Automatic Ketchup/Tomato Sauce/Food Liquid Filling Capping Labeling Packaging Machine

The full automatic quantitative liquid filling machine is designed for saving time on adjusting and testing machine,it can filling liquid or paste accurately by entering a certain filling volume.The PLC control method makes it easy to operate,the high speed working efficiency is ideal for medium or large scale production.It can work with the automatic capping machine and labeling machine to form a complete production line and realize high speed packaging work.

|

Voltage |

220V 50-60HZ |

|

Filling Range |

5-100ml/10-300ml/50-500ml/100-1000ml/500-3000ml/ 1000-5000ml |

|

Filling Speed(base on oil) |

25~40 bottles/min |

|

Filling Heads |

2/4/6/8/10 heads |

|

Filling Accuracy |

≤1% |

|

Conveyor size |

2000*100mm(L*W) |

|

Size of filling nozzle |

OD15mm |

|

Size of air compressor connector |

Φ8mm |

|

Power of whole machine |

1500W |

|

Machine size |

2000*900*1900mm |

|

Gross weight/Net weight |

400KG |

1. Adopts world-famous brands of electrical and pneumatic components, low failure rate, reliable performance, long service life.

2. Material contact parts are made of stainless steel, easy to disassemble and assemble, easy to clean and meet the requirements of GMP.

3. Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

4. With no bottle no filling function, liquid level automatic control feeding.

5. Piston Seals with Tetrafluorine Technology improve the wear resistance of the piston seals (service life is 12 months or more) and have a good applicability to materials.

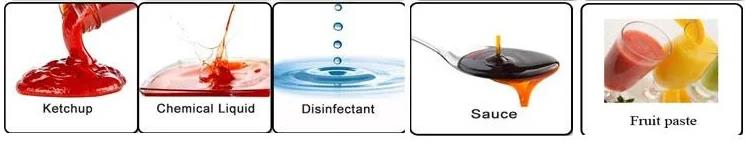

Food (olive oil, sesame paste, sauce, tomato paste, chili sauce,butter,honey etc.) Beverage( juice, concentrated juice). Cosmetics (cream, lotion,shampoo, shower gel etc) Daily chemical (dishwashing, toothpaste, shoe polish, moisturizer, lipstick, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricants, and plaster pastes for special industries The equipment is ideal for filling high-viscosity liquids, pastes, thick sauces, and liquids. we customize machine for different size and shape of bottles.both glass and plastic are OK.

Adopt SS304 or SUS316L filling nozzles

Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.