | 3.5 | 2450*1800*2400 | 2500 |

| 18-6 | 18 | 6 | 7000-8000 | 4.0 | 2650*1900*2400 | 3500 |

| 24-8 | 24 | 8 | 10000-12000 | 4.8 | 2900*2100*2400 | 4500 |

| 32-10 | 32 | 10 | 12000-15000 | 7.6 | 4100*2000*2400 | 6500 |