Automatic glass test tube pharmaceutical liquid reagent filling machine

This model is mainly applicable to the filling and capping of various tubular bottles that are easy to pour during operation. Automatically complete bottle loading, filling, capping, capping, bottle outlet, etc.

The inclined bucket silo is used for bottle management.The bottle mouth of the pipe is manually placed into the silo in an orderly manner in the same direction.The dial wheel automatically sends the pipe to the horizontal rotating vertical mechanism.and then into the main star disk.

| Accuracy | ±2% |

| Speed | 0-40 bottles/min |

| Upper cover | Manipulator takes off the upper cover |

| Voltage | 220V/50Hz |

| Power | 3 KW |

| Dimensions | 2500mm×1200mm×1700mm |

| Weight | 580kg |

* All electrical components arewell-known brands.

* Disc positioning filling, which is stable and reliable.

* High-precision cam indexer controlto reach precise positioning.

* It is made of SUS304 or316L stainless steel, which meets GMP requirements.

* Man-machine interface settingwith PLC control has intuitive and convenient operation

* Accurate loadingand automatic counting.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping.

This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design;

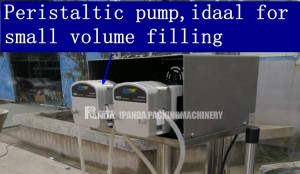

The high-precision peristaltic pump is used for filling, with high precision and no cross-contamination of materials; the structure of the pump adopts a quick-connect disassembly mechanism for easy cleaning

The swing arm is used to hook the upper cover, and the positioning is accurate;

Pneumatic control is adopted to clamp the screw cap, which will not cause wear to the shape of the bottle cap; The height and clamping force of the screw head are easy to adjust and control