3-10ml PRP Plastic Test Tube Filler Detection Reagent Capping Labeling Filling Machinery

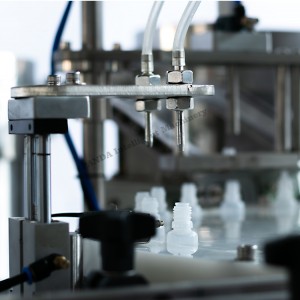

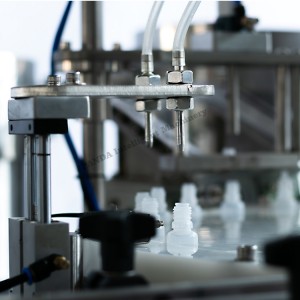

filling and capping machine is a compact filling line equipment.which is mainly applicable to the filling and capping of plastic bottles in medical, pharmaceutical and chemical industries. Automatically complete filling. capping, capping, bottle out, etc.The equipment is suitable for products that are easy to pour and jam bottles on the conveyor belt.

It’s a series of products specially designed for biochemical reagent bottles. It is composed of host, rotary conveying,clamping conveying and bottle holder. It is suitable for all products in Hitachi series.The design adopts peristaltic pump for filling, and the measurement is accurate; The swing arm is used to hook the upper cover, and the positioning is accurate;Pneumatic control is adopted to clamp the screw cap, which will not cause wear to the shape of the bottle cap;The height and clamping force of the screw head are easy to adjust and control.

| Applied Bottle | 0.5-10 ml |

| Productive Capacity | 20-60pcs/min

|

| Filling Tolerance | 1% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 110/220/380V ,50/60HZ |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

1. Adopting peristaltic pump to fill, suitable for various liquid filling, it's very easy quick to dismantle liquid pipes for washing or replacement, no pollution, saving materials & enhancing working efficiency.

2. With humanized design, filling dosage can be directly adjusted on touch screen, easy to adjust for different bottles, convenient & easy to operate.

3. Adopting grab type servo capping heads, capping torque can be easily adjusted, with nice capping effect, reliable & delicate.

4. With PLC & touch screen to control, formal saving, auto counting function, no bottle, no filling, auto fault alarm, easy to link production line, with high automation.

5. Mainly made of top-quality famous brands for spares, reliable & durable.

This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design;

Peristaltic pump filling, high cleanliness, in line with medical health standards.

Adopt a swing lifting cam, lifting and swinging automatically insert the cap, the cap is automatically arranged by the vibration plate and automatically sent to the uploading cap station through the loading cap

The capping head adopts mechanical claw cover (servo motor controlled capping claw),the capping head Torque and torque are controlled by servo, and torque servo control.

Cap vibrating plate used to arrange cap automatically

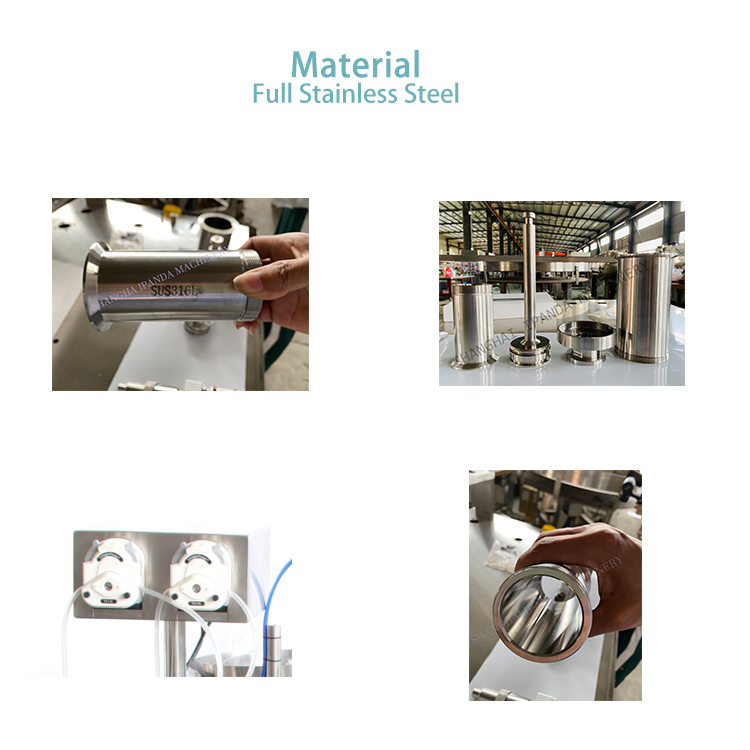

All action is controlled by PLC and Touch screen. The surface of machine is SUS304, material contacted with liquid is 316L stainless steel, can be connect with labeling machine.