2021 China New Design Liquid Filling Equipment - Automatic Edible Cooking Vegetable Oil Bottle Filler Palm Oil Filling Machine – Ipanda

2021 China New Design Liquid Filling Equipment - Automatic Edible Cooking Vegetable Oil Bottle Filler Palm Oil Filling Machine – Ipanda Detail:

Product Display

Overview

The piston filling machine can be connected with filling line,and mainly suitable for viscosity liquids.It adopts integrated design, using high quality electrical components such as PLC, a photoelectric switch, touch screen and high quality stainless steel, plastic parts. This machine is good quality. System operation, convenient adjustment, friendly man machine interface, the use of advanced automatic control technology, in order to achieve a high precision liquid filling.

Parameter

| Material | SS304/316L |

| Bottle Material | PET/PE/PP/Glass/Metal |

| Bottle Shape | Round/Square/Unique Square |

| Capping Method | Screw cap, Press cap, Twisting Cap |

| Bottle Components | Rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps |

| Control System | PLC and touch screen |

| Filing Precision | ±1% |

| Filling material | Oil,cooking oil,engine oil etc. |

| Power Supply | 220V/380V 50/60HZ |

| Filling Speed | 1000-6000 bottles per hour(Customized) |

| Filling Nozzles | 2/4/6/8/10/12(Customized) |

| Dosing System | Piston pump |

| Filling Capacity | 100-5000ml(Customized) |

| Air Supplier | 0.6-0.8MPa |

| Power | 2.0KW |

| Weight | 500kg(Customized) |

| Dimension(mm) | 2500*1400*1900mm (Customized) |

Features

(1) Automactic liquid filling machine,Small size, reasonable design, easy operation, stable performance, low failure rate;

(2) The whole machine is made of high-quality stainless steel. The 304/316L stainless steel material is used in contact with the material to meet the GMP hygienic requirements.

(3) Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

(4) There are filling volume adjustment handles, filling speed adjustment knobs, which can adjust the filling volume and filling speed arbitrarily; the filling precision is high;

(5) According to the requirements of the environment, it can be changed to a full-air-explosion-proof type. It is completely de-energized and safer.

(6) According to customer needs, customize the production of 4 heads, 6 heads, 8 heads and 12 heads.

(7) Plastic bottles and glass bottles are customized according to customer requirements

Application

It is used for automatic filling of various liquids into bottles.Such as oil,cooking oil,sunflower oil,vegetable oil,engine oil,car oil,motor oil.

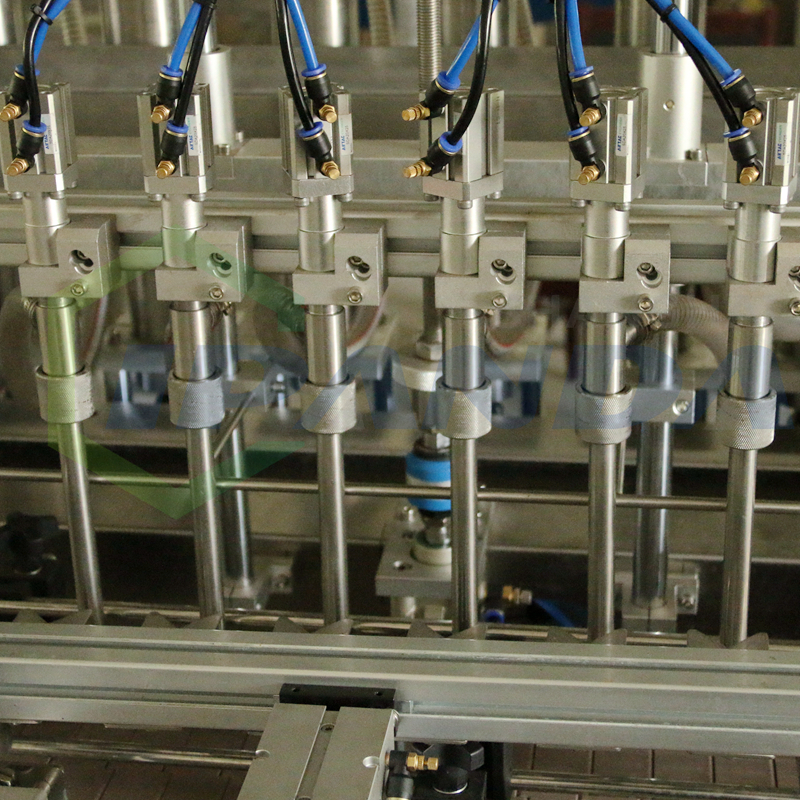

The Machine Details

Piston cylinder

According to customer production capacity requirements could make different size cylinder

Filling system

Filling nozzle adopt bottle mouth diameter custom made,

Filling nozzle are with suck-back function, to avoid leakage suitable material oil, water, syrups, and some other material with good fluidity.

Oil use tree way valve

1. Connecting among tank, rotaty valve, position tank all with fast remove clip.

2. Adopt oil use three way valve, which is suitable for oil, water, and material with good fuidity, the valve is special designed for oil without leakage, ensure high accuracy.

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Photoelectric sensor and pneumatic door coordinate control ,lack bottle ,pour bottle all has automatic protection .

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We've been an energetic corporation with wide market for 2021 China New Design Liquid Filling Equipment - Automatic Edible Cooking Vegetable Oil Bottle Filler Palm Oil Filling Machine – Ipanda , The product will supply to all over the world, such as: Bhutan, Spain, Spain, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.