Automatic Filling Machine Perfume/Eye drop/10ml Bottling Capping Labeling Machine

This filling machine can be divided into automatic bottles feeding (Also can use choose manual load bottle)automatic filling, automatic pump cap capping head, pre-capping head for regulate and tighten up pump cap head and automatic capping etc.

| Applied Bottle | 5-200ml customized |

| Productive Capacity | 30-100pcs/min |

| Filling Precision | 0-1% |

| Qualified stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V,50Hz/220V,50Hz (customized) |

| Power | 2.5KW |

| Net Weight | 600KG |

| Dimension | 2100(L)*1200(W)*1850(H)mm |

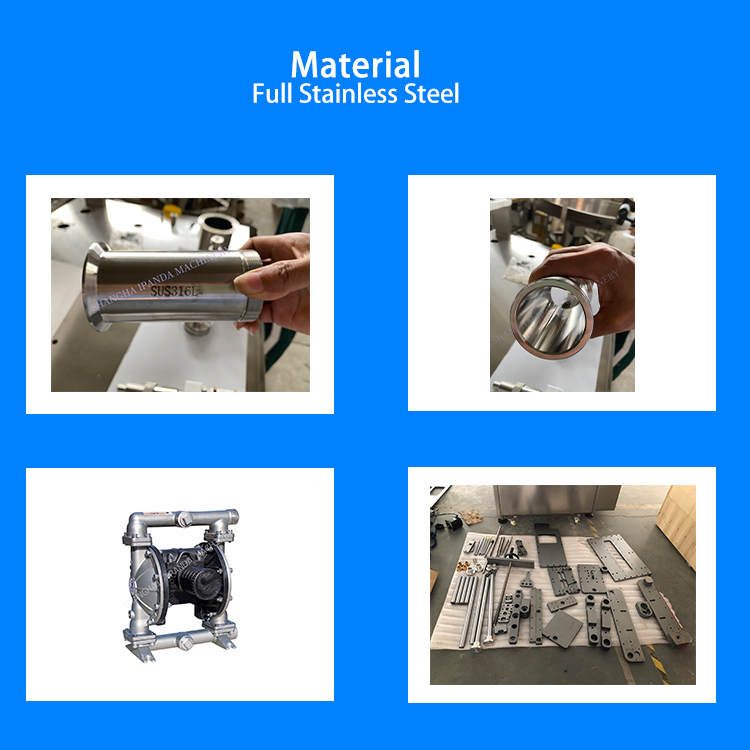

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

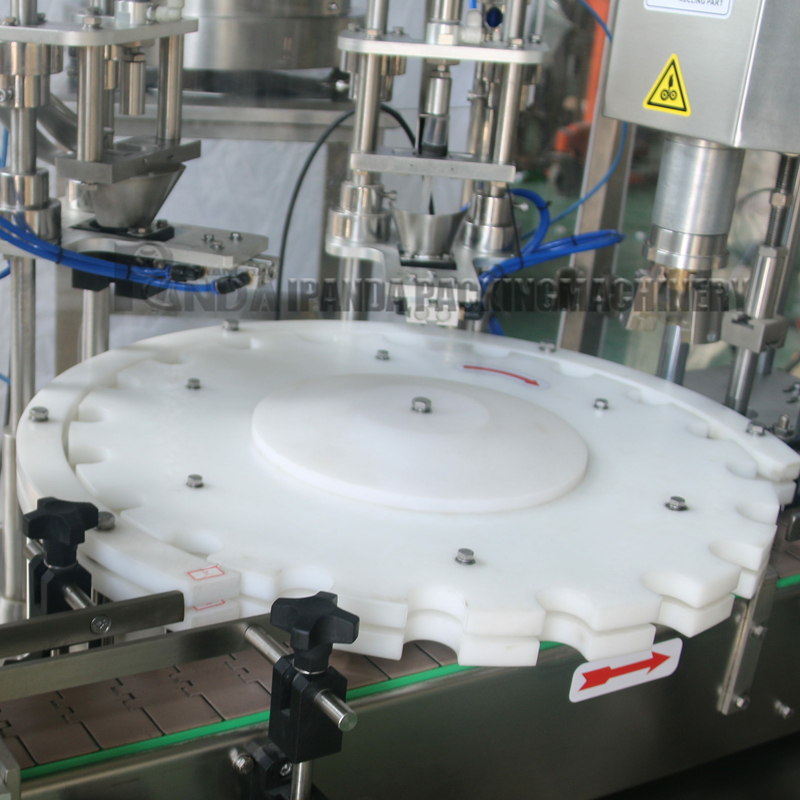

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

Rotary table, No bottle no filling, No cap auto stop, easy for trouble shooting, No air machine alarm, Multiple parameters setting for different caps.

Filling system: lt can achieve automatic stopping when bottles are full, and automatic starting when bottles are lacked on the belt conveyor.

Filling head: Our filling head have 2 jackets You can see the filling split connect with 2 pipes.The outside jacket connect with vacuum suction air pipe.The inner jacket connect with filling perfume material pipe.

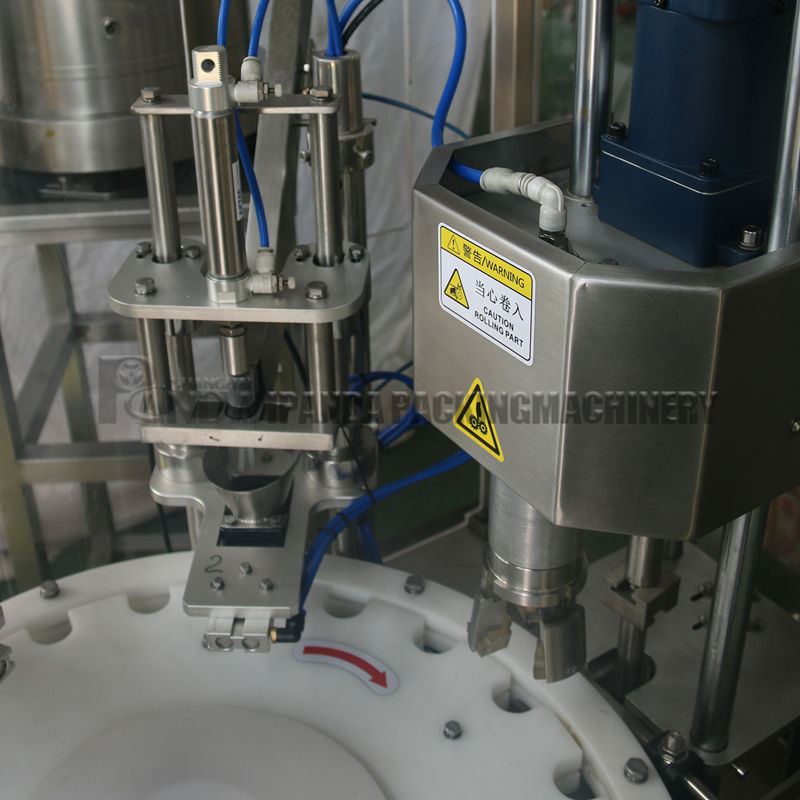

Capping station

Capping head all will customize according to customer different cap.

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs