Automatic Bag In Box Filling Machine

The bag-in-box filling machine adopts the flow meter measurement method, the filling precision is high, and the setting and adjusting the filling amount is very intuitive and convenient; the machine has novel design, reasonable and compact structure, and can automatically complete the capping, quantitative filling, vacuuming, Pressing and other processes.

|

Filling range |

1L-25L |

|

Filling accuracy |

±1% |

|

Filling speed |

200-220bags/hour (when filling 3L) |

|

180-200bags/hour (when 5L) |

|

|

Liquid material inlet pressure |

≤ 0.3-0.35Mpa |

|

Power |

≤ 0.38 KW |

|

Power supply voltage |

AC220V/50Hz ±10% |

|

Air consumption |

0.3M3/Min |

|

Working pressure |

0.4-0.6Mpa |

It can be widely used in bag-in-box filling applications for such liquid materials as drinking water, wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.

1) The outer casing and the frame are mainly made of high quality stainless steel, and the appearance is beautiful; the pipe in contact with the material is made of 304 stainless steel and food grade plastic pipe, which meets the food hygiene requirements.

2)can automatically complete the process of pulling the faucet, vacuuming, quantitative filling, pressing the faucet, etc., with a high degree of automation.

3)using flow meter measurement method, filling accuracy is high, speed is fast; filling volume setting and adjustment is convenient and quick.

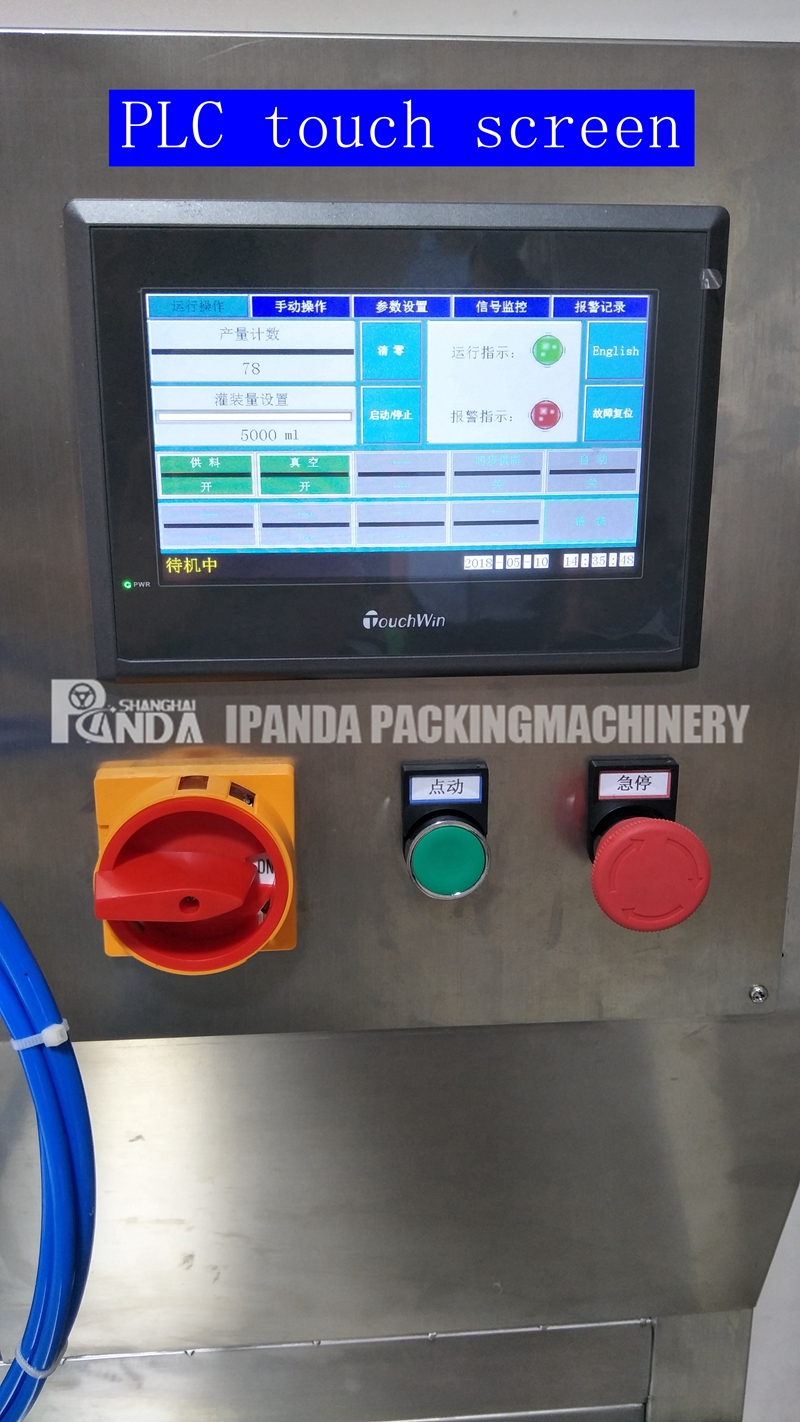

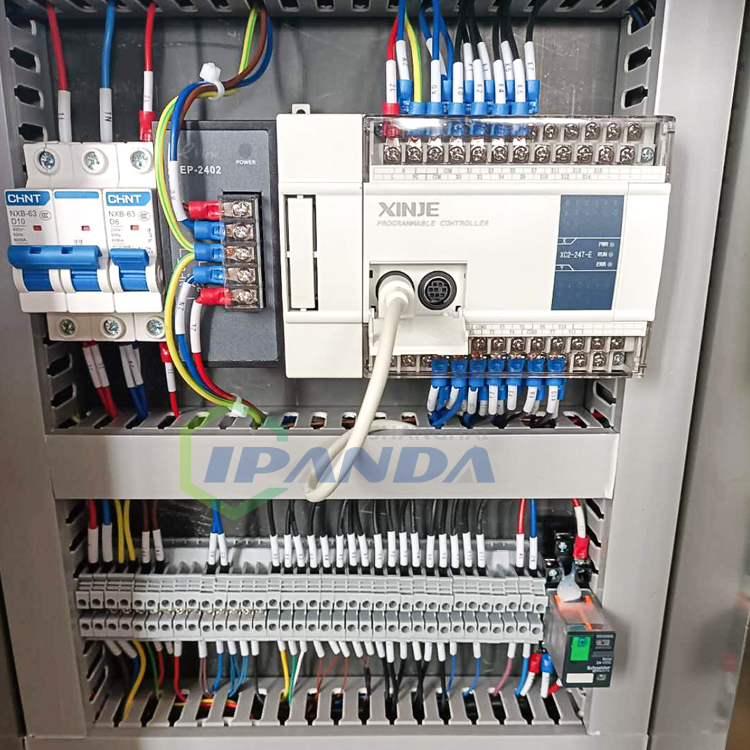

4)using PLC control and touch screen operation, the display is intuitive and easy to operate.

5) The machine can vacuum the bag before filling, reasonably extend the product shelf life, and can also install the nitrogen filling system after filling according to customer requirements (vacuum and nitrogen filling functions are not standard).