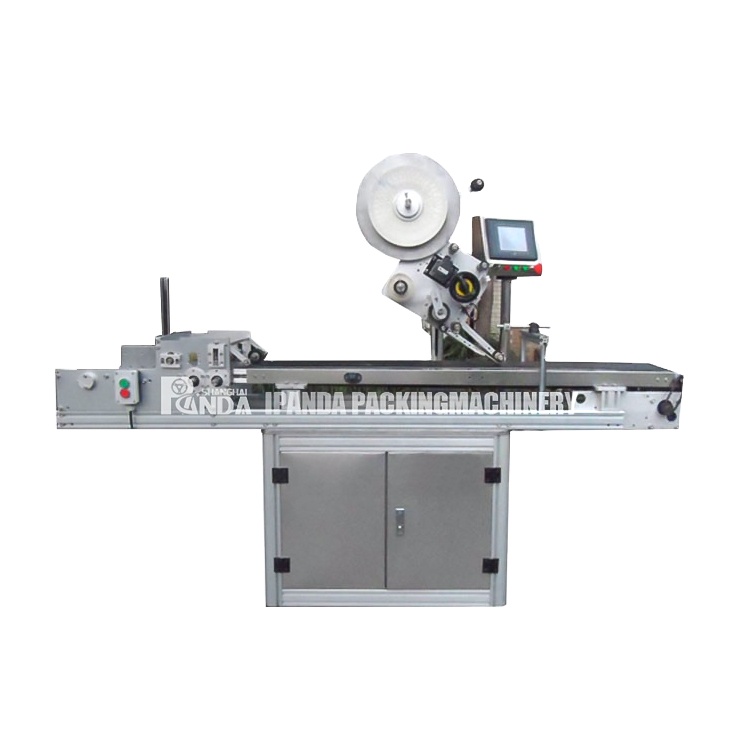

18 Years Factory Beer Label Machine - Multi Side Bottle Top Flat Surface Labeling Machines Automatic Label Machine – Ipanda

18 Years Factory Beer Label Machine - Multi Side Bottle Top Flat Surface Labeling Machines Automatic Label Machine – Ipanda Detail:

Product Display

Overview

Labels suitable for flat products are self-adhesive labels for roll machines. Such as hardware, electronics, stationery, food, medicine, cosmetics, daily necessities, plastic bottles, glass bottles, drums and other products in chemical plants.

Specific products such as: bread, tortoise shell cover, ice cream cover, battery, flat bottle shampoo, flat bottle shower gel, CD box, CD bag, square box cotton swabs, lighter, correction fluid, paint bucket, carton, etc.

Main Technical Parameters

| Machine size | L2000xW550xH1600mm |

| Output speed | 60-350PCS/min (Depends materials and labels) |

| Height Label Object | 30-210mm |

| Thickly Label Object | 20- 120mm |

| Label Height | 15- 200 |

| Label Length | 25- 300 |

| Pastes the sign precision | ±1mm |

| Roll inside | 76mm |

| Roll Outside Diameter | 300mm |

| Power Supply | 220V50/60HZ 1 .5KW |

| Weight | 180kg |

Features

● The whole machine is made of S304 stainless steel and anodized high-grade aluminum alloy.

● The labeling head is driven by an advanced stepping motor.

● All electric eyes are high-grade electric eyes made in Japan or West Germany.

● PLC cooperates with man-machine interface control.

● The labeling position can be adjusted front and back, height and height.

● Applicable paper rolls have an inner diameter of Φ76mm and an outer diameter of Φ360mm or less.

● Conveyor belt width: 137mm (widened size can be customized according to customer requirements).

● Applicable label specifications: bottom paper width 20-130mm (widened size can be customized according to customer requirements).

● Labeling accuracy ±1mm (except for the error between the label and the object).

The Machine Details

Simple operation panel can be used to adjust and control

working data,easy to operate and reduce working error greatly.

Electric eye can detect materials once they pass through.lt will notwork unless the material is detected.This prevents from missing materials and wasting labels.

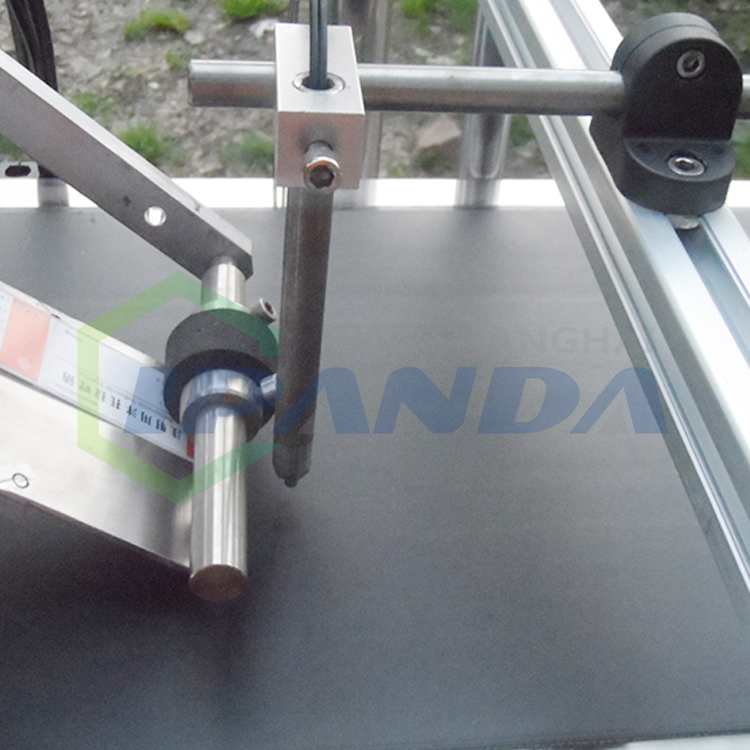

Label bar helps to adjust the labeling position while the label separating blade can separate labels well ,these all help to improve the working quality.

These two rotary knob is used to adjust the horizontal labeling position.

The conveyor is used to transfer materials.The working speed is adjustable,operator can adjust the speed according to their need.The width of feeding inlet can be adjusted according to the material.

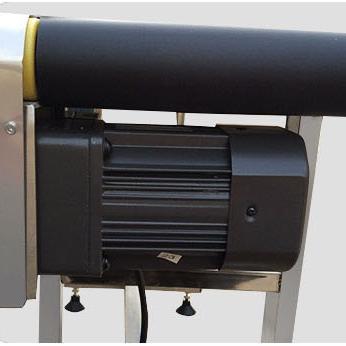

Powerful motor make the machine work stably and low noise.lt ensure the longer working time.

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for 18 Years Factory Beer Label Machine - Multi Side Bottle Top Flat Surface Labeling Machines Automatic Label Machine – Ipanda , The product will supply to all over the world, such as: Iraq, Toronto, St. Petersburg, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!