Automatic Eliquid Essential Oil Filling Capping Machines

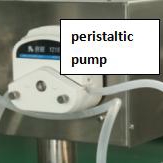

Filling part of the machine can be used 316L stainless steel peristaltic pump pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. It is suitable for products of liquid such as essential oil, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent etc.The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

|

Applicable specifications |

1ml-200mml or customized |

|

Production capacity |

30-40 Bottle/min or 60-80BPM |

|

Filling accuracy |

≤±1% |

|

Power supply |

220V/50Hz |

|

Rotating (rolling) cover rate |

≥99% |

|

Power |

2.0 kw |

|

Machine net weight |

650 kg |

|

Dimensions |

2440*1700*1800mm |

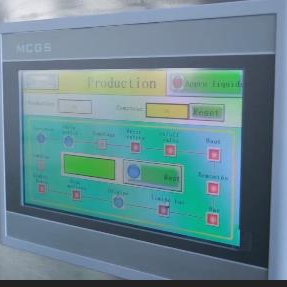

1.Adopt human-computer interface,PLC controller,easy to operate

2.Use frequency converting control,easy to adjust the filling speed,automatic count

3.Automatic stop,no bottle no filling.

4.Round turn table for positioning filling,stable and reliable .

5.High precision CAM indexing gage control.

The material will be pumped through the reciprocating piston filling machine under the action of the cylinder. The cylinder of the pumping stroke is adjusted by a signal valve to adjust the required filling volume to achieve precise filling results.

The detail pictures:

We adopt SS304 Filling nozzles and food grade slicone tube

Cap sorter is customized for your cap

It unscramble the caps and convey to capping part of the machine.

Inserting dropper-putting cap

Adopt magnetic torque screwing capping

Adopt Peristaltic pump,It’s suitable for fruid liquid filling.

Adopt PLC control,touch bottle operation, simple and convenient operation;