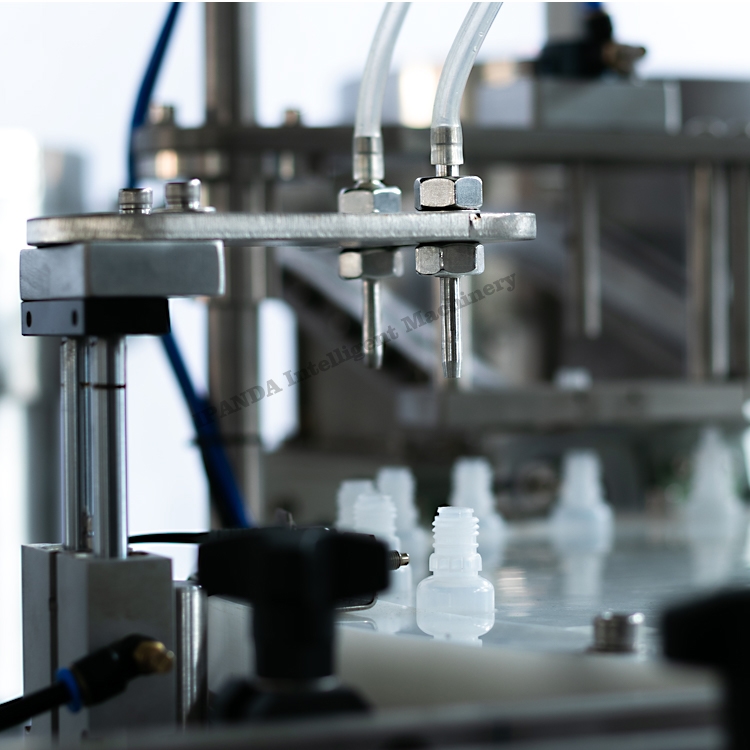

Automatic Eye Drop Filling And Capping Machine

This eye drops filling and capping machine is our traditional product, and as to customers’ needs, we had some innovation for this machine. The positioning & tracing filling are adopted for 1 / 2 / 4 nozzles filling & capping machine, and the productivity can satisfy the user. The pass rate is high. And as to customers’ requirement, the washing/ drying linkage production line or unit machine can be connected.

| Applied Bottle | 10-120ml |

| Productive Capacity | 30-100pcs/min |

| Filling Precision | 0-1% |

| Qualified stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V,50Hz/220V,50Hz (customized) |

| Power | 2.5KW |

| Net Weight | 600KG |

| Dimension | 2100(L)*1200(W)*1850(H)mm |

1. This filling and capping machine is multi-function monoblock machine with compact design..

2. This machine applies to foodstuff, pharmacy, cosmetic, chemical and pesticide industries.

4. The machine is controlled by PLC and touch screen.

5. It applies Peristaltic pump filling system.

6. Flexible for all kinds of capping heads, screw, press, alu. Roll.

7. It is ideal equipment for low-capacity requirement. It can tighten caps automatically.

8. All the parts which touch the material are made of high quality stainless steel, and the surface has been polished, no pollution to the surrounding.

Adopt SS3004 filling nozzles and food grade Silicone tube.It's meet CE Standard.

Adopt Peristaltic pump: It's suitable for fluid filling.

Adopt Cap Unscrambler, it's customized according to your caps and droppers.

Capping part: Put the inner plug-put the cap-screw the caps.

Adopt magnetic torque screwing capping: sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps