Automatic cream tube filling sealing machine

Main parts :

|

Tube Material |

Plastic tube,laminated tube,Aluminum tube |

|

Ultrasonic Power |

2000W |

|

Ultrasonic Frequency |

20KHz |

|

Power Supply |

AC 220V, 50/60Hz |

|

Delay Time/Weld Time/Seal Time |

0.01-9.99S |

|

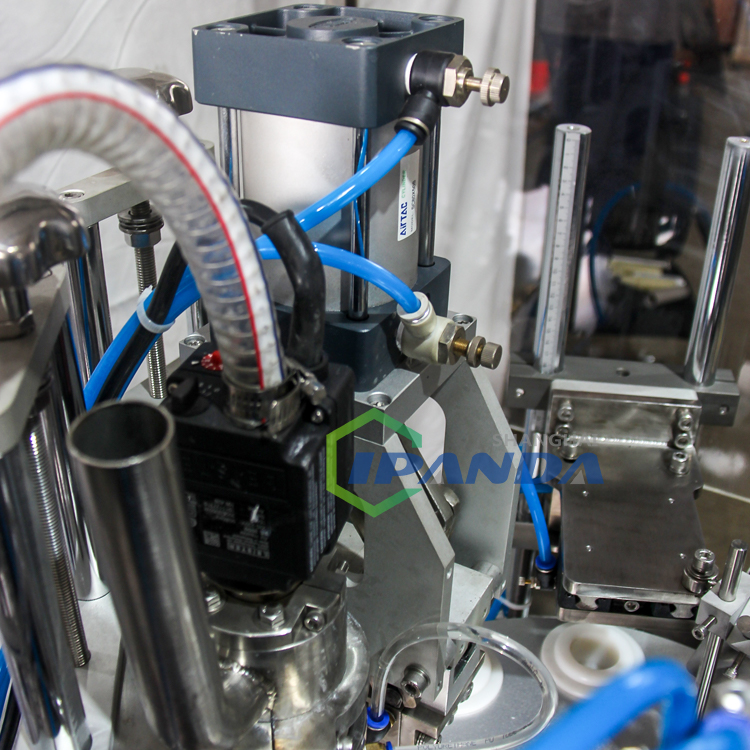

Driven Mode |

Pneumatic |

|

Stroke |

75MM |

|

Working Pressure |

0.4-0.7Mpa |

|

Tube Diameter Range |

Φ5mm-Φ50mm |

|

Tube Height Range |

50-250mm(customizable) |

|

Filling Volume Range |

5-250ml(Adjustable) |

|

Filling Accuracy |

≤±1% |

|

Working Stations |

10 |

|

Hopper Volume |

30L |

|

Capacity |

30-60 tubes/min |

|

Packing Dimension |

L*W*H 1310*1050*1760 mm |

|

Gross |

440 KGS |

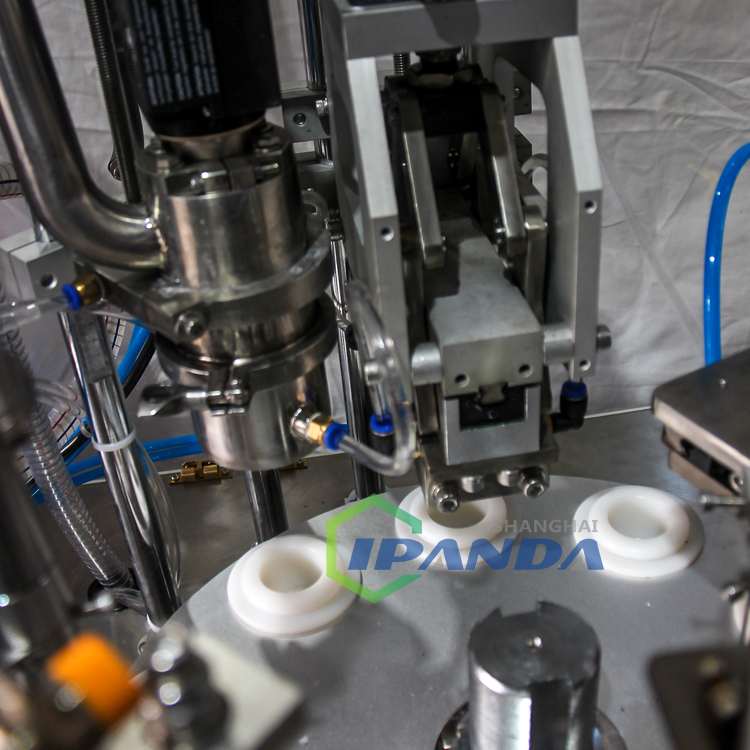

(1)With 12 stations and matching with manipulator, the machine is able to meet different type of tail folding, sealing requirements of Alu tube. It is a multi-purpose machine.

(2)Tube feeding, eye marking, tube interior cleaning (optional), material filling, sealing (tail folding), batch number printing, finished products discharging can be performed automatically (the whole procedure).

(3)Servo control makes it precise and convenient to adjust the filling amount by touch screen.

(4)According to the different length of the tube, height of tube chamber can be adjusted easily by motor. With external reversal feeding system, makes tube charging more convenient and tidy.

(5)The mechanical linkage photo sensor precision tolerance is less than 0.2mm. The chromatic aberration scope between tube and eye mark is reduced.

(6)Photo-electronic, electric, pneumatic integrative control is applied with the machine. No tube, no filling. It gives an alarm.when low pressure occurs. The machine stops automatically if tube error or open the safety door.

(7)Three-layer jacket instant heater with inside air heating, it won't damage the pattern on outer wall of tube and achieves firm and beautiful sealing effect.

The mechanical linkage photo sensor precision tolerance is less than 0.2mm. reduce the chromatic aberration scope between tube and eye mark.